Construction method for soft rock roadbed in rainy and humid area

A construction method and subgrade technology, applied in basic structure engineering, roads, roads, etc., can solve the problems of insufficient stiffness, deterioration of subgrade performance, uneven deformation of subgrade deformation, etc., so as to improve the overall modulus and stiffness, and avoid secondary opening. The effect of digging and drying to ensure strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

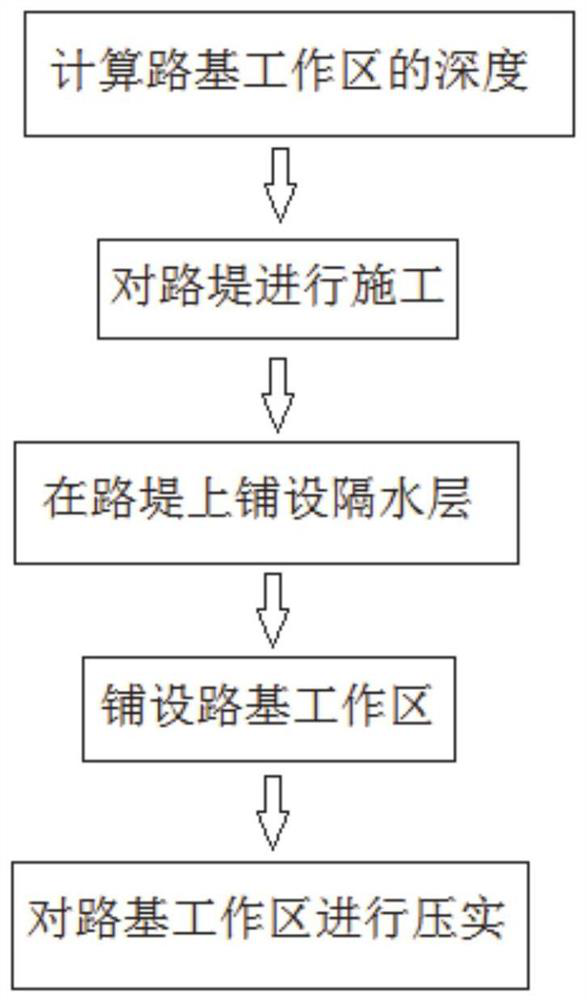

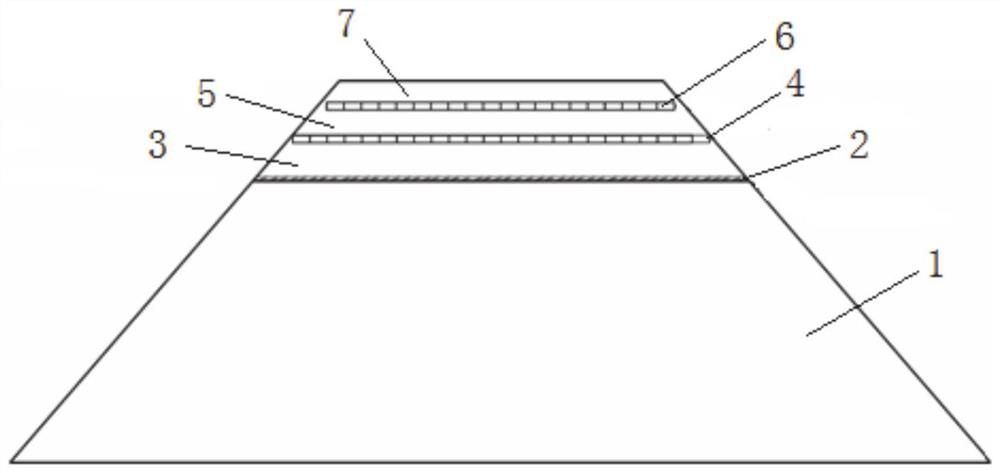

[0036] This embodiment discloses a soft rock subgrade construction method in rainy and humid areas, such as figure 1 As shown, the required depth of the subgrade work area is pre-calculated. After the embankment construction is completed, the subgrade work area is constructed according to the calculated depth of the subgrade work area.

[0037] In this embodiment, the calculation method of the depth of the subgrade work area is:

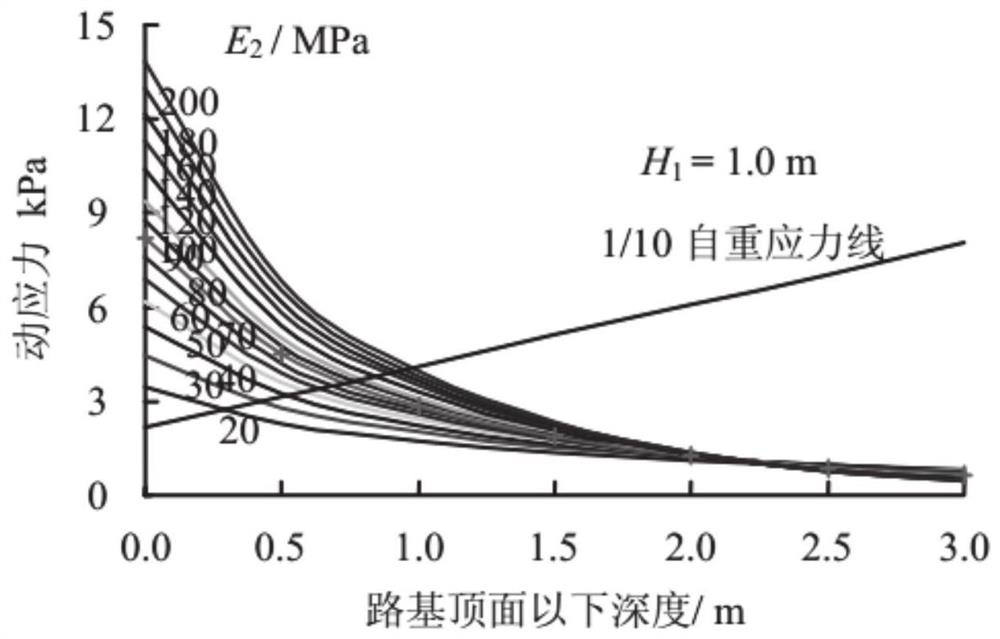

[0038] Firstly, the depth calculation model of the subgrade working area is established according to the depth of the working area under the standard axle load, the fitting parameters and the axle load:

[0039] H=H 100 +k(P-100) (1)

[0040] Among them, H is the depth of the subgrade working area; P is the axle load, which is obtained from the parameters when the vehicle leaves the factory; H 100 The depth of the working area when the standard axle load (axle load 100kN) can be determined by figure 2 The coordinate map query is obtained.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com