Metal surface defect detection system based on machine vision

A defect detection and metal surface technology, applied in the direction of optical defect/defect test, instrument, measuring device, etc., can solve problems affecting processing quality, product performance, low efficiency, etc., to optimize image processing algorithms, facilitate integration and retention , the effect of high detection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

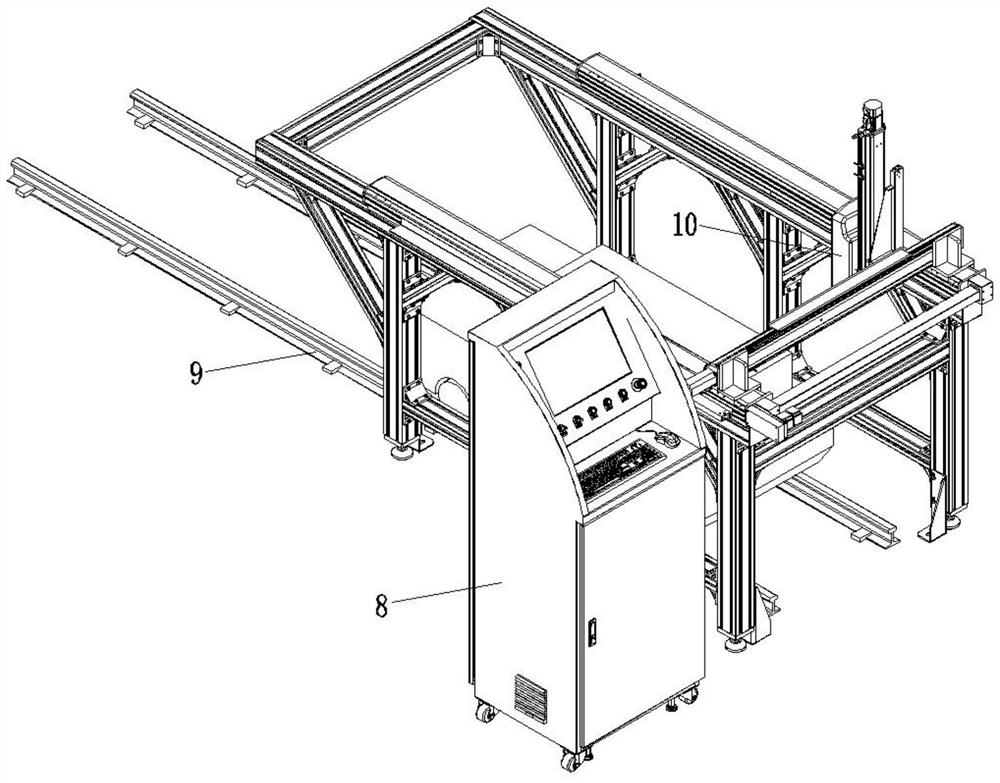

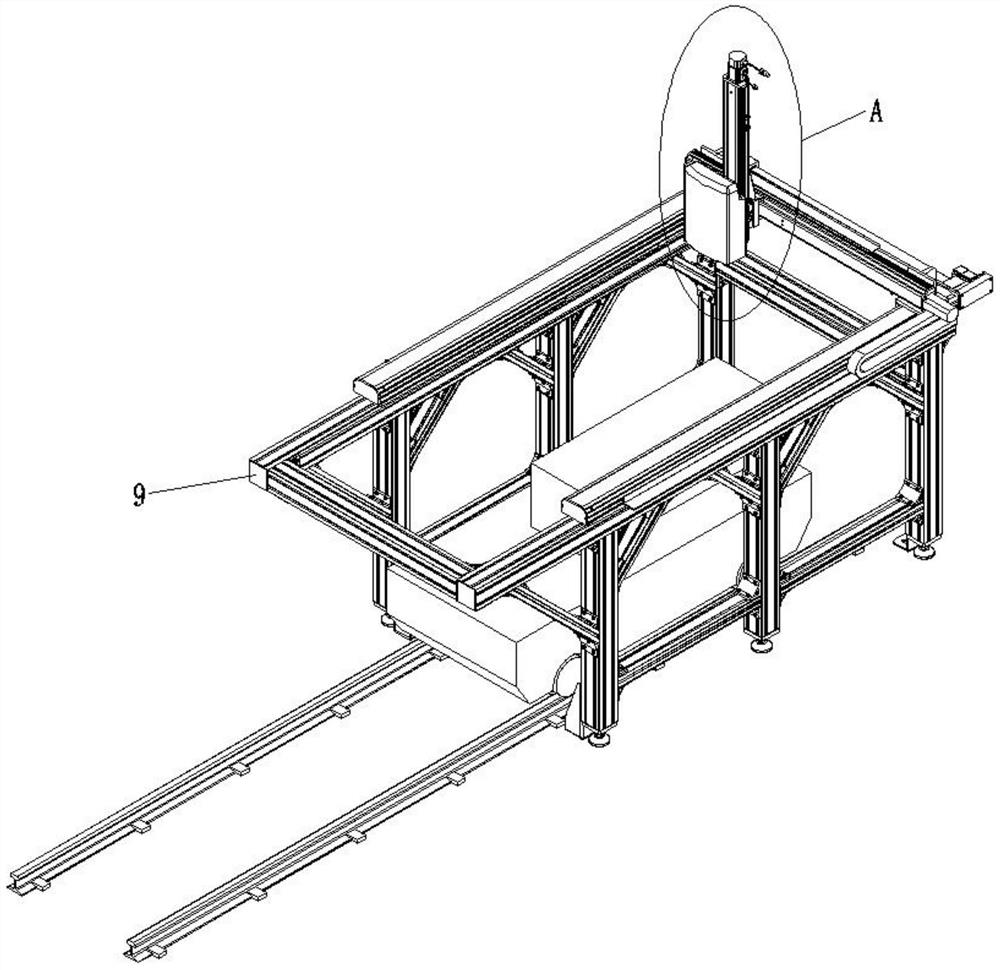

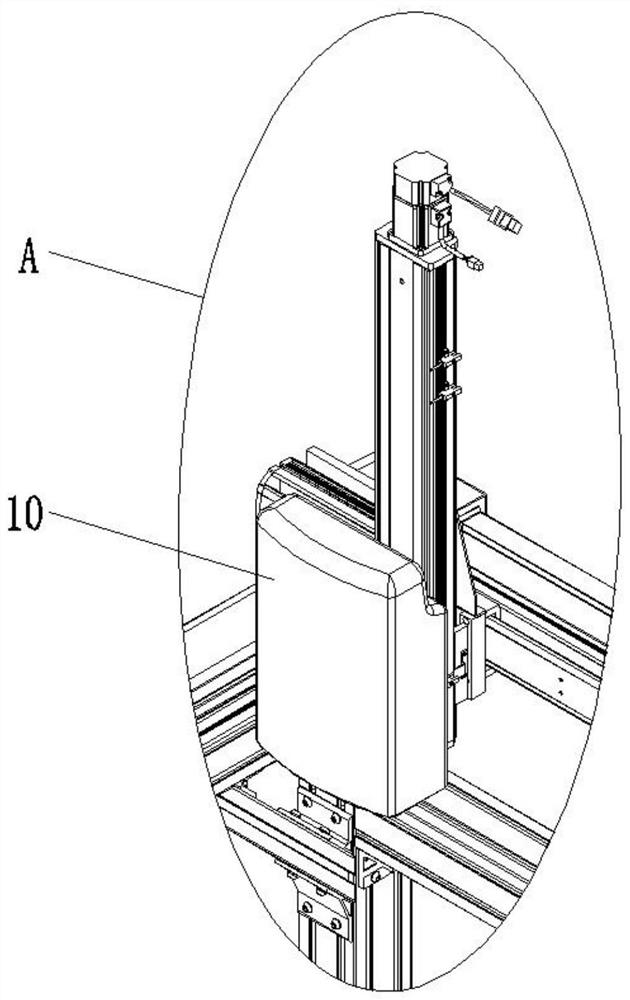

[0036] see Figure 1-3 , a metal surface defect detection system based on machine vision, including a motion control system, an optical imaging system, and an image processing system, and the motion control system, the optical imaging system, and the image processing system all communicate with the industrial computer 8 through respective corresponding communication protocols make a communication connection;

[0037] The motion control system includes a three-dimensional object loading platform 9, the three-dimensional object loading platform 9 adopts a gantry-type three-dimensional motion structure, and the motion control system is used for placing metal to detect defects on the metal surface;

[0038] see Figure 4-6 , the optical imaging system includes a base 1, the base 1 is arranged on the frame of the three-dimensional object loading platform, an area array industrial camera 2 and an optical lens 3 are installed on the surface of the base 1, the area array Two special...

Embodiment 2

[0051] Adopt a kind of metal surface defect detection system based on machine vision described in embodiment one to carry out test operation, such as Figure 7 As shown, the optical imaging system and the motion control system are connected to the industrial computer through the corresponding communication protocol. Its function is to image the surface features of the product on the camera sensor through the optical lens under the illumination of the light source, and convert the optical signal into an electrical signal, and then convert it to Complete the collection of product surface images for digital signals that can be recognized and processed by computers. The image processing system mainly involves image denoising, image enhancement and restoration, defect detection and comparison, and target segmentation for the collected images. Through the above method, the expression amount of the target feature can be described by extracting the image pixels, and the difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com