Supercritical boiler flexible peak shaving system and method

A supercritical boiler, flexible technology, applied in the direction of combustion method, steam generation method, boiler cleaning device, etc., can solve the problem of high load in the wet state, increase the temperature at the middle point, increase the steam consumption, and improve the combustion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

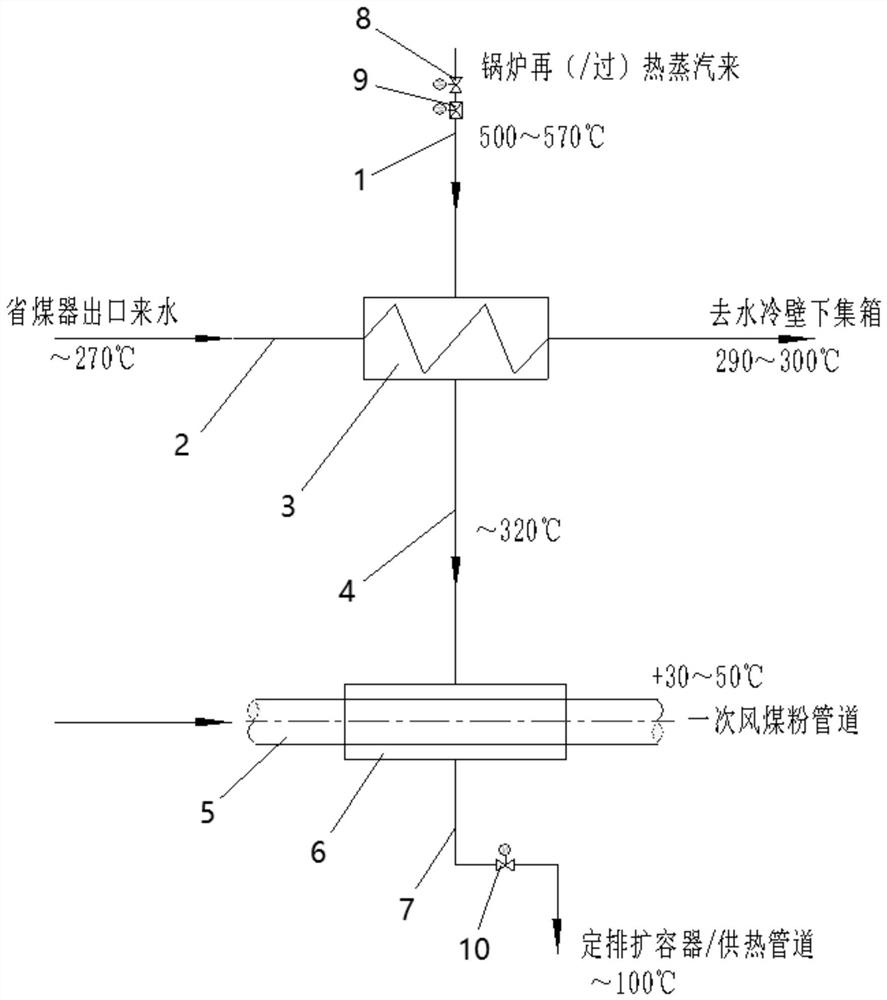

[0047] The flexible peak-shaving system of the supercritical boiler in this embodiment includes a reheating steam pipeline 1, a shell-and-tube steam-water heater, and an intermediate steam pipeline leading to the primary air pulverized coal pipeline 5 for surface heating after the steam temperature drops to about 300°C 4. Steam pulverized coal heater 6, exhaust steam pipeline 7, isolation shut-off door 8 of exhaust steam pipeline, exhaust steam shut-off gate 10 and steam volume adjustment gate 9;

[0048] The steam extraction position is the steam main pipe in the reheating hot section. The extraction steam pressure and temperature vary slightly with the boiler capacity parameters. Under low load, it is generally 2~3MPa, and the steam temperature is 500~570℃. The extracted reheated steam heats the boiler water at the outlet of the economizer through the shell-and-tube heat exchanger (i.e., the steam boiler water heater 3), so that the temperature of the boiler water in the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com