Preparation method of epoxy chloropropane

A technology of epichlorohydrin and chlorinated liquid, which is applied in the direction of organic chemistry, can solve the problems of high requirements for process equipment, complex synthesis process, and large amount of three wastes, and achieve the advantages of small usage, high output, and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

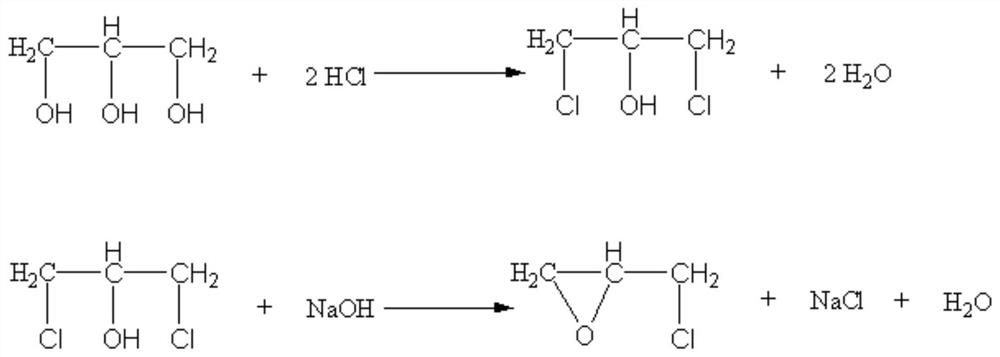

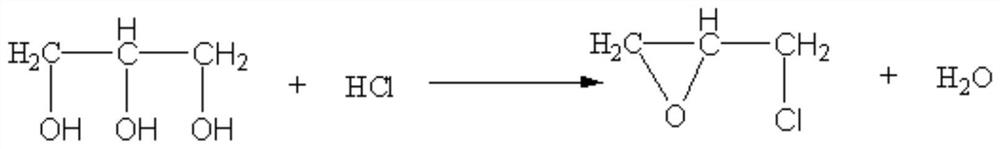

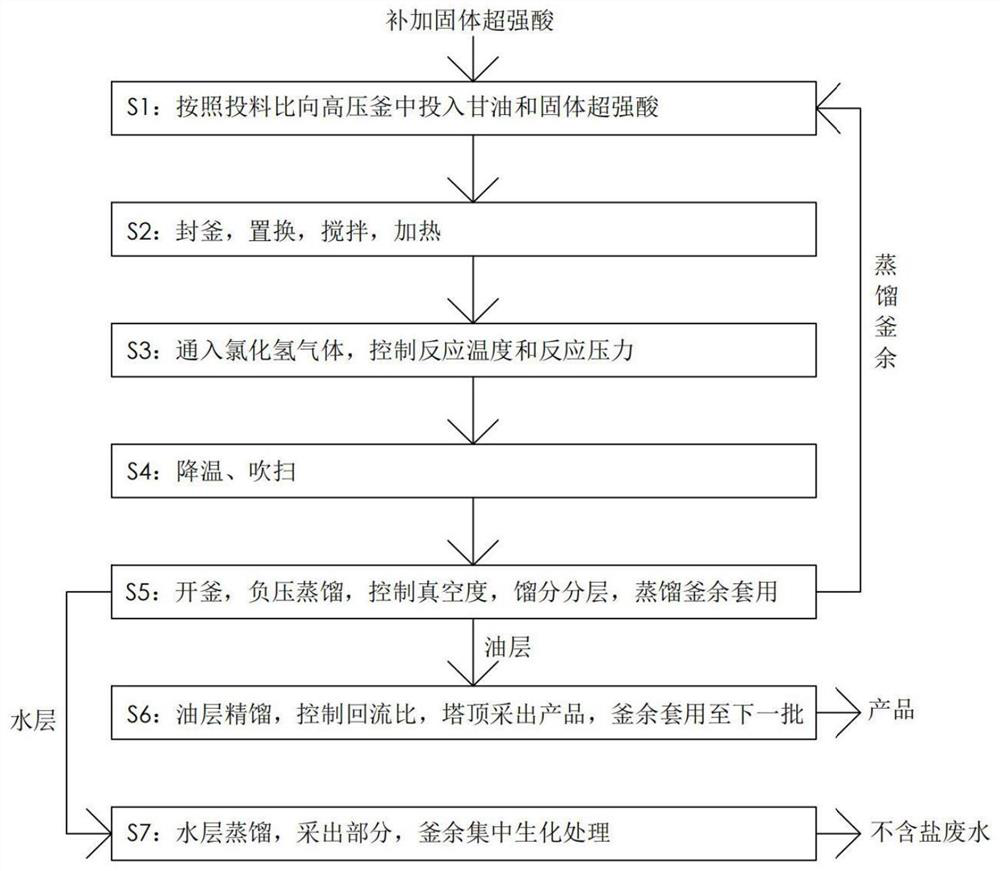

Method used

Image

Examples

Embodiment 1

[0032] Put SO4 into the autoclave 2- / TIO 2 Type solid superacid 3.75g and glycerin 750g (feeding coefficient 0.6), with N 2 Replace the air in the autoclave, stir, heat, control the reaction temperature at 170°C, pass hydrogen chloride gas into the autoclave through the gas cylinder, remove the heat of reaction through cooling water, maintain the reaction temperature, and keep the reaction pressure at 2.5MPa, and the reaction time is 15 minutes , to obtain chlorinated solution; after the reaction is completed, cool down to normal temperature, and use N 2 Bubble and purge the chlorinated liquid to remove the excess hydrogen chloride gas in the kettle to the water absorption system; open the kettle, put the chlorinated liquid into the crude distillation device, carry out negative pressure distillation, and control the vacuum degree to -0.085MPa~-0.1MPa, Control the temperature of the kettle not to exceed 100°C, pour the crude fraction into the separatory funnel for stratifica...

Embodiment 1~2

[0035] In order to investigate the impact of different solid superacids on the reaction, different types of solid superacids and mixed solid superacids were used in the reaction to carry out experiments, and all the other conditions were constant. The data are shown in Table 1:

[0036] Table 1

[0037] Example catalyst Product content (%) Yield (%) 1 SO4 2- / TIO 2 type solid superacid

[0038] As can be seen from Table 1, compared with the blank experiment example 2, the solid superacid has a catalytic effect on this reaction, and can greatly improve the product content and yield.

Embodiment 3~8

[0040] In order to investigate the impact of the ratio of solid superacid and glycerol on the reaction, with respect to Example 1, change SO4 2- / TIO 2 The consumption of type solid superacid is tested, and all the other conditions are constant, and data are as shown in table 2:

[0041] Table 2

[0042]

[0043] As can be seen from Table 2, solid superacid: glycerol=0.001~0.01, all have catalytic effect, wherein solid superacid: glycerol=0.002~0.008 effect is better, solid superacid: glycerol=0.003~0.006 effect is particularly good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com