Baking-resistant salad sauce preparation system and preparation method

A baking-resistant, shell-resistant technology, applied in mixing methods, chemical instruments and methods, food ingredients as emulsifiers, etc., can solve the problems of poor emulsion stability, large emulsion particles, easy collapse of salad dressings, etc., and achieve good stability, The effect of small emulsion particles and fine and smooth product organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

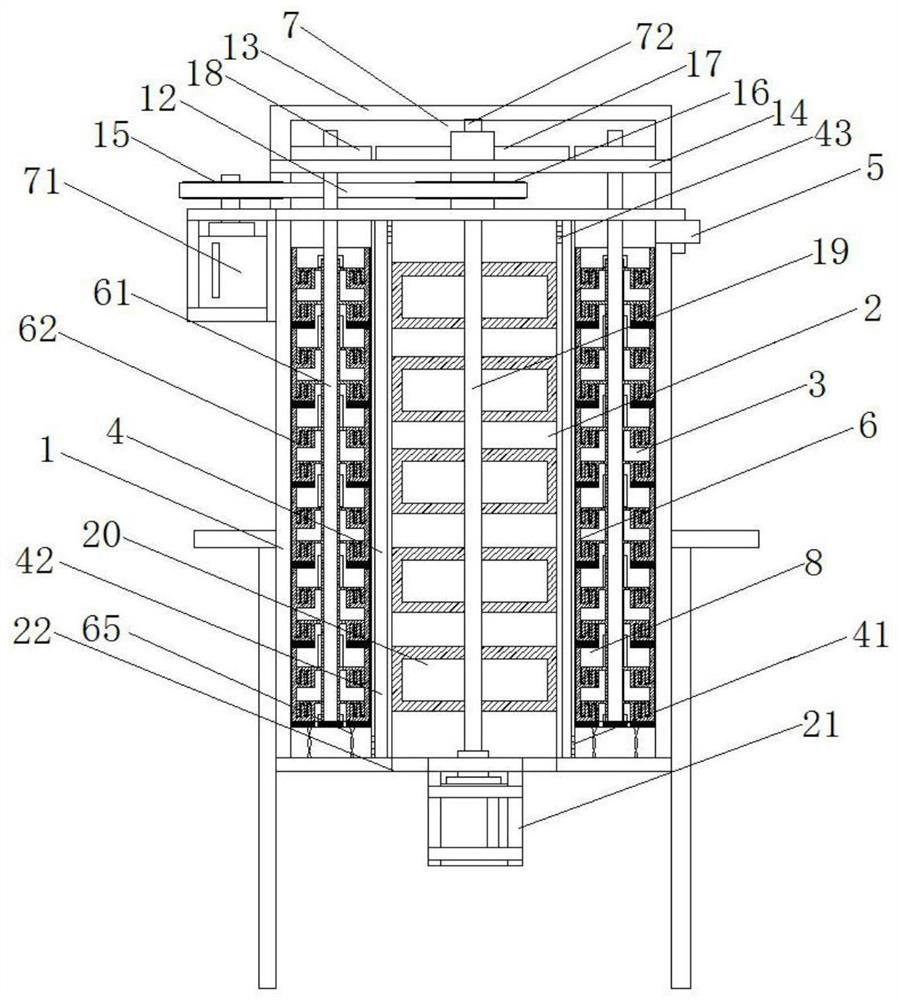

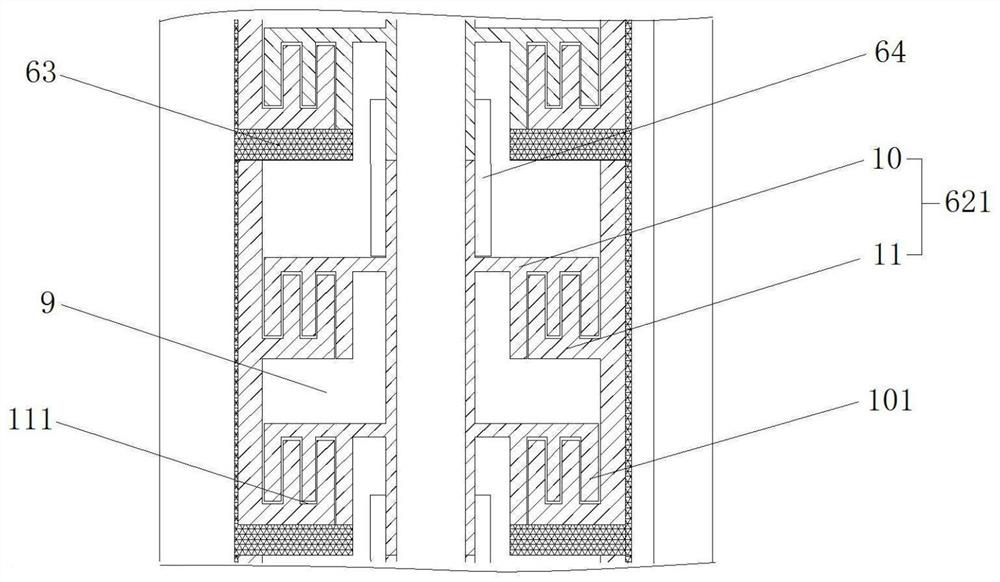

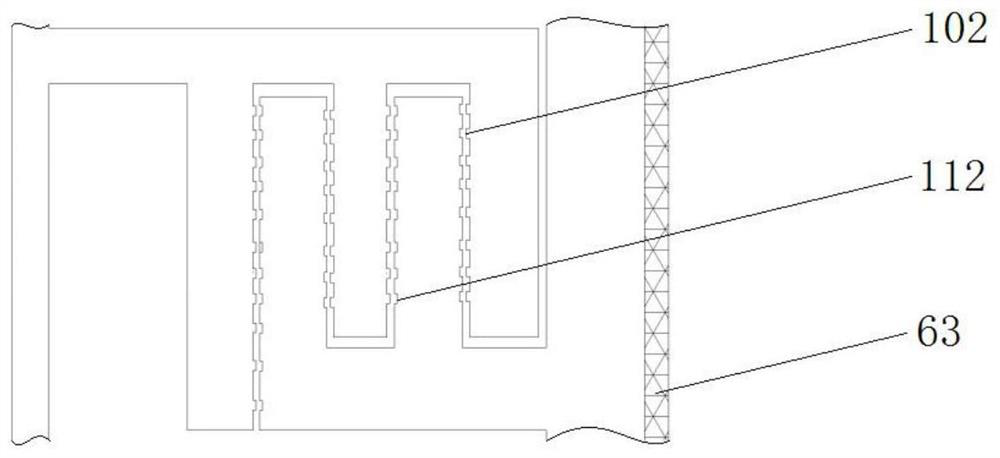

[0046] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is some embodiments of the present invention, but not all of them. Based on the implementation manners in the present invention, all other implementation manners obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention. Accordingly, the following detailed description of the embodiments of the invention provided in the accompanying drawings is not intended to limit the scope of the claimed invention, but merely represents selected embodiments of the invention. Based on the implementation manners in the present invention, all other implement...

Embodiment 1

[0080] The processing technology of salad dressing in the present embodiment, comprises the steps:

[0081] Step 1: Add 27.5 parts by weight of pure water, 12 parts by weight of sterilized egg yolk and 10.5 parts by weight of white sugar into the first shearing device with a rotor speed of 2000-3000r / min, wait for 1-2min to mix and melt evenly After that, add 1.5 parts by weight of table salt, 0.1 parts by weight of calcium chloride, 0.3 parts by weight of sodium glutamate, 0.7 parts by weight of mustard, 0.2 parts by weight of white pepper and 2 parts by weight of compound enzyme preparation;

