Fabric for gravity blanket and gravity blanket

A technology for gravity and blankets, applied in the field of textiles, can solve the problems of ash absorption by gravity blankets, and achieve the effects of improving antistatic properties, reducing surface resistivity, and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

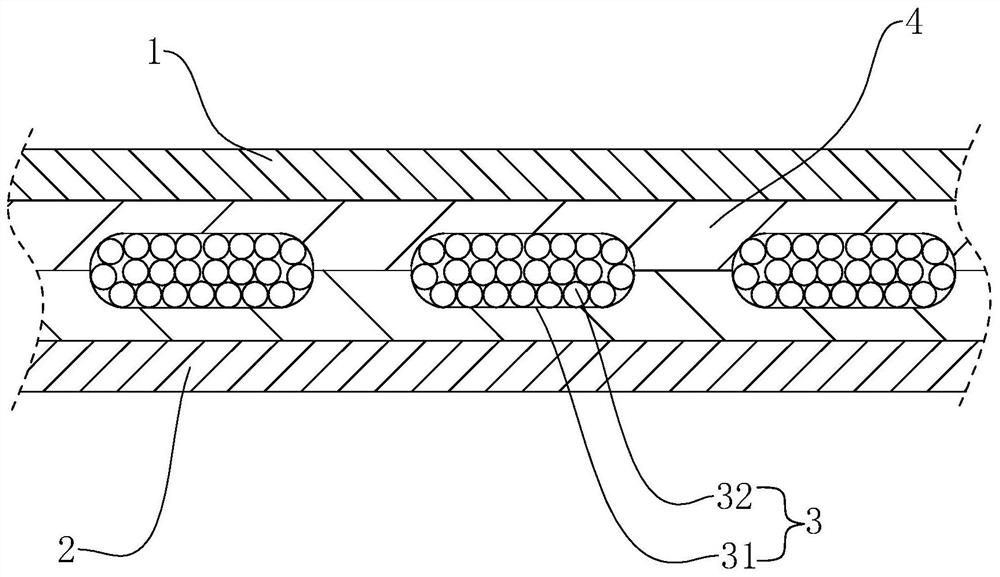

[0047] The embodiment of the present application discloses a fabric for a gravity blanket, which is formed by weaving textile yarns and conductive yarns. Among them, textile yarn is divided into textile weft and textile warp according to different uses. Conductive yarns are used as wefts and used in conjunction with textile wefts; the ratio of conductive yarns to textile wefts is 1:8 and the two are arranged at intervals (that is, 8 textile wefts are followed by 1 conductive yarn, and then 8 root textile weft, in this way). The fabric for gravity blankets is obtained by interweaving conventional warp and weft threads.

[0048] In this embodiment, all the textile yarns are wool yarns spun with wool fibers as the base material, which can not only endow the fabrics for gravity blankets and gravity blankets with good warmth retention, but also have better human affinity than chemical fibers. sex and environmental protection.

[0049] The use of conductive yarn is conducive to t...

Embodiment 2-12

[0062] As shown in Table 1, Examples 2-12 are basically the same as Example 1, except that the ratio of raw materials for preparing conductive yarns is different.

[0063] Table 1 Example 1-18 raw material ratio

[0064] serial number Polymer Masterbatch polyaniline sodium pyrophosphate Conductive powder Example 1 100 10 4 0 Example 2 100 12 4.8 0 Example 3 100 15 6 0 Example 4 100 18 7.2 0 Example 5 100 20 8 0 Example 6 100 25 10 0 Example 7 100 30 12 0 Example 8 100 35 14 0 Example 9 100 18 4 0 Example 10 100 18 6 0 Example 11 100 18 10 0 Example 12 100 18 15 0 Example 13 100 18 7.2 3 Example 14 100 18 7.2 6 Example 15 100 18 7.2 8 Example 16 100 18 7.2 10 Example 17 100 18 7.2 12 Example 18 100 18 7.2 15

[0065] Note: The unit of the addition amount of each raw material component is kg.

Embodiment 13-18

[0067] As shown in Table 1, Examples 13-18 are basically the same as Example 4, except that conductive mica powder is added in Examples 13-18. Conductive mica powder is a kind of conductive powder, which can improve the conductivity of the obtained conductive fiber, which is beneficial to the dissipation of electrostatic charges, thereby improving the antistatic property of the obtained fabric. The main difference between Examples 13-18 is that the amount of conductive mica powder added is different.

[0068] At the same time, the conductive mica powder in Examples 13-18 was melt-spun after being mixed with polylactic acid masterbatch, polyaniline, and sodium pyrophosphate in step (1) of the preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com