Membrane emulsification system and method with high efficiency and low energy consumption

A low-energy, high-efficiency technology, applied in the field of membrane emulsification, can solve problems such as non-conformance, achieve the effect of avoiding noise, simplifying equipment, and improving quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

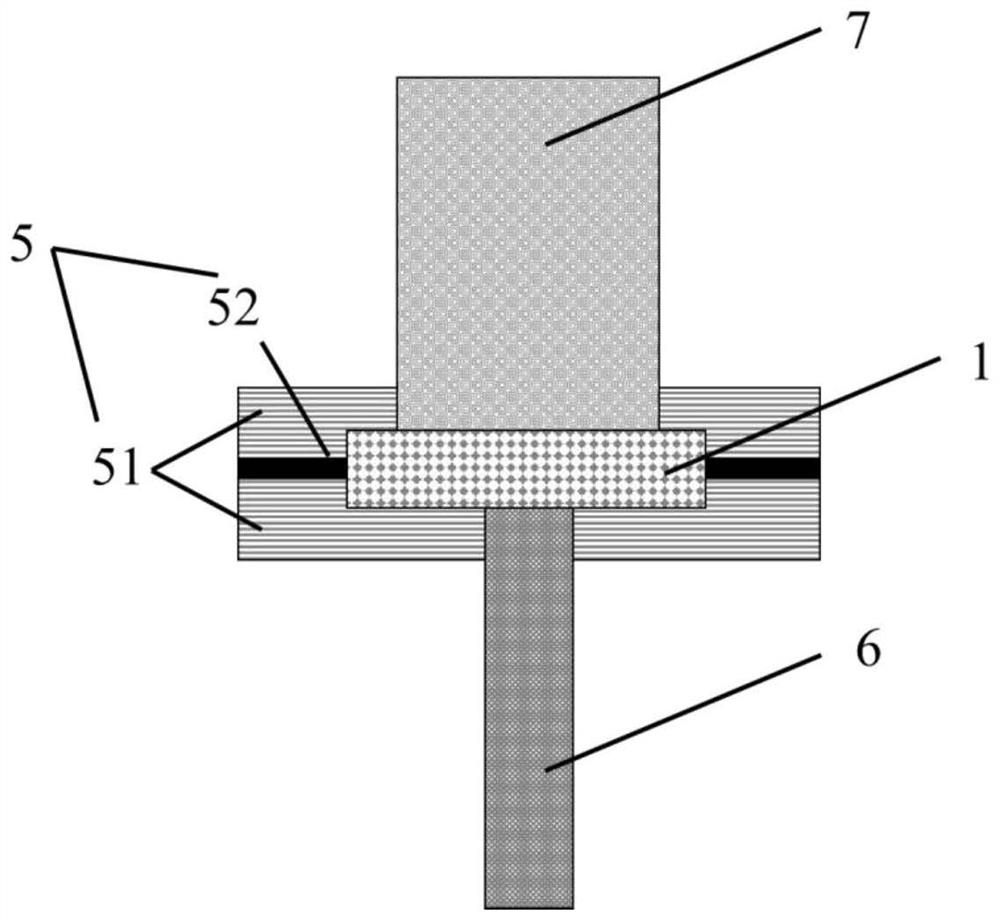

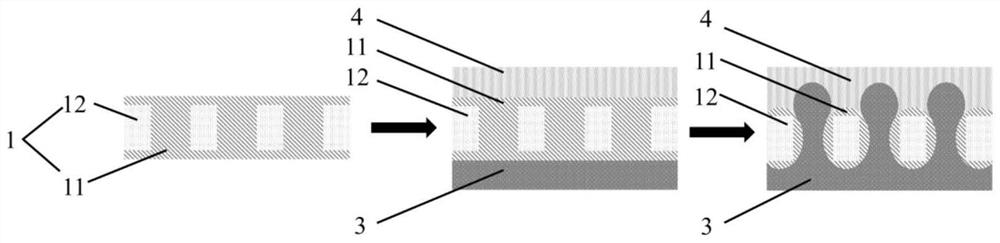

[0044] When using this emulsification system, follow the following rules: figure 1 The emulsification unit shown is based on this. The device of the present invention mainly includes a liquid-based porous membrane unit 1 , a main body 5 , a dispersed phase channel 6 and a continuous phase chamber 7 . The liquid-based porous membrane unit 1 includes a functional liquid 11 and a porous membrane 12 , and the functional liquid 11 at least partially infiltrates the porous membrane 12 . The main body 5 includes two clamping pieces 51 and a sealing material 52 , and the sealing material 52 cooperates with the part where the two clamping pieces 51 are connected to achieve a sealing effect. The liquid-based porous membrane unit 1 is located in the cavity, and the liquid-based porous membrane unit 2 is connected with the dispersed phase inlet channel 4 and the continuous phase chamber 3 .