[0082] Step 2: Add 1.7 parts by weight of cross-linked hydroxypropyl compound modified starch, 0.1 parts by weight of gellan gum and 8 parts by weight of vegetable oil to the second shearing device whose rotor speed is 5000-6000r / min, and wait to be sheared During 3-5 minutes, slowly add 25 parts by weight of vegetable oil;

[0083] Step 3: After the two phases of oil and water are mi...

Embodiment 2

[0087] The processing technology of salad dressing in the present embodiment, comprises the steps:

[0088] Step 1: Add 20 parts by weight of pure water, 10 parts by weight of sterilized egg yolk and 10 parts by weight of white sugar into the first shearing device with a rotor speed of 2000-3000r / min, wait for 1-2 minutes to mix and melt evenly After that, add 1 weight part of salt, 0.1 weight part of calcium chloride, 0.2 weight part of sodium glutamate, 0.5 weight part of mustard, 0.1 weight part of white pepper and 1 weight part of compound enzyme preparation;

[0089] Step 2: Add 2.5 parts by weight of cross-linked hydroxypropyl compound modified starch, 0.2 parts by weight of gellan gum and 11 parts by weight of vegetable oil to the second shearing device whose rotor speed is 5000-6000r / min, and wait to be sheared At 3-5 minutes, slowly add 20 parts by weight of vegetable oil;

[0090] Step 3: After the two phases of oil and water are mixed at the bottom of the shearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com