Automatic control method and device for straw pyrolysis gasification

A technology of pyrolysis gasification and straw, which is applied in the direction of gasification device feeding tools, gasification process, and production of combustible gas. Effects of cost and operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

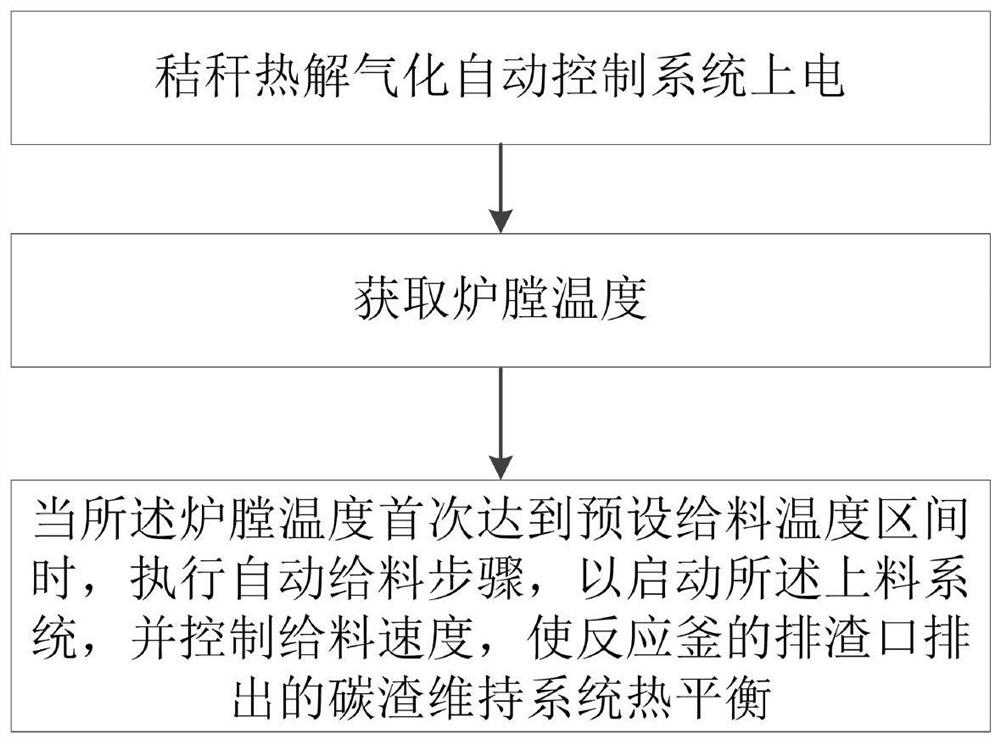

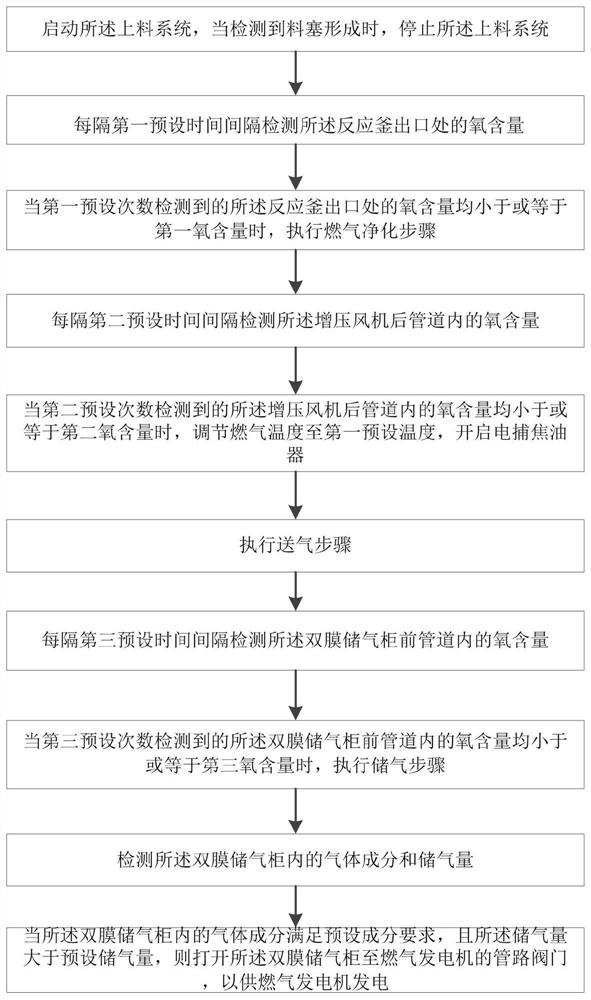

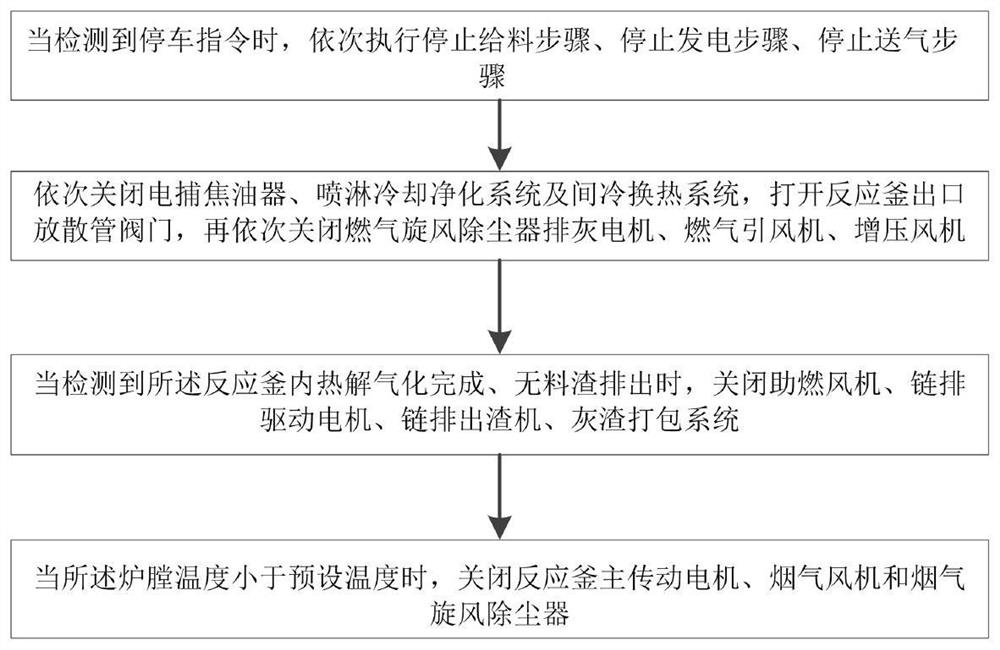

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] Firstly, the straw pyrolysis gasification equipment in the present invention is introduced.

[0041] Such as Figure 4 , Straw pyrolysis gasification equipment includes: hydraulic feeding system, beak feeding system, feeding belt, crusher, flue gas fan, flue gas cyclone dust collector, reaction kettle, discharge pipe, slag outlet, furnace, chain Grate furnace, combustion-supporting fan, reactor main drive motor, chain drive motor, chain slag discharger, ash packing system, booster fan, gas induced draft fan, gas cyclone dust collector, ash discharge motor, electric tar catcher, double Membrane gas storage cabinets, release pipe valves, heat exchangers, spray cooling purification systems and intercooling heat exchange systems, gas g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com