Organic silicon foaming connecting coating and preparation method thereof

A technology of organosilicon and hydroxyorganosilicon, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of increasing material costs and increasing construction costs, so as to prolong service life and increase coating Layer thickness, the effect of reducing the number of construction passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

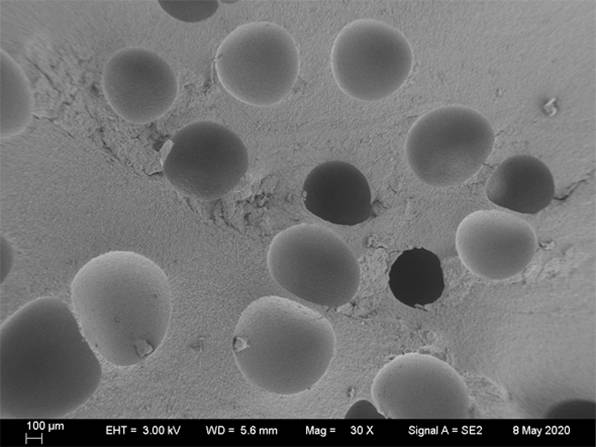

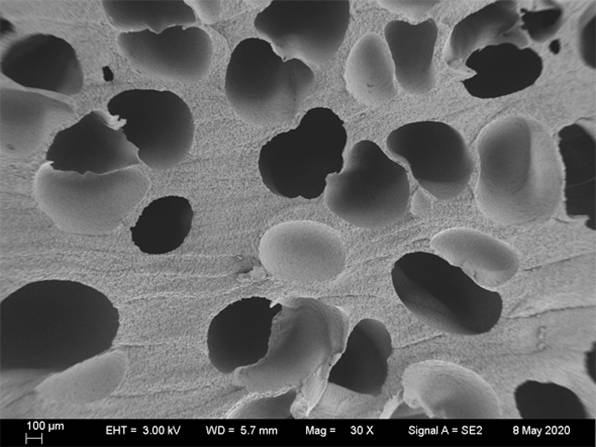

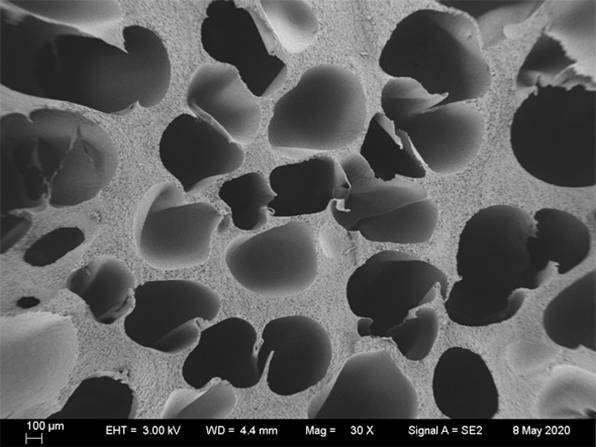

Image

Examples

preparation example Construction

[0025] A preparation method for silicone foam connection coating, comprising the following preparation steps:

[0026] Step 1. Preparation of Component A: Component A is composed of the following components in parts by mass: 10-60 parts of hydroxy silicone resin, 1-5 parts of monobasic organic acid, 10-20 parts of pigment and filler, thixotropic agent 0.5~1 part, 10~20 parts of solvent I; the preparation method of component A is: calculated by mass parts, add 10~60 parts of hydroxyl silicone resin, 1~5 parts of monobasic organic acid, 10 ~20 parts of solvent Ⅰ, the reactor can be a dispersing tank, disperse at a high speed for 15~25 minutes, then add 10~20 parts of pigments and fillers and continue to disperse at a high speed for 3~6 hours, then add 0.5~1 part of thixotropic agent, continue Disperse at high speed for 1~3h, when the fineness of the coating drops to 60~80μm, filter the material;

[0027] Step 2, preparation of component B: component B is composed of the followi...

Embodiment 1

[0042] The ingredients of the A, B and C components of this embodiment are shown in Table 1. The high-speed dispersion method is used to prepare the A and B components. When using, the A, B and C components are blended according to the batching ratio in Table 1. The construction can be carried out after stirring evenly. The connecting paint can be constructed by brush coating, roller coating, high-pressure airless spraying, air spraying and other construction techniques.

Embodiment 2

[0044] The ingredients of the A, B and C components of this embodiment are shown in Table 1. The high-speed dispersion method is used to prepare the A and B components. When using, the A, B and C components are blended according to the batching ratio in Table 1. The construction can be carried out after stirring evenly. The connecting paint can be constructed by brush coating, roller coating, high-pressure airless spraying, air spraying and other construction techniques.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com