Device and process for preparing methyl cyclopentane from cyclohexene

A technology of methylcyclopentane and methylcyclopentene, applied in the direction of hydrogenation hydrocarbon production, isomerization hydrocarbon production, catalysts, etc., can solve the problems of complex reaction products, long process flow, expensive catalysts, etc., and achieve the reaction route Simple, cost-effective, cheap and easy-to-get catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

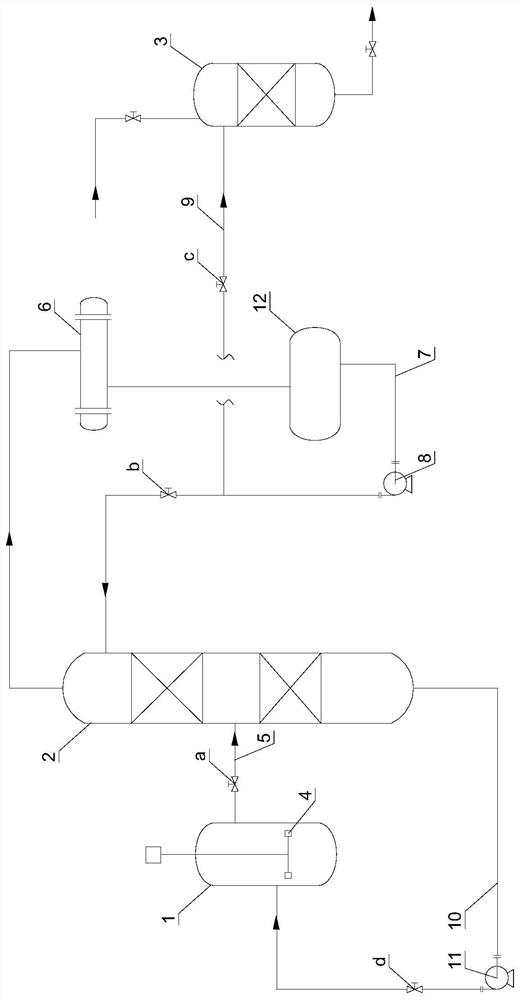

[0033] see figure 1The device for preparing methylcyclopentane from cyclohexene comprises a cyclohexene reactor 1, a rectifying tower 2, and a hydrogenation reactor 3. According to actual needs, the number of cyclohexene reactors is multiple, It is usually arranged in parallel, and the number of rectification towers can be set in multiples, which can be connected in parallel and / or in series. The number of hydrogenation reactors can also be set in multiples, usually in parallel. The agitator 4 is set in the cyclohexene reactor 1, and the feed inlet of the cyclohexene reactor 1 is used to link to each other with the cyclohexene source. In the present embodiment, the feed inlet of the cyclohexene reactor is arranged at the reaction The middle and lower part of the side wall of the device. The discharge port of the cyclohexene reactor 1 is connected to the rectification tower 2 through a discharge pipe 5, and the discharge pipe 5 is provided with a first valve a. In the present ...

Embodiment 2

[0035] Adopt the device of embodiment 1 to prepare methylcyclopentane, comprise the following steps:

[0036] 1) Get raw material cyclohexene (cyclohexene purity 99%wt), molecular sieve catalyst (control volume concentration 0.25), add in the cyclohexene reactor, the inner void volume of the cyclohexene reactor is 200m 3 , control the reaction temperature at 110-112°C, the pressure at 0.4-0.42MPa, and the cyclohexene feed flow at 100-105m 3 / h, molecular rearrangement occurs in cyclohexene to obtain a mixed material containing molecular sieve catalyst, cyclohexene, methylcyclopentene;

[0037] 2) The mixed material obtained in step 1) is discharged to the rectification tower, the top temperature of the rectification tower is controlled to be 35-37°C, the temperature of the tower bottom is 60-63°C, and the opening degree of the second valve and the third valve is controlled, After the separated methylcyclopentene is condensed into a liquid state by the condenser, it enters the...

Embodiment 3

[0041] Adopt the device of embodiment 1 to prepare methylcyclopentane, comprise the following steps:

[0042] 1) Get raw material cyclohexene (cyclohexene purity 99%wt), molecular sieve catalyst (control volume concentration 0.35), add in the cyclohexene reactor, the inner void volume of the cyclohexene reactor is 200m 3 , control the reaction temperature at 130-132°C, the pressure at 0.58-0.6MPa, and the cyclohexene feed flow at 180-183m 3 / h, molecular rearrangement occurs in cyclohexene to obtain a mixed material containing molecular sieve catalyst, cyclohexene, methylcyclopentene;

[0043] 2) The mixed material obtained in step 1) is discharged to the rectification tower, and the temperature at the top of the rectification tower is controlled to be 53-55° C., the temperature of the tower bottom is 79-81° C., and the opening degree of the second valve and the third valve is controlled. After the separated methylcyclopentene is condensed into a liquid state by the condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com