Method for regulating and controlling surface charges of polymer through infrared light

A surface charge and polymer technology, applied in the field of anti-friction and anti-wear, can solve the problems of increasing the amount of charge, unable to adjust freely, and the amount of charge cannot be restored to the initial value, etc., to reduce the sliding distance, prevent the occurrence of danger, and control methods. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

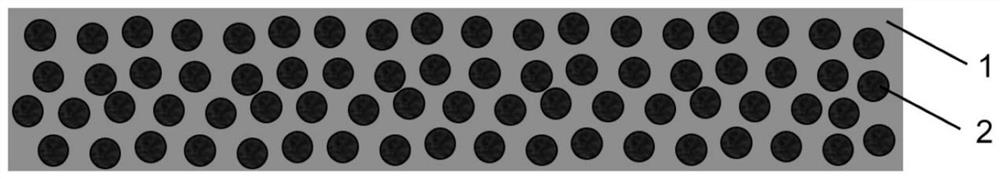

[0033] In the present invention, the preparation method of the polymer composite membrane preferably comprises the following steps:

[0034] The polymer, the light-to-heat conversion material and the curing agent are mixed, the obtained mixture is coated on the surface of the substrate, and the film is peeled off after drying to obtain the polymer composite film.

[0035] The present invention does not have special requirement to the kind of described curing agent, adopts the curing agent well-known to those skilled in the art to get final product, specifically can select corresponding commercially available curing agent according to the kind of polymer; The present invention does not have to the consumption of described curing agent For special requirements, the dosage well known to those skilled in the art can be used. In the present invention, the mixing method is preferably stirring and mixing, the rotational speed of the stirring and mixing is preferably 100-500 r / min, an...

Embodiment 1

[0048] Accurately weigh 10 parts of PDMS (Sylgard 184), 1 part of curing agent, 0.1 part of spherical Fe with a particle size of 5nm 3 o 4 In a beaker, stir mechanically at a speed of 200r / min for 1h to make it evenly mixed, scrape the mixed material evenly on a PET plastic plate with a scraper, dry it in an oven at 80°C for 2h, take it out, and peel off the film to obtain a polymer Composite film.

