Method for surfacing high-hardness wear-resistant layer on blow-in drill bit

A wear-resistant layer and high-hardness technology, which is applied in the direction of drill bits, welding equipment, welding media, etc., can solve the problem of cemented carbide block falling off, and achieve the effects of increased bonding strength, improved wear resistance and hardness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

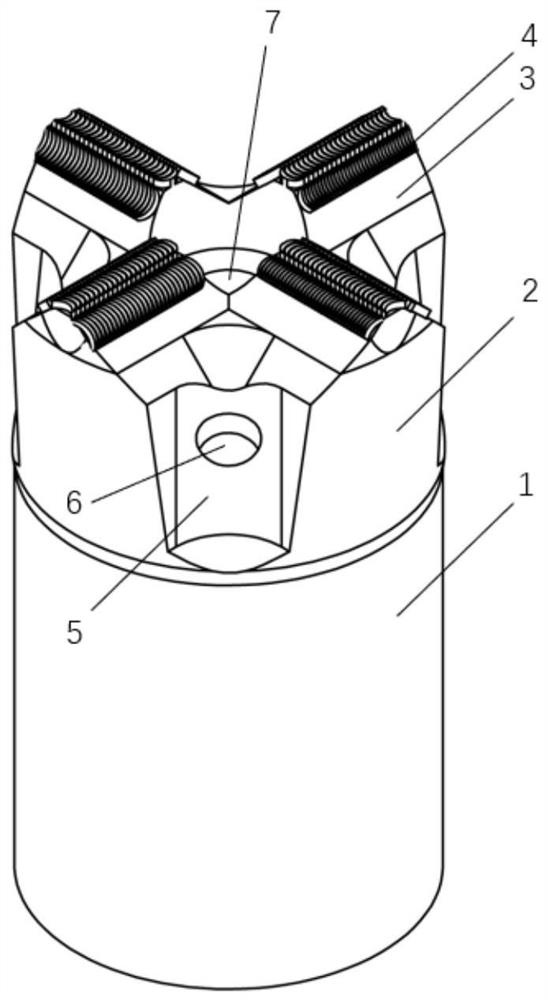

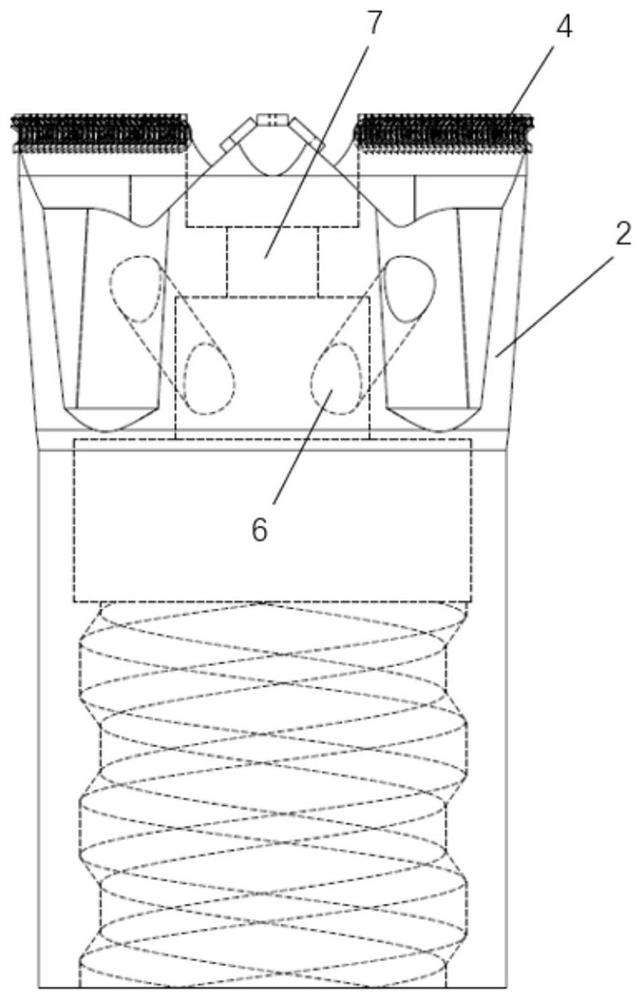

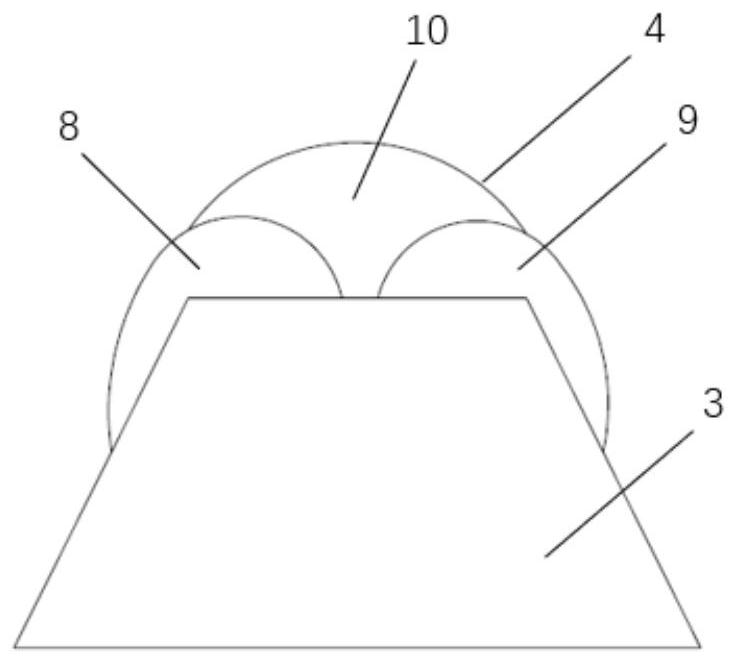

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] A method for surfacing a high-hardness wear-resistant layer for an open-furnace drill bit of the present invention comprises the following steps:

[0030] 1) Selection of bonding phase: High-temperature cobalt-based bonding phase is used as the high-temperature resistant bonding phase, and the bonding phase includes the following components in mass percentage: C (2.6-3.0), Cr (30-33), Si (1.0- 2), W(14-17), Fe(<3), Mo(3-5), Ni(3.5-4.0), Mn(0.7-1.2), Co(balance), alloy hardness greater than 55HRC, at 800 It also has wear resistance in high temperature environments.

[0031]2) Selection of hard phase: WC with a hardness of 1800HRC is used as the hard phase for abrasive wear. The hard phase includes the following components in mass percentage: W (95-96), LC (3.8-4.1); The mass ratio of phase to binder phase is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com