[0045]The invention provides an emulsification method with high efficiency and low energy consu...

Embodiment 2

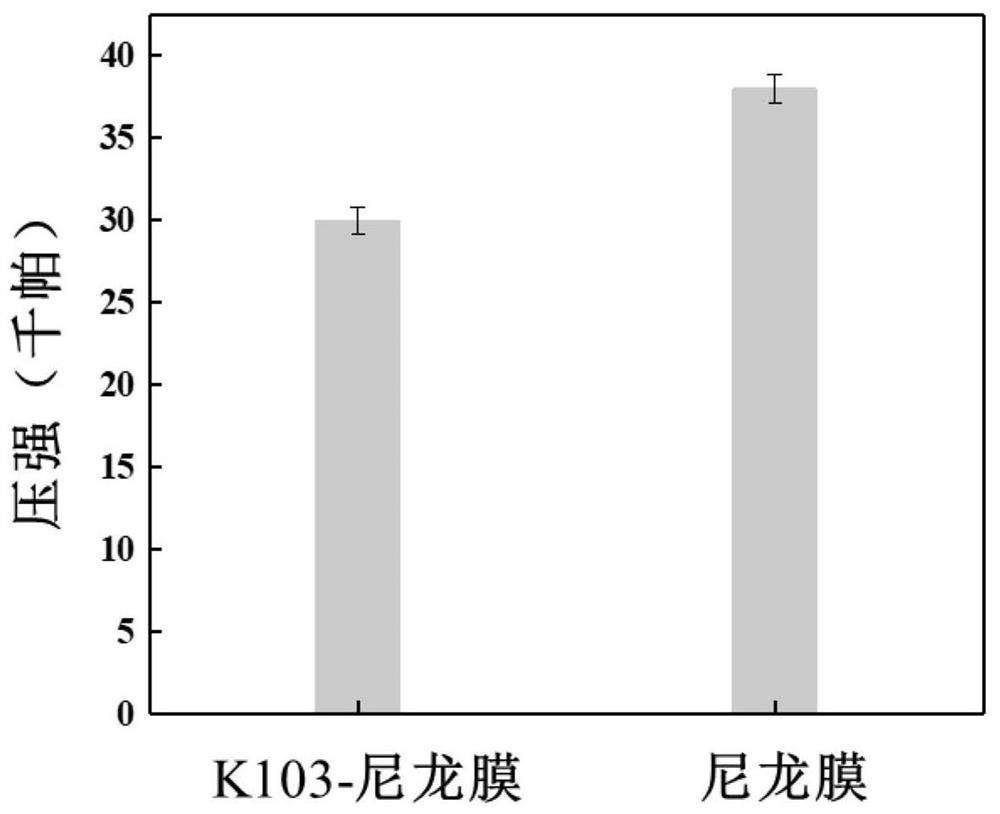

[0049] The invention discloses an emulsification method for preparing dodecane-water emulsion by anionic surfactant sodium lauryl sulfate. refer to figure 1 Based on the emulsification device shown, a nylon membrane (with a pore size of 1 μm) soaked in perfluoropolyether lubricating oil K103 was selected as the liquid-based porous membrane unit 1 . The selected concentration is 1×10 -3 The mol / L sodium lauryl sulfate aqueous solution is used as the continuous phase and is added in the continuous phase chamber 7. Dodecane was selected as the dispersed phase, passed through the dispersed phase channel 6 at a flow rate of 0.5 mL / min, and entered into the continuous phase chamber 7 to form an O / W emulsion. Such as image 3 As shown, the pressure threshold of the traditional nylon membrane is 38kPa, while the pressure threshold of the functional liquid infiltrated nylon membrane is 30kPa. Through calculation, 21% of the input energy can be saved, that is, the energy consumption ...

Embodiment 3

[0051] The invention discloses an emulsification method for preparing dodecane-water emulsion from nonionic surfactant glycolic acid ethoxy oil ether. refer to figure 1 Based on the emulsification device shown, a nylon membrane (with a pore size of 1 μm) soaked in perfluoropolyether lubricating oil K103 was selected as the liquid-based porous membrane unit 1 . The selected concentration is 0.5×10 -3 The mol / L glycolic acid ethoxy oleyl ether aqueous solution is used as the continuous phase and added to the continuous phase chamber 7. Dodecane was selected as the dispersed phase, passed through the dispersed phase channel 6 at a flow rate of 0.5 mL / min, and entered into the continuous phase chamber 7 to form an O / W emulsion. Such as Figure 4 As shown, both the traditional nylon membrane and the functional liquid soaked nylon membrane can form O / W type emulsion. The pressure threshold of the traditional nylon membrane is 58.4kPa, while the pressure threshold of the functiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com