Electromagnetic ejection underground hydraulic pulsation generating device and using method thereof

A technology of electromagnetic ejection and generating device, which is applied to earth-moving drilling, wellbore/well components, and production fluids, etc. Small area, improved pore sweep rate and recovery factor, and the effect of expanding sweep range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

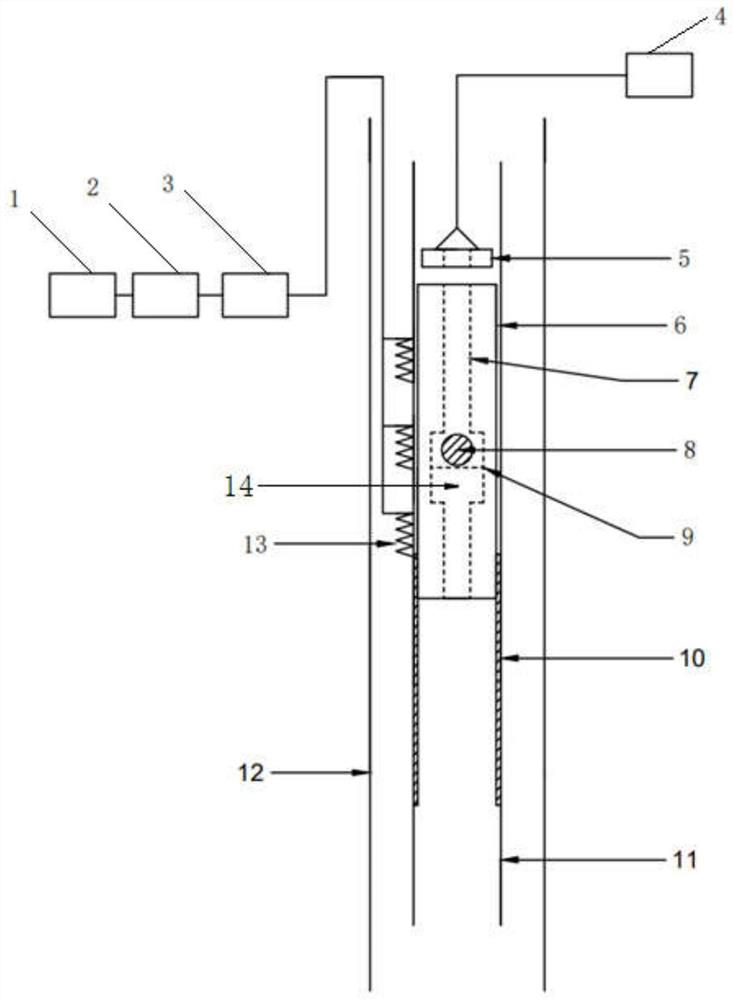

[0035] Such as Figure 1-4 As shown, this embodiment provides an electromagnetic catapult downhole hydraulic pulsation generating device, including a ground energy supply system, a lifting system, an electromagnet 5, an catapult system, an oil pipe 11, a plunger pump barrel 10 and an acceleration coil 13, wherein,

[0036] The ground is provided with a lifting system, the lifting system is connected with an electromagnet 5, the electromagnet 5 is arranged in the oil pipe 11, and the oil pipe 11 below the electromagnet 5 is provided with a plunger pump barrel 10, and the plunger pump barrel 10 is equipped with an ejector. system, the outside of the oil pipe 11 above the plunger pump barrel 10 is provided with an acceleration coil 13, and the acceleration coil 13 is connected to a ground energy supply system. The acceleration coil uses copper core PVC insulated wire, the wire core diameter is 2mm, the insulation thickness is 1mm, and the calculated outer diameter is 4mm.

[003...

Embodiment 2

[0056] An electromagnetic catapult downhole hydraulic pulsation generating device, the structure of which is as described in Embodiment 1, the difference is that a screen 9 is provided in the middle of the reaming cavity 14, and the movement range of the ball valve is narrowed by the screen to improve the sealing effect of the ball valve.

[0057] This embodiment is applied to oil layers with a well depth of 4700m, a reservoir pressure of 50MPa, and a fracture pressure of 90Mpa. The structural dimensions are designed as follows:

[0058] The length of the oil pipe is 30m, the outer diameter of the oil pipe is 88.9mm, the wall thickness is 6.45mm, and the inner diameter is 76mm;

[0059] The outer diameter of the electromagnet is 70mm, and the diameter of the through hole is 20mm;

[0060] The length of the ejection core is 15m, the outer diameter is 73mm, and the diameter of the cylindrical cavity is 20mm;

[0061] Reaming chamber length 40mm, diameter 30mm;

[0062] Ball va...

Embodiment 3

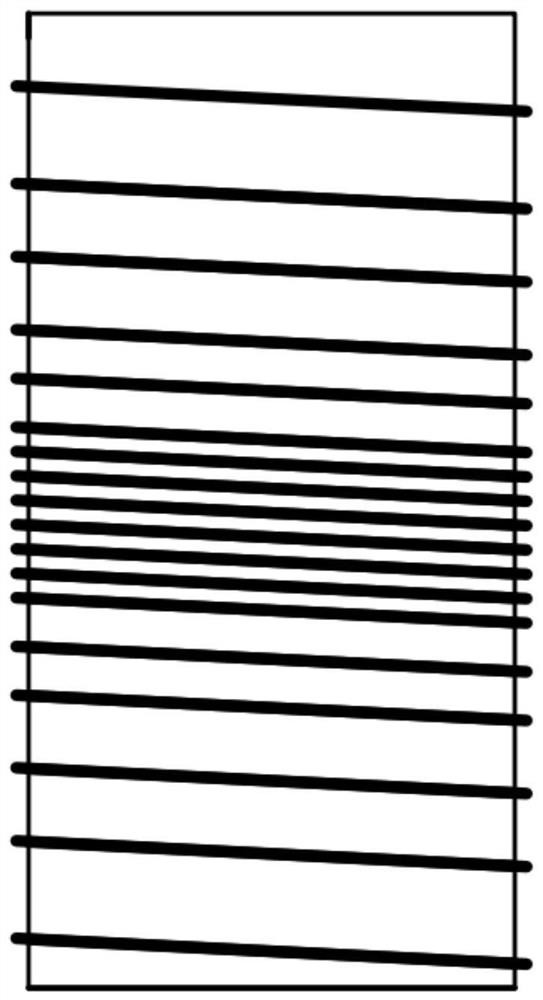

[0065] An electromagnetic ejection downhole hydraulic pulsation generating device, the structure is as described in Embodiment 1, the difference is that the acceleration coil 13 is arranged around the outside of the oil pipe 11, and the number of turns of the acceleration coil at the middle position is greater than the number of turns of the acceleration coil at both ends, so that the magnetic field As the gradient increases, the ejection force increases. The acceleration coil is provided with 3 sections to realize the multi-stage acceleration of the ejection system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com