Preparation method of flexible carbon/lanthanum ferrite composite fiber membrane material

A technology of composite fiber membrane and lanthanum ferrite, which is applied in the direction of inorganic raw material artificial filaments, textiles, papermaking, non-woven fabrics, etc., can solve the problems of material microscopic appearance and property differences, and achieve uniform microscopic appearance and easy raw materials The effect of obtaining and preparation method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Add 0.60g Fe(NO 3 ) 3 9H 2 O, 0.62g La(NO 3 ) 3 ·6H 2 O. 0.5g of polyvinylpyrrolidone (PVP) with an average molecular weight of 1,300,000 was dissolved in 5mL of N,N-dimethylformamide (DMF), and magnetically stirred for 12h until fully dissolved to obtain LaFeO 3 precursor solution.

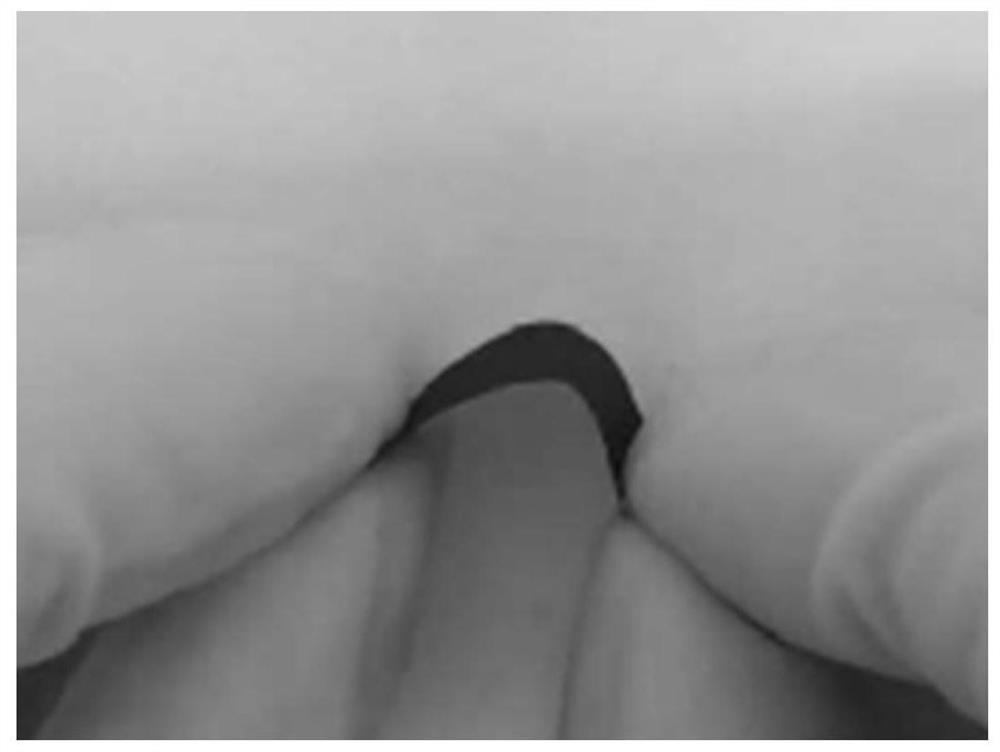

[0035] 2. Using the electrospinning method, the LaFeO 3 The precursor solution is electrospun and collected by a drum collector. The parameters of electrospinning are: needle 21G, electrospinning speed 0.3mL / h, electrospinning distance 15-20cm, working voltage 12-15kV; Drying at low temperature for 12 hours to remove residual DMF to obtain carbon / lanthanum ferrite composite precursor fiber membrane, and fix the fiber membrane with a glass plate to prevent curling deformation. The precursor fiber film has uniform film formation and uniform color.

[0036] 3. Put the carbon / lanthanum ferrite composite precursor fiber film in step 2 at a flow rate of 30mL / min N 2 In the atmosphere...

Embodiment 2

[0038] 1. Add 0.60g Fe(NO 3 ) 3 9H 2 O, 0.62g La(NO 3 ) 3 ·6H 2 O. 0.67g of PVP with an average molecular weight of 1,300,000 was dissolved in 5mL of DMF, and magnetically stirred for 12h until fully dissolved to obtain LaFeO 3 precursor solution.

[0039] 2. Using the electrospinning method, the LaFeO 3 The precursor solution is electrospun and collected by a drum collector. The parameters of electrospinning are: needle 21G, electrospinning speed 0.3mL / h, electrospinning distance 15-20cm, working voltage 12-15kV; Drying at low temperature for 12 hours to remove residual DMF to obtain carbon / lanthanum ferrite composite precursor fiber membrane, and fix the fiber membrane with a glass plate to prevent curling deformation.

[0040] 3. Put the carbon / lanthanum ferrite composite precursor fiber film in step 2 at a flow rate of 30mL / min N 2 In the atmosphere, first raise the temperature at 2°C / min to 300°C, keep the temperature for 1 hour, then raise the temperature at 2°C / ...

Embodiment 3

[0042] 1. Add 0.60g Fe(NO 3 ) 3 9H 2 O, 0.62g La(NO 3 ) 3 ·6H 2O. Dissolve 0.83g of PVP with an average molecular weight of 1,300,000 in 5mL of DMF, stir magnetically for 12h until fully dissolved, and obtain 0.3mmol / mL of LaFeO 3 precursor solution.

[0043] 2. Using the electrospinning method, the LaFeO 3 The precursor solution is electrospun and collected by a drum collector. The parameters of electrospinning are: needle 21G, electrospinning speed 0.3mL / h, electrospinning distance 15-20cm, working voltage 12-15kV; Drying at low temperature for 12 hours to remove residual DMF to obtain carbon / lanthanum ferrite composite precursor fiber membrane, and fix the fiber membrane with a glass plate to prevent curling deformation.

[0044] 3. Put the carbon / lanthanum ferrite composite precursor fiber film in step 2 at a flow rate of 30mL / min N 2 In the atmosphere, first raise the temperature at 2°C / min to 300°C, keep the temperature for 1 hour, then raise the temperature at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com