Aluminum alloy material, aluminum alloy wire and preparation method of aluminum alloy wire

A technology of aluminum alloy materials and aluminum alloy wires, applied in the field of conducting aluminum alloys, can solve problems such as long time, difficulty, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Secondly, the present application provides a method for preparing an aluminum alloy wire, which includes the following steps:

[0041] S1. According to the formula of the aluminum alloy wire, after the aluminum liquid is obtained, iron source, silicon source, zirconium source, lanthanum source, cerium source and yttrium source are added to the aluminum liquid for melting to obtain an aluminum alloy melt.

[0042] Among them, the way to obtain the aluminum liquid can be obtained by first obtaining aluminum ingots, and then melting the aluminum ingots. In order to avoid the introduction of impurities, the aluminum ingots can be aluminum ingots with a purity of not less than 99.7%. In addition, the way to obtain liquid aluminum can also be to directly use electrolytic aluminum liquid.

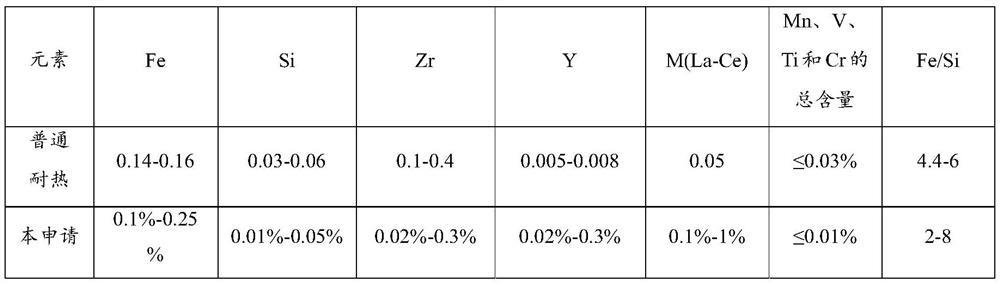

[0043] Wherein, by mass percentage, the formula includes the following ingredients:

[0044] Fe 0.1%-0.25%, Si 0.01%-0.05%, Zr 0.02%-0.3%, M 0.1%-1%, Y0.02%-0.3%, the total content of Mn, ...

Embodiment 1

[0067] An aluminum alloy wire, which is prepared by the following preparation method:

[0068] (1) Prepare raw materials according to Example 1 in Table 1: master alloys as iron source, silicon source, zirconium source, lanthanum source, cerium source and yttrium source, and an aluminum ingot with a purity of 99.7%.

[0069] (2) Melt the aluminum ingot with a purity of 99.7% in the holding furnace, and then accurately put in the rest of the raw materials for smelting, so that in the molten aluminum alloy obtained by smelting, by mass percentage, Fe 0.166%, Si 0.023%, Zr 0.047 %, M0.112%, Y 0.044%, the total content of Mn, V, Ti and Cr is controlled at ≤0.01%, and the balance is Al; wherein, the mass ratio of Fe to Si is 7.2.

[0070] (3) Use powder spraying refining agent in the holding furnace to remove slag and degas, and purify the furnace.

[0071] (4) Sampling the aluminum alloy liquid in the holding furnace to verify that the content of each element is qualified.

[00...

Embodiment 2-5

[0081] The preparation methods of Examples 2-5 are similar to those of Example 1, the only difference being the parameters shown in Table 3. In Examples 1-5, M is 35% La and 65% Ce (mass percentage).

[0082] The parameter of table 3 embodiment 1-5

[0083]

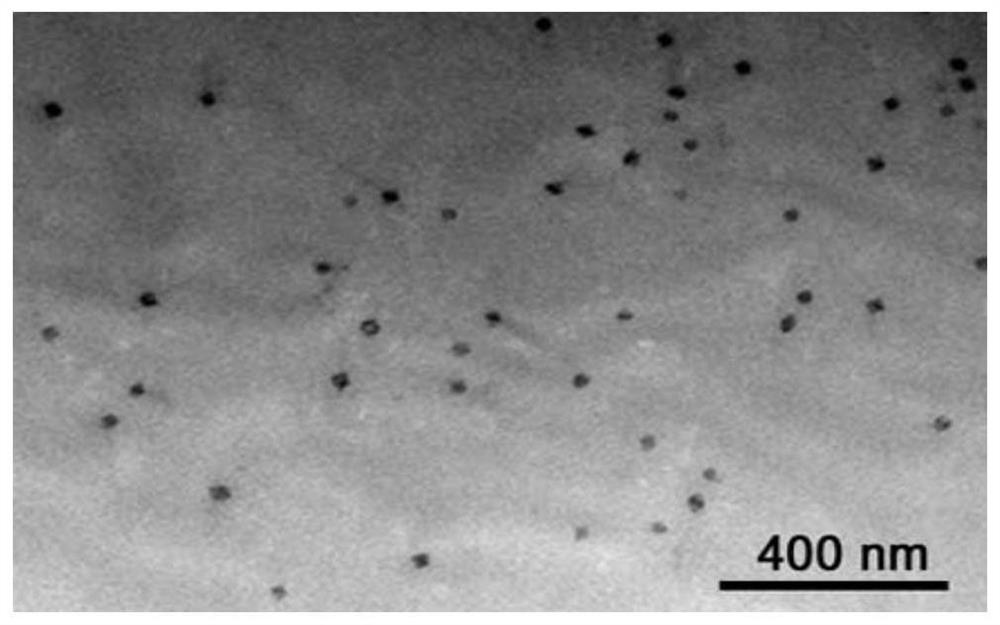

[0084] Wherein, the structure and composition of the wires of Examples 1-5 after heat treatment are similar to those of Example 1, which are α-Al matrix and dispersed and precipitated Al-Zr-Y heat-resistant phase.

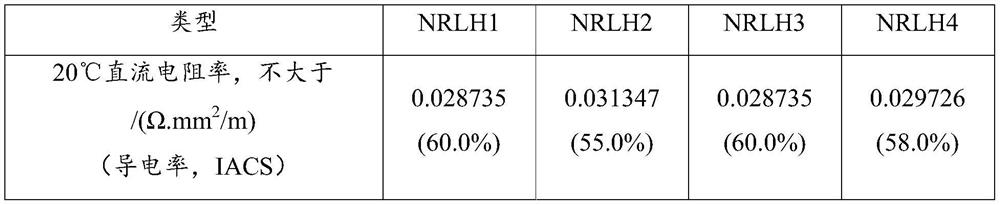

[0085] For the rods obtained in Examples 1-5 and the twisted single wires of the aluminum alloy conductors, the electrical conductivity and tensile strength were tested according to GB / T30551-2014, wherein the strength residual rate refers to the single wire heated at 230°C / 1h. The treatment method of silk is used to obtain the ratio of its strength retention rate to the initial measured value at room temperature (survival rate) to characterize its heat resistance.

[0086] The results are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com