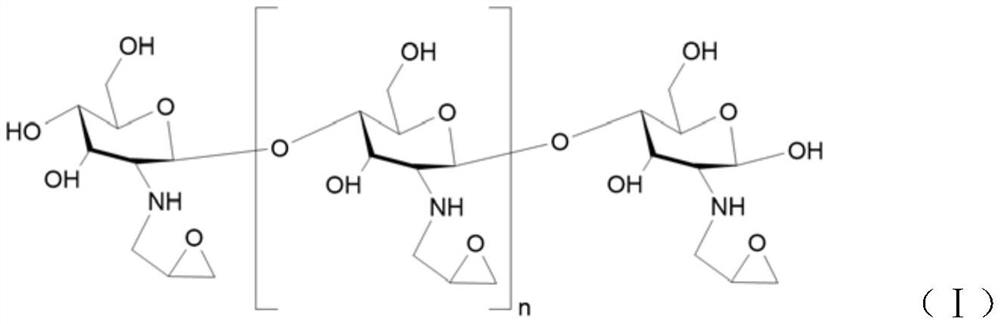

Fur tanning method based on bio-based epoxy active tanning agent

A bio-based, tanning technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, chemical treatment before tanning, etc. It can solve the problems of formaldehyde residue and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the method of the present invention is used to tan Tan sheepskin. The raw material skin used is salt-dried Tan sheep second fur. According to the size of the skin and the quality of the wool, the batches are carried out based on the principle that the size of the skin and the quality of the wool are similar. After tanning, because the wool fiber of the raw hide is long and spike-shaped, in order to prevent the wool from knotting during the tanning process, the liquid coefficient in the processing process is relatively large, usually controlled at about 18L / sheet. Specific steps are as follows:

[0045] (1) Soften

[0046] The raw skins are soaked in water, fleshed and degreased according to the conventional process.

[0047] Add water and sodium chloride to the groove, stroke the groove for 10 minutes, add formic acid to adjust the pH value to 3.5 after the sodium chloride is dissolved, add Angellzym HA protease (Tianjin Triumph, enzyme activity 200...

Embodiment 2

[0058] In this embodiment, sheep sheared fur is tanned by the method of the present invention, and the raw material skin used is salted Merino sheep skin, which is dry sheared. Adult Merino sheepskins are relatively large, so they are sheared before processing, so wet processing is not prone to napping problems, and tanning can be carried out in drums or slots, and the liquid coefficient is usually controlled at about 20L / sheet when tanning in slots . Specific steps are as follows:

[0059] (1) Soften

[0060] The raw skins are soaked in water, fleshed and degreased according to the conventional process.

[0061] Add water and sodium chloride to the groove, stroke the groove for 10 minutes, add formic acid to adjust the pH value to 3.5 after the sodium chloride is dissolved, then add 537 acid protease (enzyme activity is 2000~3000U / L), stroke The softening solution was formed in the tank for 30 minutes. In the softening solution, the concentration of sodium chloride was 45g...

Embodiment 3

[0072] In this embodiment, sheep sheared fur is tanned by the method of the present invention, and the raw material skin used is salted Merino sheep skin, which is dry sheared. Adult Merino sheepskins are relatively large, so they are sheared before processing, so wet processing is not prone to napping problems, and tanning can be carried out in drums or slots, and the liquid coefficient is usually controlled at about 20L / sheet when tanning in slots . Specific steps are as follows:

[0073] (1) Soften

[0074] The raw skins are soaked in water, fleshed and degreased according to the conventional process.

[0075] Add water and sodium chloride to the groove, stroke the groove for 10 minutes, add formic acid to adjust the pH value to about 7.0 after the sodium chloride is dissolved, then add DOWELLZYM OS protease (enzyme activity is 1000-1200U / L), stroke The softening solution was formed in the tank for 30 minutes. In the softening solution, the concentration of sodium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com