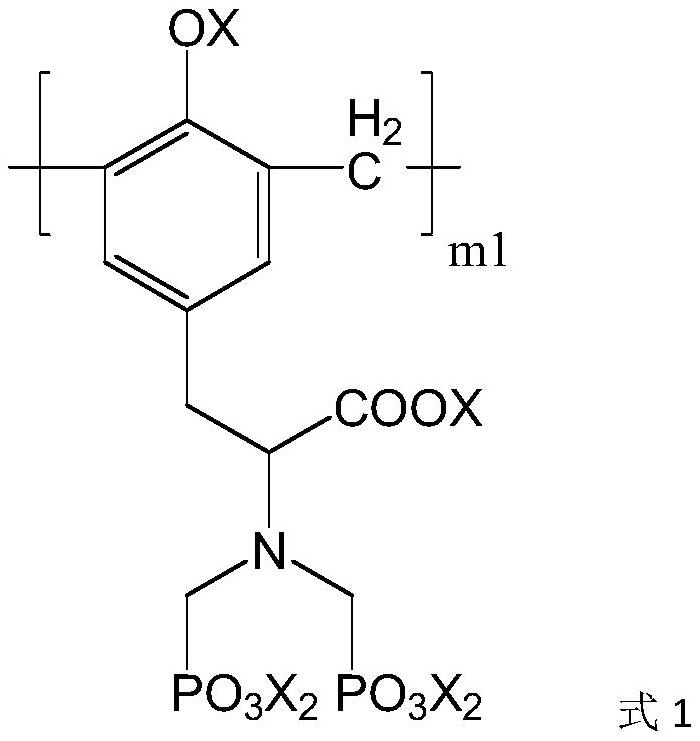

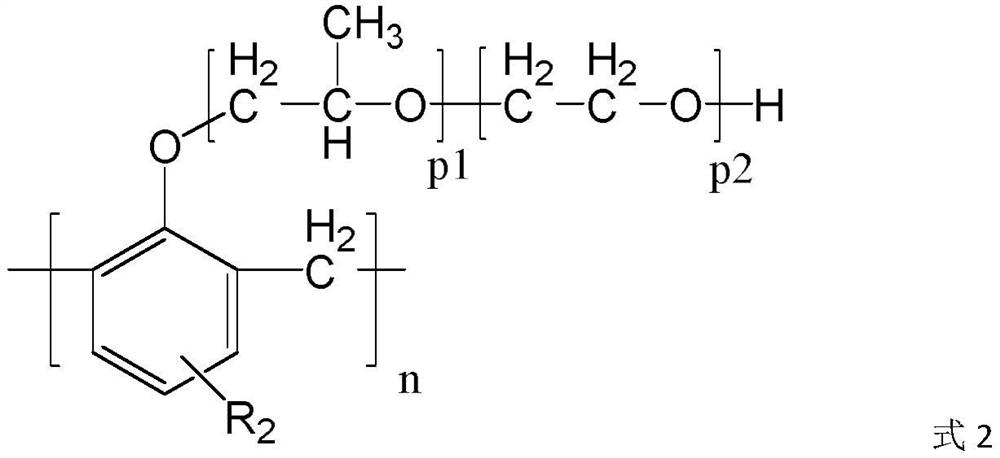

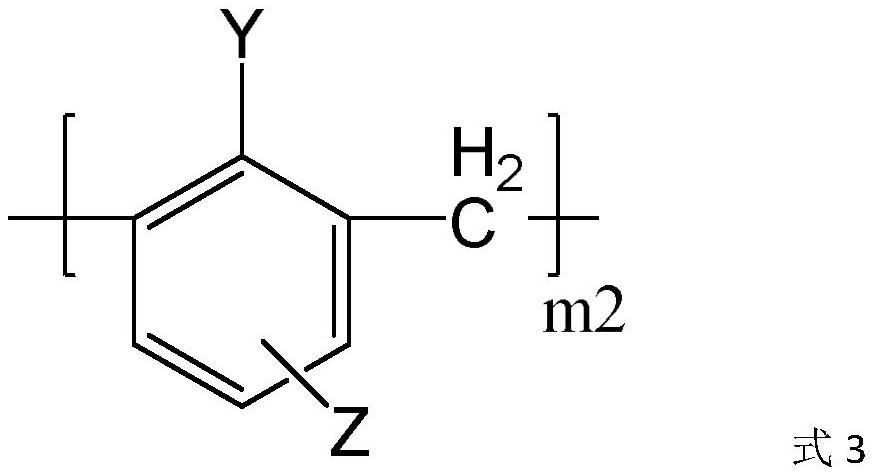

High-adaptability water reducing agent based on biological amino acid as well as preparation method and application of high-adaptability water reducing agent

An amino acid and adaptable technology, applied in the field of building materials, can solve the problems such as the gap in water-reducing performance of monopolyether chain water-reducing agents, and achieve the effects of strong degradability, good adaptability, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Get 130.5 parts of quality tyrosine, 117.4 parts of quality 732 type cation exchange resin (hydrogen type) and 328.1 parts of quality phenoxy macromonomer A-1, mix uniformly in 1600 parts of water, add 118.1 parts of quality sub Phosphoric acid, stir and mix, and then slowly add 194.1 parts of formaldehyde solution by mass, during which the temperature is controlled not to exceed 50 degrees. Afterwards, the temperature was raised to 100°C and condensed for 6 hours. Afterwards, the catalyst was filtered out and neutralized by adding liquid caustic soda with a total acid equivalent of 80% of the reactants to obtain water reducer P-1 with a weight-average molecular weight of 17.6kDa.

Embodiment 2

[0046] Get 108.7 parts of quality tyrosine, 66 parts of quality 732 type cation exchange resin (hydrogen type) and 226.2 parts of quality phenoxy macromonomer A-2, mix uniformly in 2300 parts of water, add 98.4 parts of quality sub- Phosphoric acid, stir and mix, and then slowly add 153.2 parts of formaldehyde solution by mass, during which the temperature is controlled not to exceed 50 degrees. Afterwards, the temperature was raised to 100°C and condensed for 2 hours. Afterwards, the catalyst was filtered out and neutralized by adding liquid caustic soda with a total acid equivalent of 60% of the reactants to obtain a water reducer P-2 with a weight-average molecular weight of 6.7 kDa.

Embodiment 3

[0048] Get 108.7 parts of quality tyrosine, 10.35 parts of p-hydroxybenzoic acid, 87 parts of quality 732 type cation exchange resin (hydrogen type) and 313.2 parts of quality phenoxy macromonomer A-3, mix in 1500 parts of water Evenly, add 98.4 parts by mass of phosphorous acid, stir and mix, then slowly add 150.2 parts by mass of formaldehyde solution, during which the temperature is controlled not to exceed 50 degrees. Afterwards, the temperature was raised to 80°C and condensed for 8 hours. Afterwards, the catalyst was filtered out and neutralized by adding liquid caustic soda with a total acid equivalent of 80% of the reactants to obtain water reducer P-3 with a weight average molecular weight of 13.8kDa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com