A kind of furan resin mixing and proportioning preparation system and preparation process

A technology of furan resin and preparation system, which is applied in the direction of mixers, sustainable manufacturing/processing, mixers with rotating stirring devices, etc., can solve the problems of insufficient power of main materials, difficulty in forming splashes, loss of power, etc., and achieve power Sufficient, strong jet sputtering effect, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

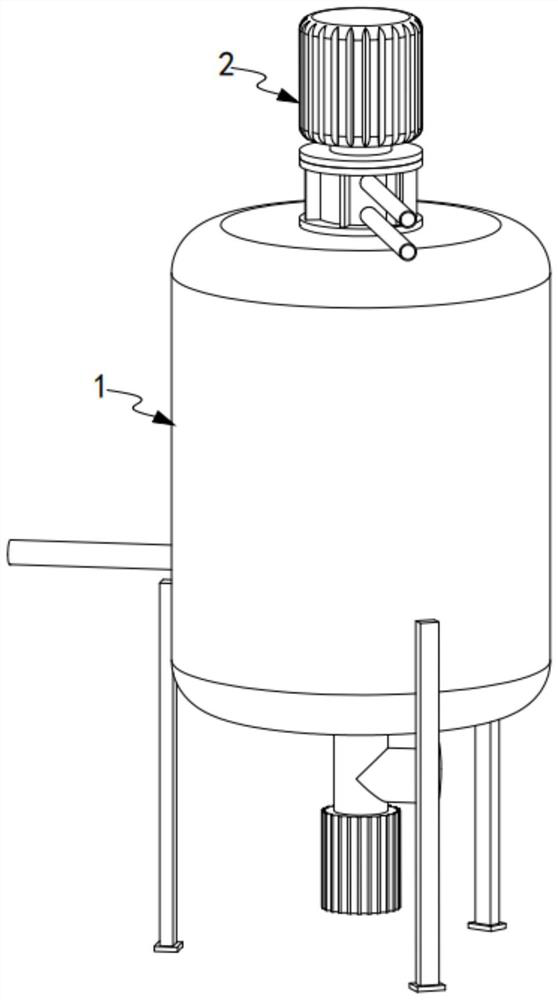

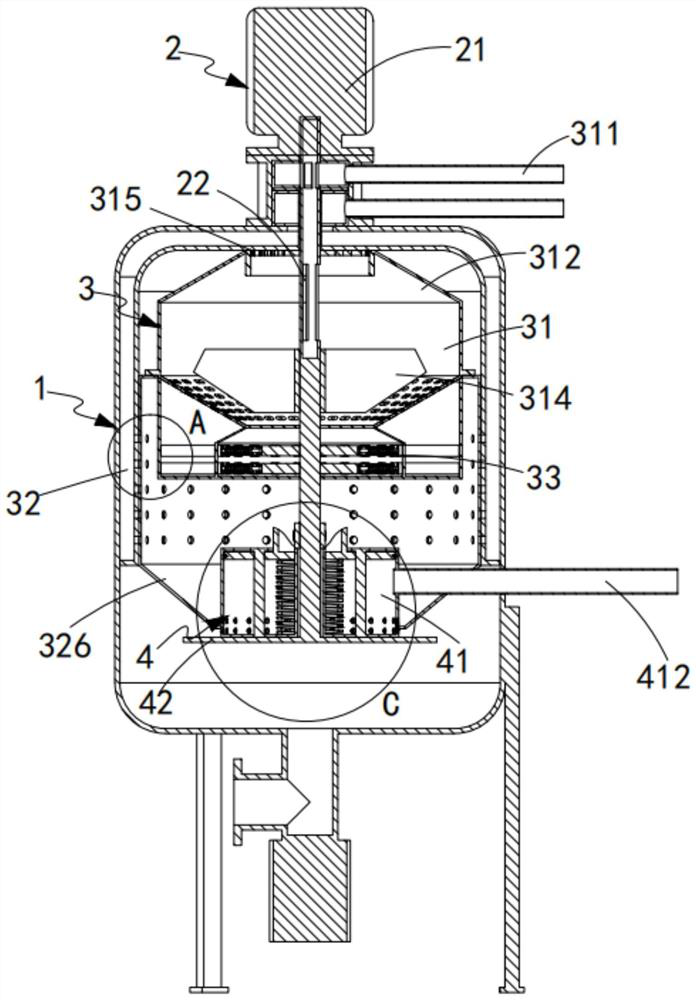

[0068] like Figure 1 to Figure 13 As shown, a furan resin mixing and proportioning preparation system includes a preparation tank 1 and a driver 2, and also includes:

[0069] The counter mixer 3 is arranged in the preparation tank 1. The counter mixer 3 includes a main material mixing mechanism 31, an auxiliary material diffuser mechanism 32 and a spray mechanism 33, and the main material mixing mechanism 31 is provided in the In the upper part of the preparation tank 1, the main material mixing mechanism 31 is located on the central axis of the preparation tank 1, the auxiliary material diffuser mechanism 32 is arranged around the main material mixing mechanism 31, and the auxiliary material diffuser mechanism 32 is located in the preparation tank. On the side wall of the tank 1, and the auxiliary material flow mechanism 32 outputs auxiliary materials to form a continuous liquid curtain 321, the injection mechanism 33 is arranged below the main material mixing mechanism 31,...

Embodiment 2

[0106] like Figure 14 As shown, a preparation process based on the furan resin mixing and proportioning preparation system of Embodiment 1, comprising:

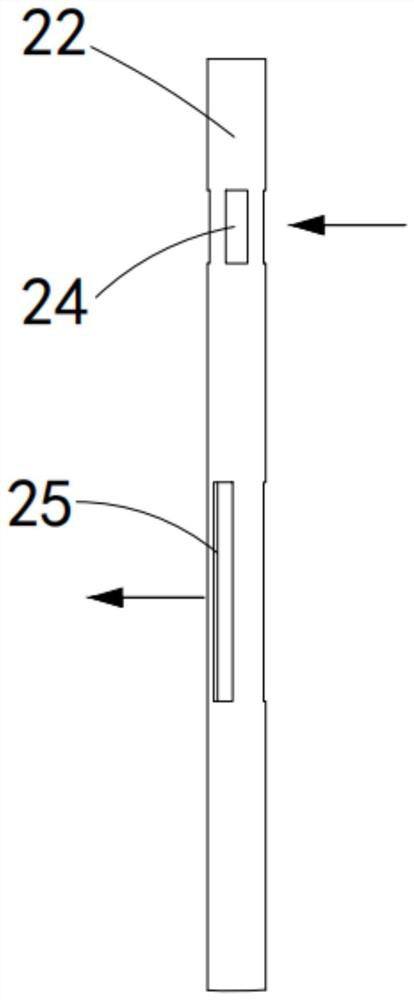

[0107] Step a, feeding, the main material enters the channel 23 of the main shaft 22 from the main feeding pipe 311 through the inlet 24, and then enters the main material bin 312 from the outlet 25, and the auxiliary material passes through the auxiliary feeding pipe 325 through the feeding port 323 Input into the auxiliary material bin 322, and the catalyst enters the compression bin 411 through the feeding pipeline 412;

[0108] Step b, the main material is stirred and sprayed, the main material entering the main material bin 312 is stirred by the stirring paddle 314 and then input into the material receiving bin 331, and after being sucked by the spray pipe group 332 driven by the rotation of the main shaft 22, it faces the auxiliary material. The direction of the bin 322 is sprayed to form the jet flow of the main mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com