Acrylic laminate film, method for producing same, and deco sheet produced therefrom

A technology of laminating film and acrylic, applied in the field of acrylic laminating film and decorative sheet, it can solve the problems such as the limitation of increase in transmittance and smoothness of the film, and it is difficult to completely remove the whitening phenomenon, so as to achieve the improvement of optical properties and surface smoothness , The effect of preventing whitening and excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

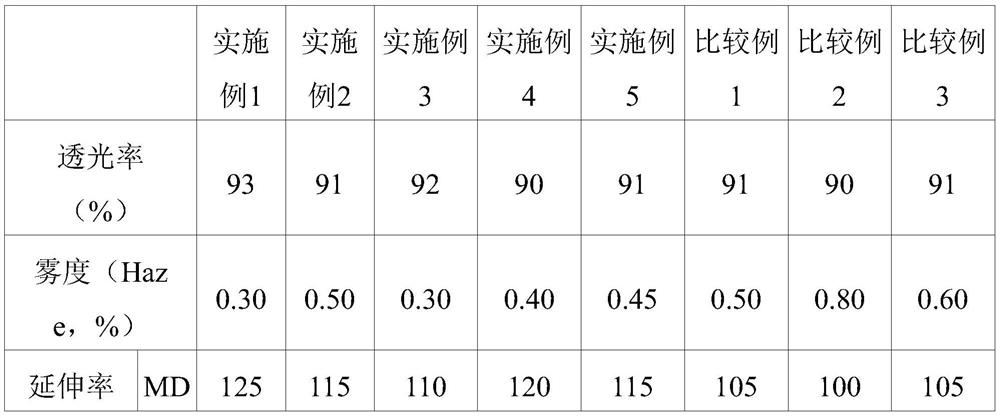

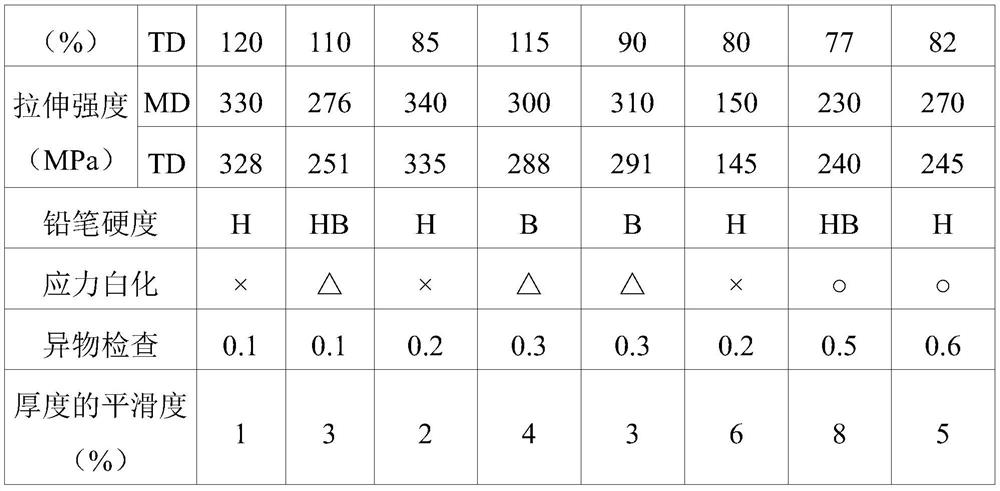

Examples

Embodiment 1

[0106] In order to form the inner layer by step 1, 250g of ion-exchanged water, 0.002g of ferrous sulfate, 0.008g of disodium ethylenediaminetetraacetic acid, 0.2g of sodium formaldehyde sulfoxylate and 2g of lauryl sulfate Sodium was added into a 5L reactor with a stirrer, and after replacing with nitrogen, the temperature was raised to 65°C.

[0107] After heating up, butyl acrylate of 35g, styrene of 5g, allyl methacrylate as grafting agent of 0.3g, 1,3-butanediol dimethacrylate as crosslinking agent of 1g, 0.2 g of sodium polyoxyethylene alkyl ether phosphate as an emulsifier, and 0.5 g of cumene hydroperoxide as an initiator were mixed and added dropwise over 2 hours. Stir at 200 rpm for 1 hour to carry out emulsion polymerization. The average particle size of the primary particle resin obtained at this time was 73 nm.

[0108] In order to form the intermediate layer through step 2, the primary granular resin and 0.1 g of sodium formaldehyde sulfoxylate were sequentiall...

Embodiment 2

[0113] The average size of the primary particle resin in the described embodiment 1 is prepared to be 171nm, the average size of the secondary particle resin is prepared to be 222nm, and the average particle size of the final acrylic copolymer resin is prepared to be 262nm. Proceed in the same manner as Example 1.

Embodiment 3

[0115] The average size of the primary particle resin in the described embodiment 1 is prepared to be 45nm, the average size of the secondary particle resin is prepared to be 140nm, and the average particle size of the final acrylic copolymer resin is prepared to be 239nm. Proceed in the same manner as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com