A combined luminescent material and its application

A technology of light-emitting materials and fluorescent materials, applied in the field of combined light-emitting materials, can solve the problems of low external quantum efficiency of organic light-emitting diodes, hindering the theoretical efficiency of devices, and limiting the promotion of diodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

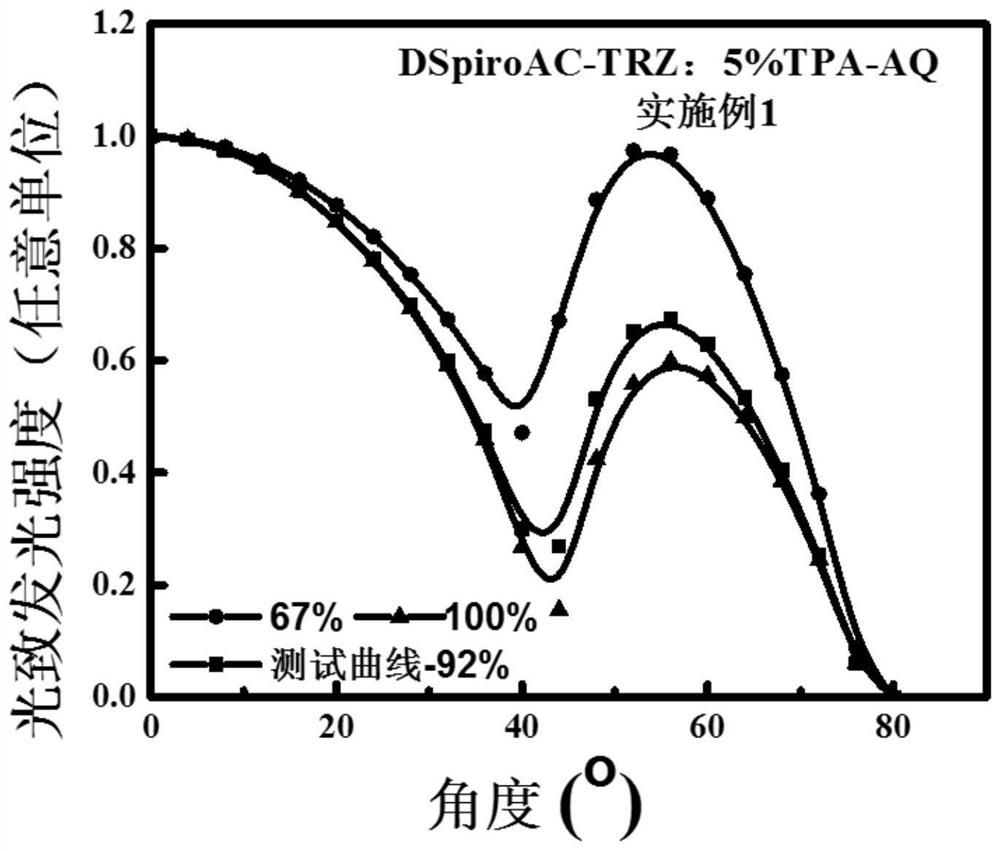

[0098] This embodiment provides a combined luminescent material, wherein:

[0099] Including 5wt% guest material, and 95wt% host material;

[0100] The host material is DSpiroAC-TRZ, which is thermally activated delayed fluorescence with horizontal orientation of high transition dipole moment, and the single-triplet exchange energy is 0.04 eV. The preparation method is shown in formula (1);

