CeO2-TiO2 nanorod/graphene denitration catalyst as well as preparation and application thereof

A technology of denitrification catalyst and graphene, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of poor denitrification performance at low temperature, and improve low temperature The effect of denitrification performance, simple preparation process and process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

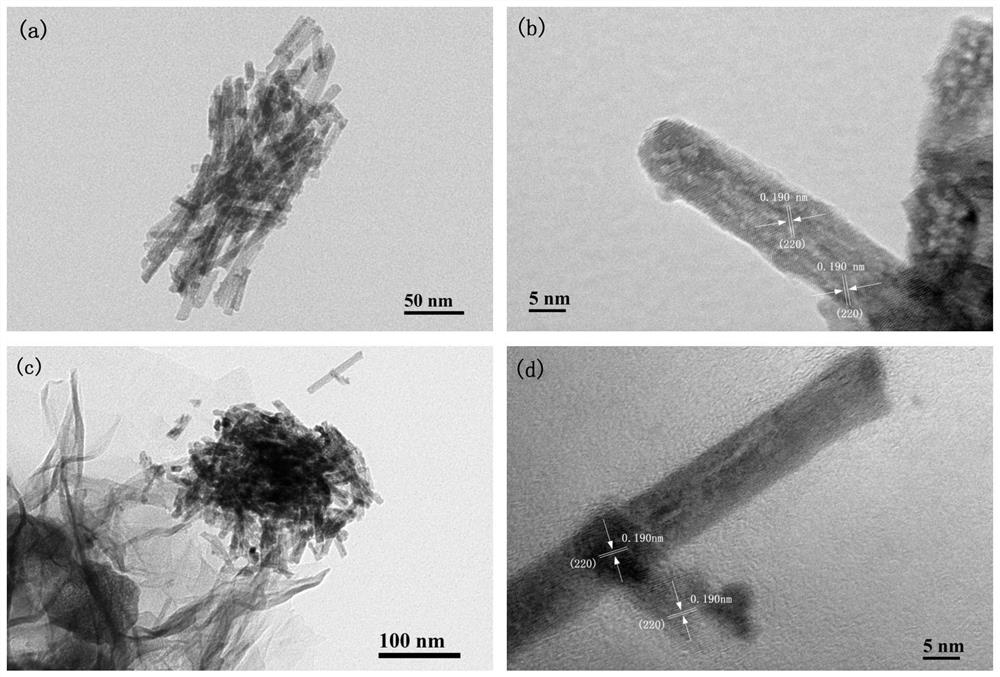

[0072] The invention provides a CeO 2 -TiO 2 Nanorod / graphene denitrification catalyst, which can be applied to NH 3 -In SCR reaction and denitrification of industrial coal-fired flue gas, its preparation method comprises the following steps:

[0073] 1) dissolving the precursor salt containing Ce element and the precursor salt containing Ti in water to prepare a mixed solution;

[0074] 2) add graphene to the mixed solution prepared in step 1), and stir to obtain a suspension;

[0075] 3) adding excess NaOH solution to the suspension prepared in step 2), stirring and mixing to obtain a slurry;

[0076] 4) transferring the slurry prepared in step 3) to a hydrothermal reaction kettle for high-temperature hydrothermal reaction;

[0077] 5) centrifuging, washing, drying, and roasting the product of the hydrothermal reaction in step 4) to obtain CeO 2 -TiO 2 Nanorod / graphene denitrification catalyst.

