SiF4 and HF mixed gas separation method and system

A technology of mixed gas and separation method, applied in the field of separation method and system of SiF4 and HF mixed gas, can solve the problems of air pollution, waste of resources, large energy consumption, etc., and achieve the effect of simple separation process and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

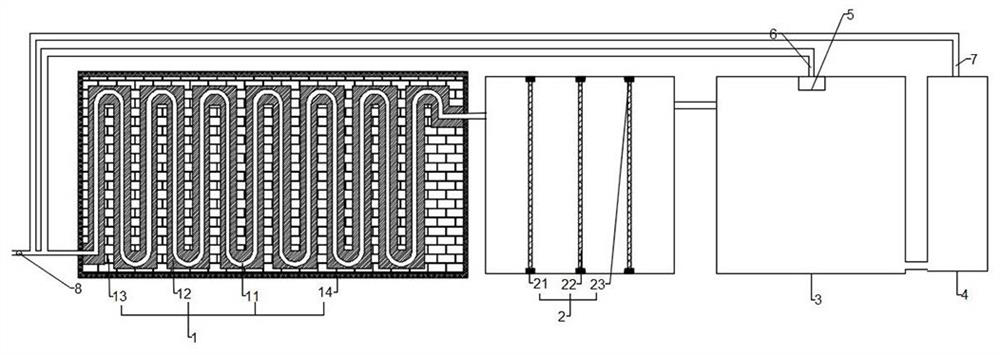

[0033] A method for separating SiF4 and HF mixed gas, relates to the above-mentioned gas separation system, and the method comprises the following steps:

[0034] S1, S1, pass the mixed gas of silicon tetrafluoride and hydrogen fluoride and hydrogen gas into the microwave heating device 1, the volume of the hydrogen gas is 4 times the volume of the mixed gas of silicon tetrafluoride and hydrogen fluoride, and the purity of the hydrogen gas is 99.9999%. The microwave heating device 1 rapidly heats the mixed gas of silicon tetrafluoride, hydrogen fluoride and hydrogen to 600°C;

[0035] S2, passing the mixed gas heated by the microwave heating device 1 and the silicon generated into the gas-solid separation device 2 for separation;

[0036] S3, passing the mixed gas separated by the gas-solid separation device 2 into the condenser 3 for condensation, the condensation temperature of the condenser 3 is -11°C, and the pressure is 0.6MPa;

[0037] S41: Pass the remaining gas conden...

Embodiment 2

[0042] A method for separating SiF4 and HF mixed gas, relates to the above-mentioned gas separation system, and the method comprises the following steps:

[0043] S1, S1, pass the mixed gas of silicon tetrafluoride and hydrogen fluoride and hydrogen gas into the microwave heating device 1, the volume of the hydrogen gas is 8 times the volume of the mixed gas of silicon tetrafluoride and hydrogen fluoride, and the purity of the hydrogen gas is 99.99999%. The microwave heating device 1 rapidly heats the mixed gas of silicon tetrafluoride, hydrogen fluoride and hydrogen to 1200°C;

[0044] S2, passing the mixed gas heated by the microwave heating device 1 and the silicon generated into the gas-solid separation device 2 for separation;

[0045] S3. Pass the mixed gas separated by the gas-solid separation device 2 into the condenser 3 for condensation, the condensation temperature of the condenser 3 is -13°C, and the pressure is 0.53MPa;

[0046] S41: Pass the remaining gas conden...

Embodiment 3

[0051] A method for separating SiF4 and HF mixed gas, relates to the above-mentioned gas separation system, and the method comprises the following steps:

[0052] S1. Pass the mixed gas of silicon tetrafluoride and hydrogen fluoride and hydrogen gas into the microwave heating device 1, the volume of the hydrogen gas is 5 times the volume of the mixed gas of silicon tetrafluoride and hydrogen fluoride, and the purity of the hydrogen gas is 99.99999%. The microwave heating device 1 rapidly heats the mixed gas of silicon tetrafluoride, hydrogen fluoride and hydrogen to 600°C;

[0053] S2, passing the mixed gas heated by the microwave heating device 1 and the silicon generated into the gas-solid separation device 2 for separation;

[0054] S3, passing the mixed gas separated by the gas-solid separation device 2 into the condenser 3 for condensation, the condensation temperature of the condenser 3 is -13°C, and the pressure is 0.6MPa;

[0055] S41: Pass the remaining gas condensed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com