Processing and storing method of gynura procumbens leaf powder

A technique of storage method of chrysanthemum notoginseng and its storage method, which is applied in the field of processing and storage of chrysanthemum notoginseng leaf powder, and can solve the problem of large damage to the nutritional components of chrysanthemum notoginseng leaves and the active ingredients of chrysanthemum notoginseng leaves Problems such as excessive retention and low nutritional value of flat-lying chrysanthemum notoginseng leaf tea can achieve the effect of improving storage stability, avoiding mildew, and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

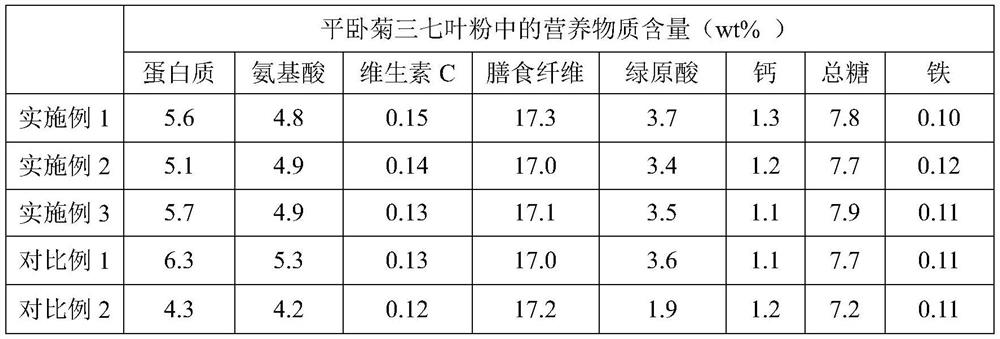

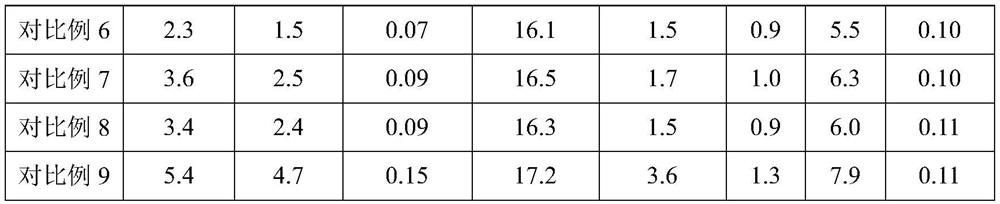

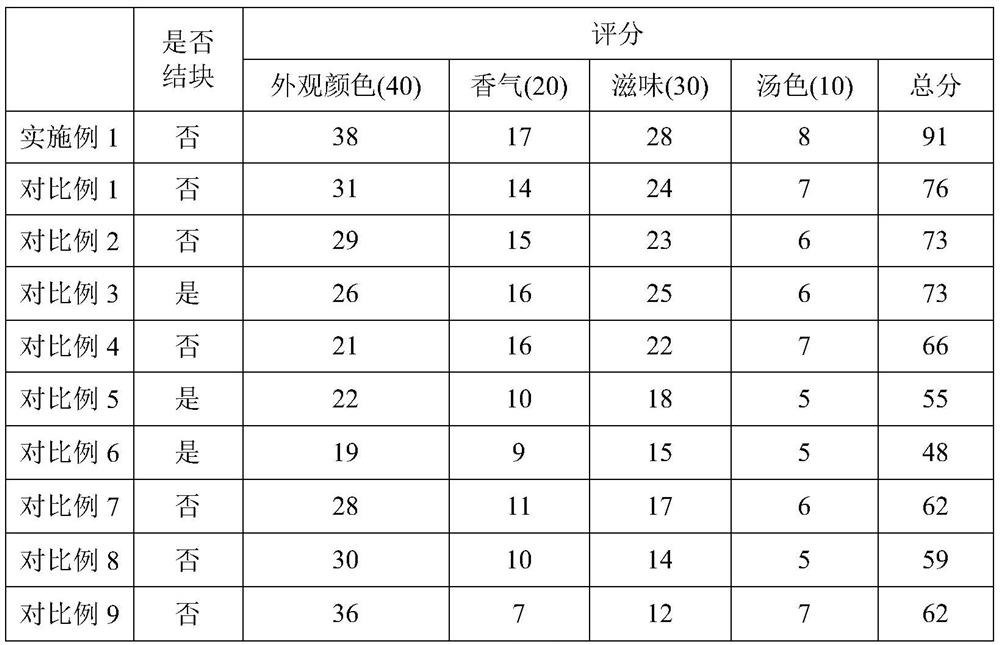

Examples

Embodiment 1

[0041] A method for processing and storing flat-lying chrysanthemum notoginseng leaf powder, comprising the steps of:

[0042] (1) Harvesting by machine for lying chrysanthemum notoginseng leaves: Use a two-person flat harvester to cut off the stems and leaves in sections, with a length of 10-20 cm;

[0043] (2) Green storage: the picked flat leaves of chrysanthemum notoginseng are stored in the chain-plate type silage machine, and the temperature of the silage is not higher than 25°C by blowing air;

[0044] (3) Steam de-enzyming: use a steam drum for de-enzyming, steam temperature 100°C, green leaf flow rate 110kg / h, cylinder speed 60 rpm, stirring shaft speed 300 rpm, de-enzyme time 9s;

[0045] (4) Cooling: the flat-lying chrysanthemum notoginseng leaves after finishing are quickly cooled by a leaf beater, the cooling time is 12 minutes, and the cooling degree: the finished leaves have no agglomeration and no water stains on the surface;

[0046] (5) kneading and drying: ...

Embodiment 2

[0058] A method for processing and storing flat-lying chrysanthemum notoginseng leaf powder, comprising the steps of:

[0059] (1) Harvesting by machine for lying chrysanthemum notoginseng leaves: Use a two-person flat harvester to cut off the stems and leaves in sections, with a length of 10-20 cm;

[0060] (2) Green storage: the picked flat leaves of chrysanthemum notoginseng are stored in the chain-plate type silage machine, and the temperature of the silage is not higher than 25°C by blowing air;

[0061] (3) Steam de-enzyming: use a steam drum for de-enzyming, steam temperature 100°C, leaf flow rate 100kg / h, cylinder speed 60 rpm, stirring shaft speed 500 rpm, de-enzyme time 8s;

[0062] (4) Cooling: the flat-lying chrysanthemum notoginseng leaves after finishing are quickly cooled by a leaf beater, and the cooling time is 10 minutes.

[0063] (5) kneading and drying: put the cooled flat chrysanthemum notoginseng leaves into a hot-air rough kneading machine at 90°C for 4...

Embodiment 3

[0075] A method for processing and storing flat-lying chrysanthemum notoginseng leaf powder, comprising the steps of:

[0076] (1) Harvesting by machine for lying chrysanthemum notoginseng leaves: Use a two-person flat harvester to cut off the stems and leaves in sections, with a length of 10-20 cm;

[0077] (2) Green storage: the picked flat leaves of chrysanthemum notoginseng are stored in the chain-plate type silage machine, and the temperature of the silage is not higher than 25°C by blowing air;

[0078] (3) Steam de-enzyming: de-enzyming with a steam drum, steam temperature 100°C, flow rate of green leaves 120kg / h, cylinder speed 80 rpm, stirring shaft speed 300 rpm, de-enzyme time 10s;

[0079] (4) Cooling: the flat lying chrysanthemum notoginseng leaves after finishing are quickly cooled by a leaf beater, the cooling time is 15 minutes, and the cooling degree: the finished leaves have no agglomeration and no water stains on the surface;

[0080] (5) kneading and dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com