Environment-friendly degradable release film

An environmentally friendly, release film technology, applied in the direction of coating, etc., can solve the problems of increasing the toughness of degradable environmental protection release film, achieve excellent biodegradability, good tensile strength and ductility, and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

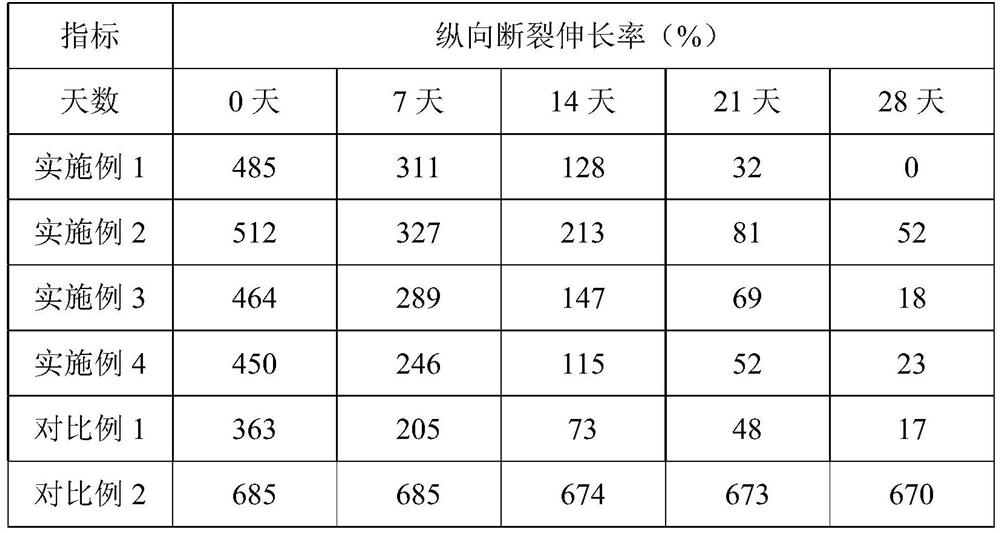

Examples

Embodiment 1

[0025] An environment-friendly degradable release film comprises a base material original film layer and a release agent coating, and the material of the base material original film layer is a PLA / PBAT blend material.

[0026] Wherein, the PLA / PBAT blend material comprises the following components by weight ratio: 30 parts of PLA, 90 parts of PBAT, 4 parts of plasticizer, 4 parts of epoxy soybean oil, and 3 parts of chain extender.

[0027] And, the plasticizer is acetyl tributyl citrate.

[0028] Also, the chain extender is ADR4370S.

[0029] And, described release agent coating is stearate release agent coating.

[0030] Further, the preparation method of the environment-friendly degradable release film comprises the following steps:

[0031] The raw materials in the PLA / PBAT blended material are weighed in proportion, blended and extruded by a twin-screw extruder, pelletized, and the original film layer of the base material is formed by a film blowing machine;

[0032] A...

Embodiment 2

[0037] An environment-friendly degradable release film comprises a base material original film layer and a release agent coating, and the material of the base material original film layer is a PLA / PBAT blend material.

[0038] Wherein, the PLA / PBAT blend material comprises the following components by weight ratio: 10 parts of PLA, 70 parts of PBAT, 2 parts of plasticizer, 2 parts of epoxy soybean oil, and 1 part of chain extender.

[0039] And, the plasticizer is acetyl tributyl citrate.

[0040] Also, the chain extender is ADR4370S.

[0041] And, the release agent coating is a silicon-free release agent coating.

[0042] Further, the preparation method of the environment-friendly degradable release film comprises the following steps:

[0043] The raw materials in the PLA / PBAT blended material are weighed in proportion, blended and extruded by a twin-screw extruder, pelletized, and the original film layer of the base material is formed by a film blowing machine;

[0044] Ap...

Embodiment 3

[0049] An environment-friendly degradable release film comprises a base material original film layer and a release agent coating, and the material of the base material original film layer is a PLA / PBAT blend material.

[0050] Wherein, the PLA / PBAT blended material comprises the following components by weight ratio: 20 parts of PLA, 80 parts of PBAT, 3 parts of plasticizer, 3 parts of epoxy soybean oil, and 2 parts of chain extender.

[0051] And, the plasticizer is acetyl tributyl citrate.

[0052] Also, the chain extender is ADR4370S.

[0053]And, the release agent coating is a silicon-free release agent coating or a stearate release agent coating.

[0054] Further, the preparation method of the environment-friendly degradable release film comprises the following steps:

[0055] The raw materials in the PLA / PBAT blended material are weighed in proportion, blended and extruded by a twin-screw extruder, pelletized, and the original film layer of the base material is formed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com