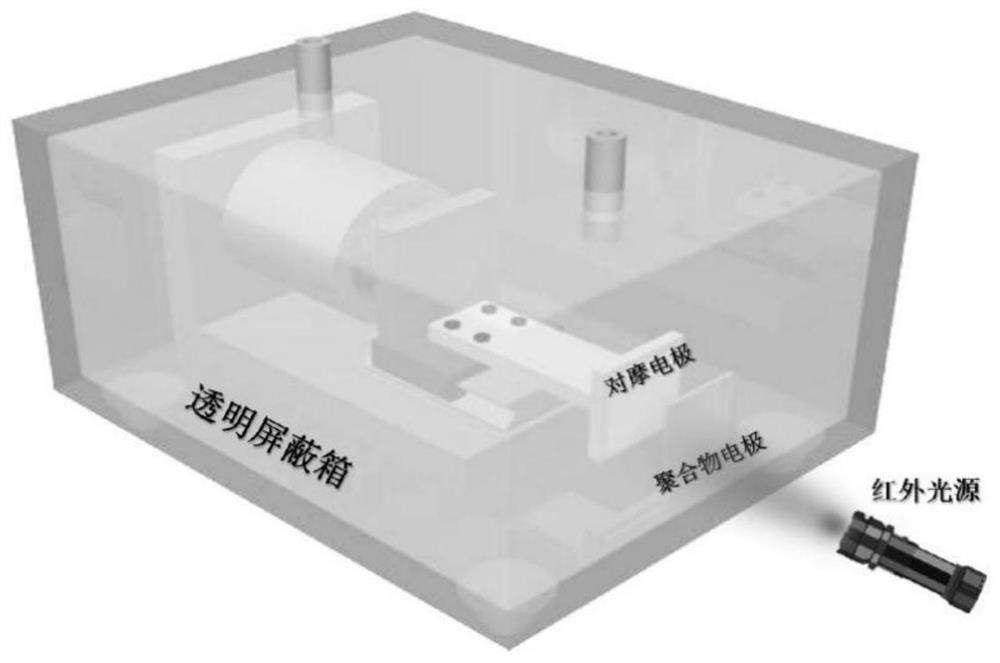

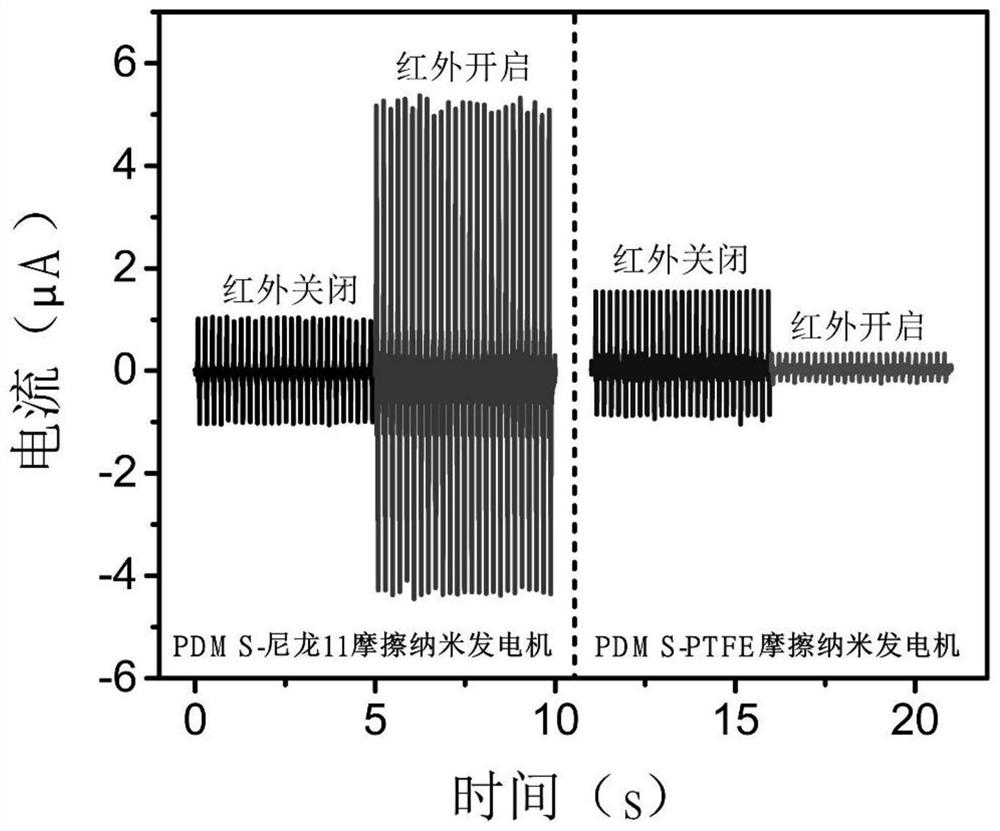

[0049] The polymer composite film was cut into a size of "4cm×4cm", and ITO / PEN electrodes were pasted on the back and leads were drawn out to obtain PDMS electrodes. At the same time, mix 2 parts of nylon 11 particles with 9 parts of anhydrous formic acid and 9 parts of dichloromethane and stir for 5 hours to dissolve them, and then spin coat them on copper tape at a speed of 2000 r / min on a spin coater and draw out copper wires. Dry at 60°C for 1 hour to obtain a nylon 11 electrode; cut the PTFE membrane into a size of "4cm×4cm", stick a copper electrode on the back and lead o...

Embodiment 2

[0053] Accurately weigh 10 parts of PDMS (Sylgard 184), 1 part of curing agent, 0.05 parts of spherical Fe with a particle size of 5nm 3 o 4 In a beaker, mechanically stir at a speed of 200r / min for 1 hour to make it evenly mixed. Use a spatula to evenly scrape it on a PET plastic plate, dry it in an oven at 80°C for 2 hours, take it out, and cut it into a size of "4cm×4cm". size of.

[0054] Put the composite film on the friction testing machine, use glass ball and PTFE ball as the friction pair (glass ball friction makes the surface of the composite film negatively charged, PTFE ball friction makes the surface of the composite film positively charged), test the two kinds of balls and PDMS composite film The coefficient of friction when rubbing. During the friction coefficient test, after the friction coefficient reached a stable level, the infrared light source was turned on to irradiate the friction surface between the ball and the PDMS composite film, and the change of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com