System and method for coproducing hydrogen and heat through water electrolysis on basis of integrated renewable energy sources

A renewable energy, water electrolysis technology, applied in the direction of renewable energy integration, energy industry, heating system, etc., can solve the problems of hydrogen production efficiency reduction, high cost, electrolyte temperature rise, etc., to save energy and improve energy The effect of utilization efficiency and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

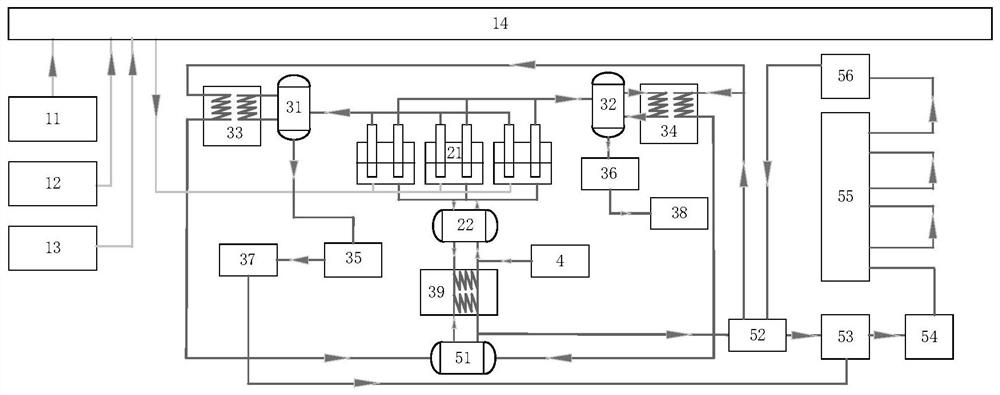

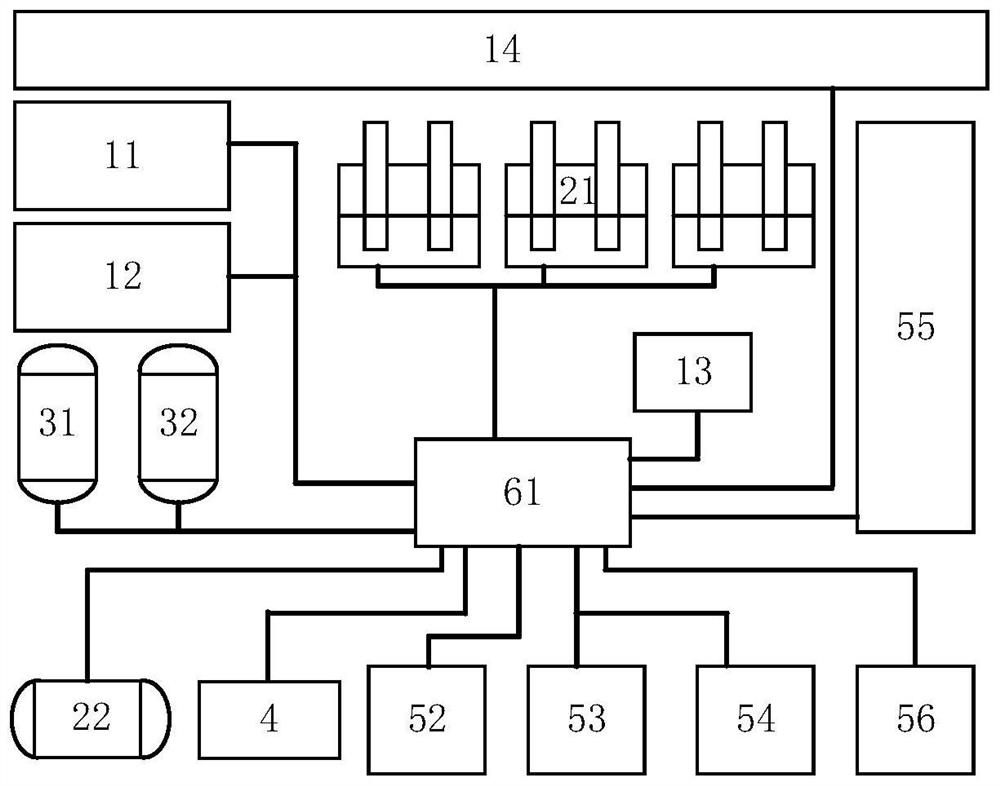

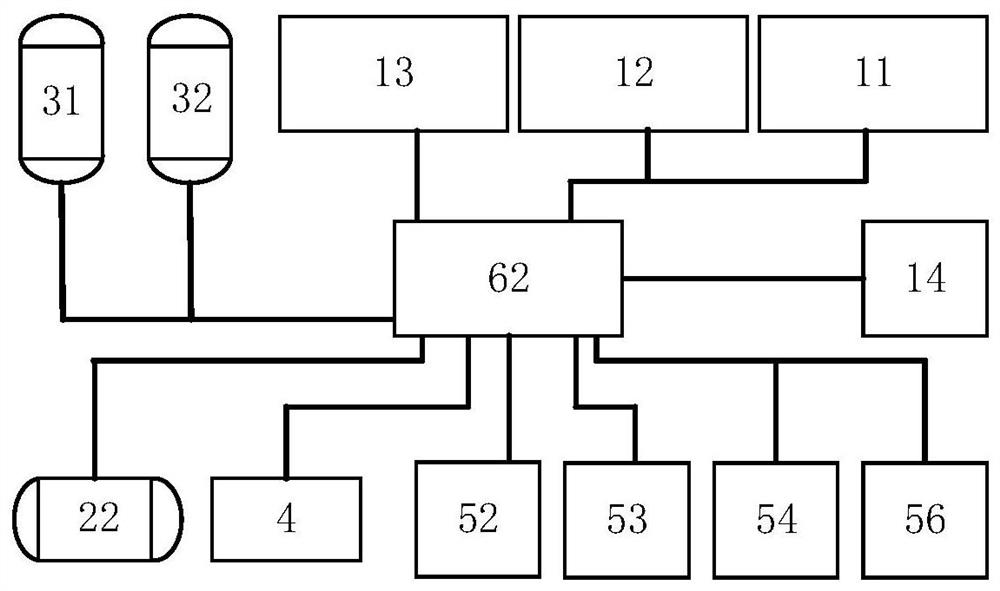

[0036] Such as figure 1 , the comprehensive renewable energy water electrolysis hydrogen heat cogeneration system of the present invention includes a renewable energy supply subsystem 1, a water electrolysis hydrogen production subsystem 2, a hydrogen production waste heat recovery and utilization subsystem 3, and a new electrolyte preheating subsystem 4. District heating heating network subsystem 5, monitoring and dispatching subsystem 6; renewable energy supply subsystem 1 includes wind turbine 11, photovoltaic power generation system 12, storage battery 13, and microgrid 14; water electrolysis hydrogen production subsystem 2 includes Electrolyzer 21, electrolyte collector 22; hydrogen production waste heat recovery and utilization subsystem 3 includes hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com