Embodiment 1

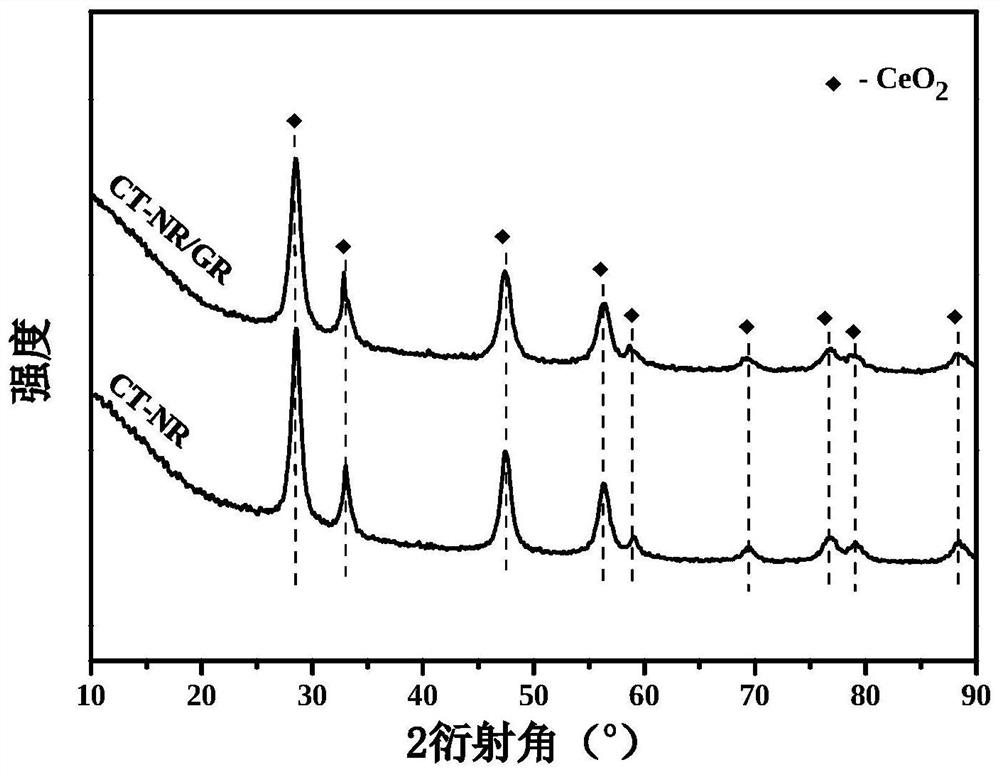

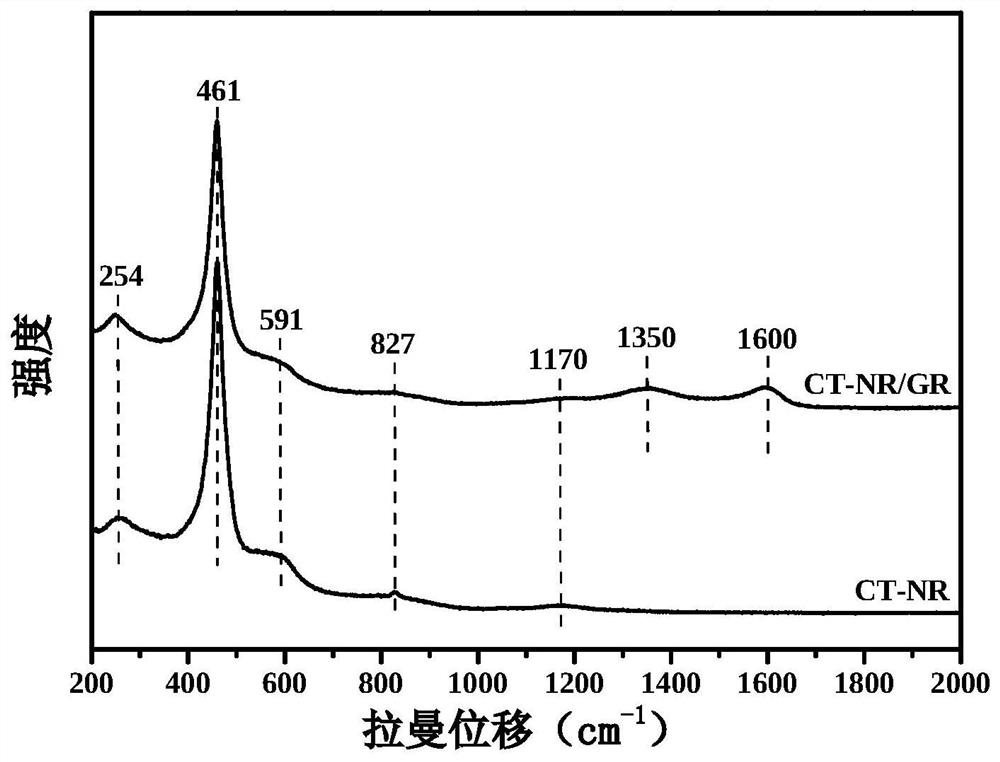

[0101] CeO 2 -TiO 2 Preparation of nanorod / graphene low-temperature denitrification catalyst (abbreviated as CT-NR / GR catalyst)

[0102] Accurately weigh 3.1263g (i.e. 7.2mmol) of Ce(NO 3 ) 3 ·6H 2 O, measure the TiCl of 8ml (ie 0.8mmol) 0.1mol / L 4 Dissolve the solution in 72ml of ultrapure water and stir evenly, then accurately weigh 0.0132g of single-layer graphene and add it to the above mixture for 3 hours to form a suspension; dissolve 38.4000g (ie 960mmol) of NaOH in 80ml of ultrapure water middle. Then, the NaOH solution was added dropwise to the above suspension, and magnetically stirred for 3 hours to mix evenly to form a slurry, ensuring that the pH was greater than or equal to 10. Then the mixed slurry was transferred to a 200ml hydrothermal reaction kettle, and reacted in a dry oven at 100°C for 24h. After cooling down to room temperature, centrifuge and wash with ultrapure water until the pH does not change (at 7), and there is no Cl - Detected (AgNO 3 de...

Embodiment 2

[0119] Accurately weigh 1.7368g (ie 4.0mmol) of Ce(NO 3 ) 3 ·6H 2 O, measure the TiCl of 40ml (ie 4.0mmol) 0.1mol / L 4 Dissolve the solution in 40ml of ultrapure water and stir evenly, then accurately weigh 0.0051g of single-layer graphene and add it to the above mixture for 3 hours to form a suspension; dissolve 38.4000g (ie 960mmol) of NaOH in 80ml of ultrapure water middle. Then, the NaOH solution was added dropwise to the above suspension, and magnetically stirred for 3 hours to mix evenly to form a slurry, ensuring that the pH was greater than or equal to 10. Then the mixed slurry was transferred to a 200ml hydrothermal reaction kettle, and reacted in a dry oven at 100°C for 24h. After cooling down to room temperature, centrifuge and wash with ultrapure water until the pH does not change (at 7), and there is no Cl - Detected (AgNO 3 detection). The product was dried in a drying oven at 70°C for 12 hours, and ground evenly. Finally, in a tube furnace, 300ml / min of N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com