Ultrahigh-pressure industrial heat supply thermodynamic system

A thermal system and ultra-high pressure technology, applied in heating systems, steam central heating systems, household heating, etc., can solve problems such as poor economy, inability to meet the project's electrical load demand, and high environmental protection pressure to meet the electrical load and heat load demand, improve energy utilization efficiency, and achieve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

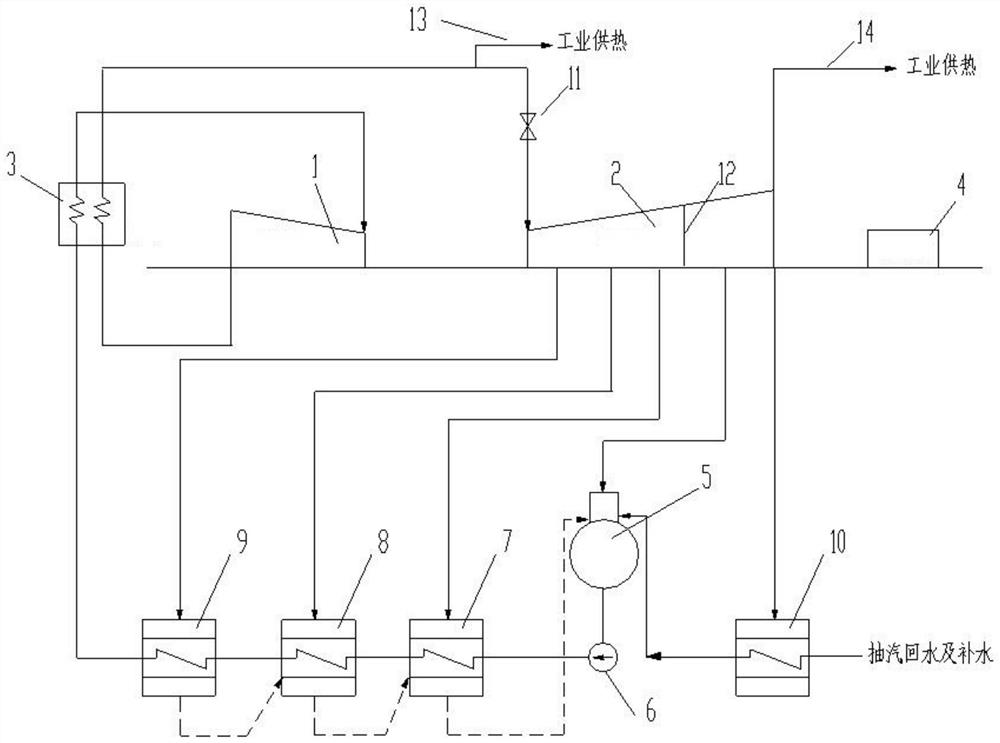

[0029] According to the design of the back-pressure unit mode, an ultra-high pressure industrial heating system includes a boiler 3, a high-pressure cylinder 1, a medium-pressure cylinder 2, a generator 4, and a medium-pressure steam inlet regulating valve 11; the high-pressure cylinder 1, medium Pressure cylinder 2 sub-cylinder pressure is designed as an ultra-high pressure parameter according to the industrial heating pressure; the medium pressure steam inlet regulating valve 11 is installed at the inlet of medium pressure cylinder 2, and the heating pressure is adjusted within a certain load range; An ultra-high pressure parameter heating pipe 13 is arranged between the boiler 3 and the medium-pressure steam inlet regulating valve 11 to realize external heat supply.

[0030] The outlet of the medium-pressure cylinder 2 is connected to the heat-supply pipe 14 for the exhaust of the medium-pressure cylinder.

[0031] The present invention optimizes the flow through the high-p...

Embodiment 2

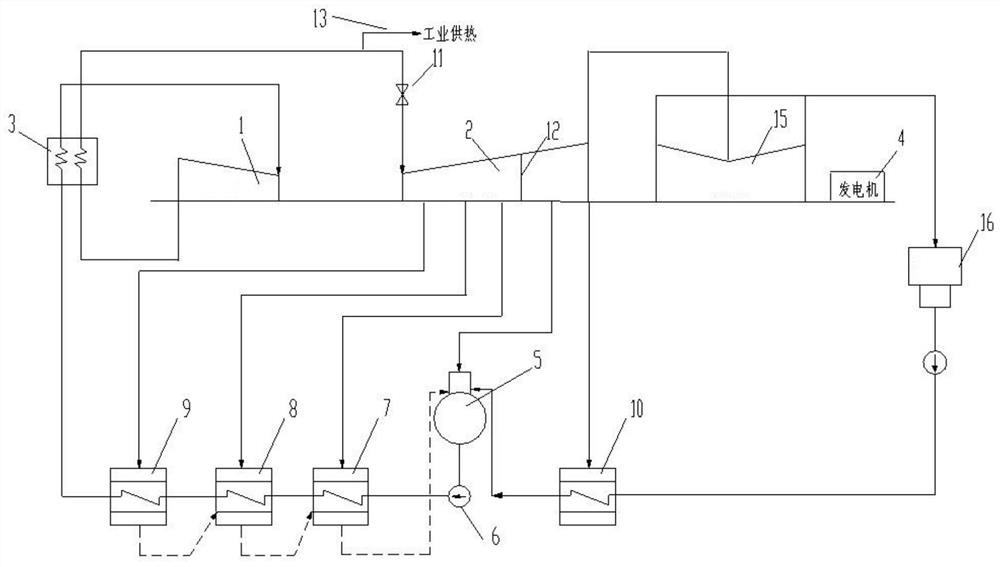

[0044] Such as figure 2 As shown, according to the model design of the condensing unit, an ultra-high pressure industrial heating system includes a boiler 3, a high-pressure cylinder 1 and a medium-pressure cylinder 2 respectively connected to the boiler 3, a generator 4, and a low-pressure cylinder 15; A medium-pressure steam inlet regulating valve 11 is installed at the entrance of the pressure cylinder 2; an ultra-high pressure parameter heating pipeline 13 is arranged between the boiler 3 and the medium-pressure steam inlet regulating valve 11. The steam turbine set described here is a condensing steam turbine set.

[0045] The present invention optimizes the flow through the high-pressure cylinder 1 and the medium-pressure cylinder 2, improves the ultra-high pressure parameter of the reheat pressure of the steam turbine unit, meets the requirements of the industrial heat load parameter for the ultra-high pressure parameter, and adjusts the medium-pressure steam inlet reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com