Hemispherical micropore array substrate for three-dimensional cell sphere culture and preparation method of hemispherical micropore array substrate

A three-dimensional cell and microwell array technology, applied in general culture methods, cell culture supports/coatings, biochemical equipment and methods, etc. Collect difficulties and other problems, achieve the effect of simple operation, enhanced collision between cells, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

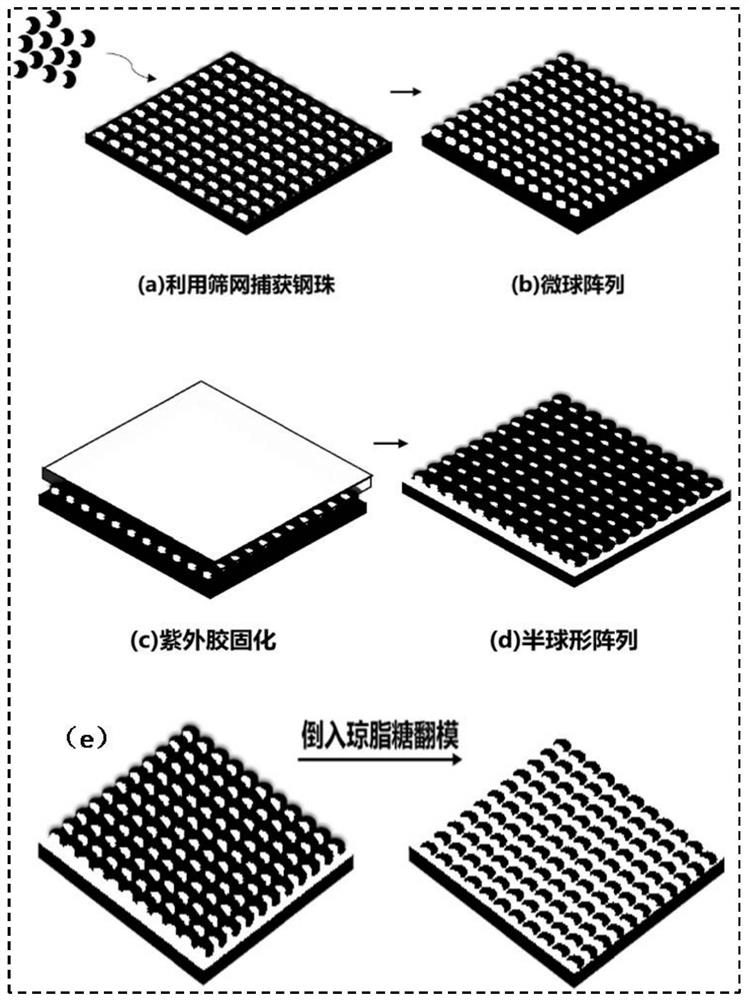

[0044] A preparation method for a hemispherical microwell array substrate for three-dimensional cell spheroid culture, comprising the following steps (refer to figure 1 shown):

[0045] (1) Stick a layer of double-sided adhesive on the surface of the glass, and use the double-sided adhesive to stick the stainless steel screen with a mesh size of 30 mesh on the surface to obtain a sandwich structure of double-sided adhesive-glass-stainless steel screen. Pour excess 400μm stainless steel microspheres into the sieve, capture a single steel ball in a single sieve micropore by scraping, fix a steel ball in each sieve hole, press, so that the steel ball is pasted by double-sided adhesive, and then The stainless steel screen was removed to obtain a plane with microsphere arrays (the front side of which is neatly arranged microsphere arrays).

[0046] (2) Prepare a clean glass substrate (thickness 20mm), apply a layer of UV glue on it with a glue leveler at a speed of 2000rpm, then p...

Embodiment 4

[0059] A preparation method for a hemispherical microwell array substrate for three-dimensional cell spheroid culture, comprising the following steps (refer to figure 1 shown):

[0060] (1) Stick a layer of double-sided adhesive on the surface of the glass, and use the double-sided adhesive to stick the stainless steel screen with a mesh size of 50 mesh on the surface to obtain a sandwich structure of double-sided adhesive-glass-stainless steel screen. Pour excess 300μm stainless steel microspheres into the sieve, capture a single steel ball in a single sieve micropore by scraping, fix a steel ball in each sieve hole, press it so that the steel ball is pasted by double-sided adhesive, and then Pull off the stainless steel screen to obtain a plane with microsphere arrays (the front side is a neatly arranged microsphere array).

[0061] (2) Prepare a clean glass substrate (thickness 20mm), apply a layer of UV glue on it with a glue leveler at a speed of 2000rpm, then press the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com