Coal-fired boiler flue gas decarburization device

A technology for coal-fired boilers and decarbonization, which is applied to combined devices, gas treatment, combustion methods, etc., can solve problems such as single-function reaction conversion and collection, and achieve the effect of easy operation and installation, and improved decarbonization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

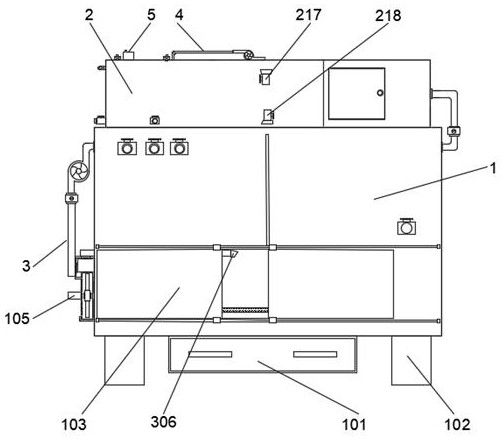

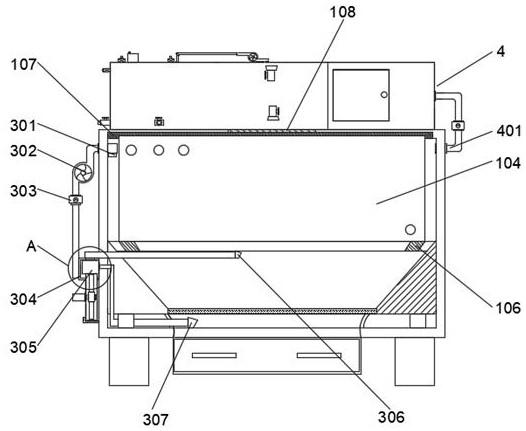

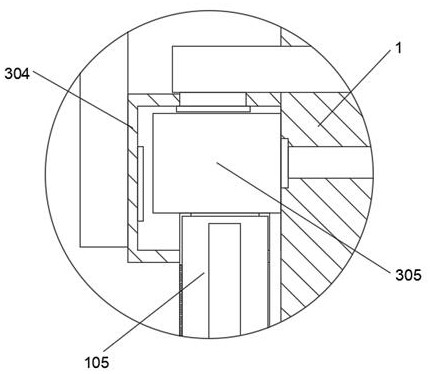

[0035] A coal-fired boiler flue gas decarburization device, including a furnace body 1, a first dust collection drawer 101, a support column 102, a split sealed door 103, a heating water tank 104, a blower 105, a frame-shaped support 106, and a convective cyclone decarburization device 2 and the preheating calcining system 3, the heating water tank 104 is fixedly installed in the furnace body 1, and a coal pallet is fixed between the heating water tank 104 and the bottom plate of the furnace body 1, and the coal pallet is provided with ash drop holes, and the coal is placed on the coal On the supporting plate, the support column 102 is fixedly arranged at the four corners of the bottom end of the furnace body 1, the air blower 105 is fixedly arranged on one side of the furnace body 1, the first dust collecting drawer 101 is fixedly arranged at the bottom end of the furnace body 1, and the second A dust collection drawer 101 is used to receive coal ashes, and the sealed door 103...

Embodiment 2

[0051] In Example 1, the carbon is detached by preheating the calcination system 3 and the convective rotary decarburization device 2, wherein the first convective carbon adsorption part 210, the second convective carbon adsorption part 211 and the third convective carbon adsorption part 2 in the convective rotary decarburization device 2 The carbon adsorption part 212 needs to continuously adsorb the carbon dust in the flue gas. When the carbon dust accumulates in the first convective carbon adsorption part 210, the second convective carbon adsorption part 211 and the third convective carbon adsorption part 212, it is generally fixed The method is usually fixed by bolts, the function is too single, and this method is not convenient enough to operate, which affects work efficiency;

[0052] The adsorption chamber 204 is also provided with a support block 213 and a locking assembly 214. The support block 213 is fixed at the bottom of the decarburization chamber 201, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com