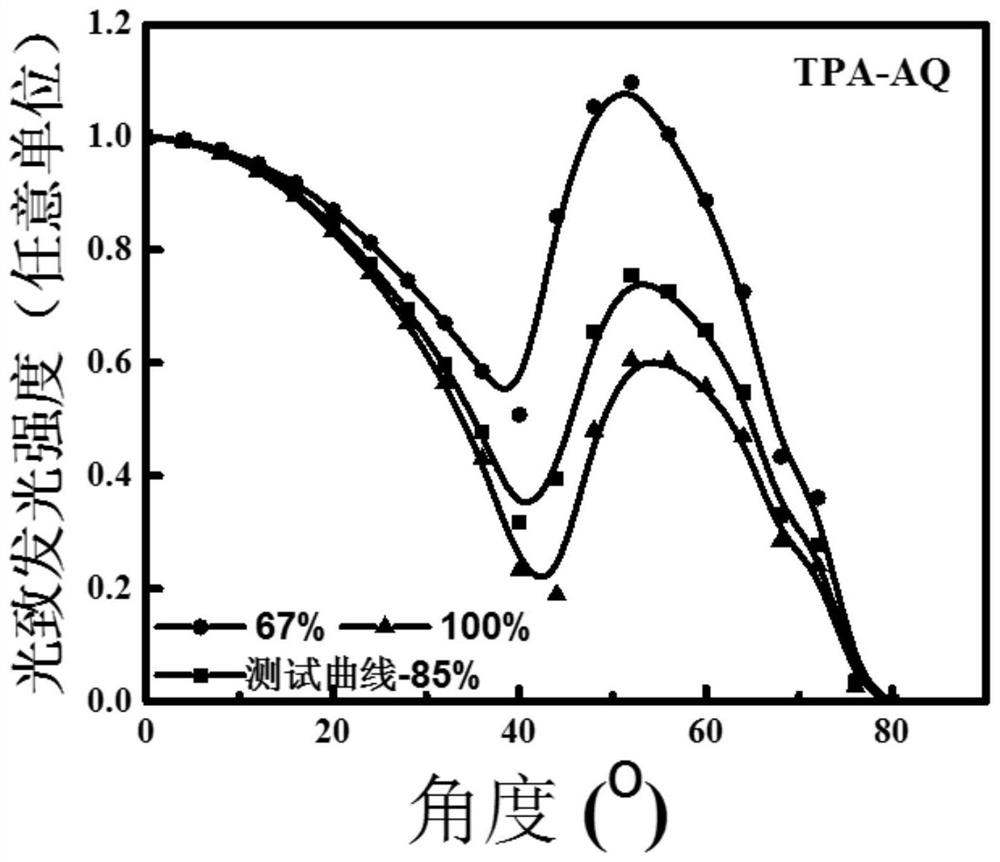

[0101] The guest material is TPA-AQ, and the preparation method is shown in formula (8).

Embodiment 2

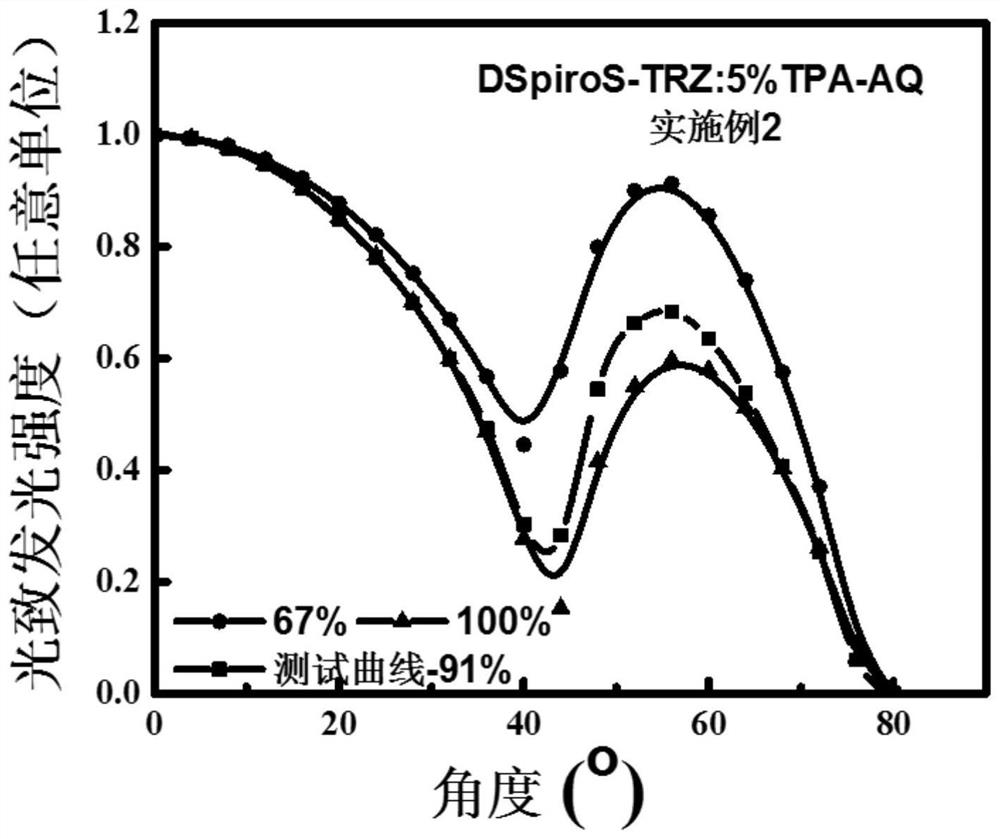

[0103] This embodiment provides a combined luminescent material, wherein:

[0104] Including 5wt% guest material, and 95wt% host material;

[0105] The host material is DSpiroS-TRZ, which is thermally activated delayed fluorescence with a high transition dipole moment horizontal orientation, and the single-triplet exchange energy is 0.05 eV. The preparation method is shown in formula (2);

[0106] The guest material is the same as that used in Example 1.

Embodiment 3

[0108] This embodiment provides a combined luminescent material, wherein:

[0109] Including 5wt% guest material, and 95wt% host material;

[0110] The main material is the same as in Example 1;

[0111] The guest material is DBXZ-2FDBPZ, and the preparation method is shown in formula (9).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com