Light overlay gypsum building material and preparation method thereof

A gypsum and light-weight technology, which is applied in the field of light-weight overlay gypsum building materials and its preparation, can solve the problems of high volume density of putty materials, high cost of putty raw materials, uneven color of batch scraping, etc., and achieve low cost and good protection , the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

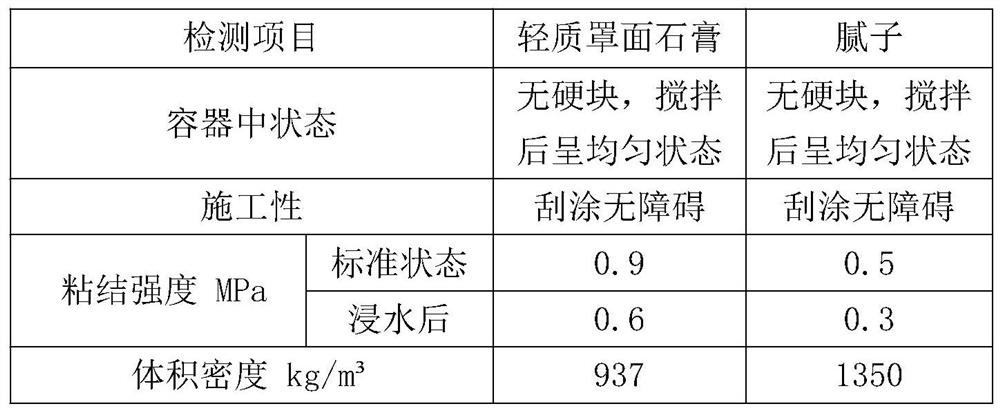

Image

Examples

Embodiment 1

[0020] A lightweight overlay gypsum building material, comprising the following raw materials in parts by weight: 900 parts of gypsum, 60 parts of perlite, 4 parts of lime calcium, 1.5 parts of hydroxypropyl methylcellulose, 0.4 part of special lubricant for gypsum, retarding dose 0.1 part.

[0021] Wherein, the special lubricant for gypsum is pentaerythritol.

[0022] Wherein, the retarder is a mixture of layered crystalline sodium disilicate and sodium fluorosilicate.

[0023] Wherein, the ratio of the mixture of layered crystalline sodium disilicate and sodium fluorosilicate in the retarder is 1:1.

[0024] The preparation method of the above-mentioned lightweight overlay gypsum building material, the steps are as follows:

[0025] 1) First mix hydroxypropyl methylcellulose, special lubricant for gypsum, and setting retarder to obtain mixed additives;

[0026] 2) After pulverizing the gypsum, perlite, lime calcium and the mixed additive obtained in step 1), mix evenly to...

Embodiment 2

[0030] A lightweight overlay gypsum building material, comprising the following raw materials in parts by weight: 950 parts of gypsum, 65 parts of perlite, 4.5 parts of lime calcium, 1.8 parts of hydroxypropyl methylcellulose, 0.5 parts of special lubricant for gypsum, retarded 0.7 part of the agent.

[0031] Wherein, the special lubricant for gypsum is a mixture of pentaerythritol and magnesium lauryl sulfate.

[0032] Wherein, the retarder is a mixture of layered crystalline sodium disilicate and sodium fluorosilicate.

[0033] Wherein, the ratio of the mixture of layered crystalline sodium disilicate and sodium fluorosilicate in the retarder is 2:1.

[0034] The preparation method of the above-mentioned lightweight overlay gypsum building material, the steps are as follows:

[0035] 1) First mix hydroxypropyl methylcellulose, special lubricant for gypsum, and setting retarder to obtain mixed additives;

[0036] 2) After pulverizing the gypsum, perlite, lime calcium and t...

Embodiment 3

[0039] A lightweight overlay gypsum building material, comprising the following raw materials in parts by weight: 1,000 parts of gypsum, 70 parts of perlite, 5 parts of lime calcium, 1.7 parts of hydroxypropyl methylcellulose, 0.5 parts of special lubricant for gypsum, retarded 0.4 parts of the agent.

[0040] Wherein, the special lubricant for gypsum is pentaerythritol.

[0041] Wherein, the retarder is a mixture of layered crystalline sodium disilicate and sodium fluorosilicate.

[0042] Wherein, the ratio of the mixture of layered crystalline sodium disilicate and sodium fluorosilicate in the retarder is 2:1.

[0043] The preparation method of the above-mentioned lightweight overlay gypsum building material, the steps are as follows:

[0044] 1) First mix hydroxypropyl methylcellulose, special lubricant for gypsum, and setting retarder to obtain mixed additives;

[0045] 2) After pulverizing the gypsum, perlite, lime calcium and the mixed additive obtained in step 1), mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com