Novel driving cabin heating system

A heating system, a new type of technology, applied in electric heating devices, ohmic resistance heating, vehicle maintenance, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the electric heating front windshield glass is as follows: the electric heating tungsten wire with a diameter of 0.018 mm to 0.033 mm is laid on the PVB film, the float glass for automobiles is put on the laminator, and the electric heating tungsten wire is covered with The PVB film is made by putting down the upper piece of glass and pressing it.

[0026] The preparation method of the side window glass in the electrically heated triangular area is as follows: cloth the electrically heated tungsten wire with a diameter of 0.018 mm to 0.033 mm on the PVB film, put the float glass for automobiles on the laminator, and put it into the electric heating The PVB film of tungsten wire is made by pressing down the upper piece of glass.

[0027] Described carpet dust-proof and sound-insulating layer is positioned at the bottom layer of graphene heating carpet; Described graphene heating layer is positioned between carpet dust-proof and sound-insulating ...

Embodiment

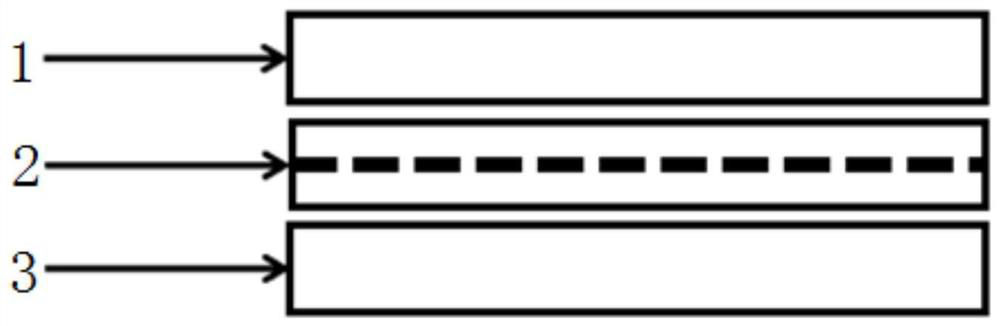

[0029] A new type of cockpit heating system, including electric heating front windshield, electric heating triangular side window glass and graphene heating carpet. The structures of the electrically heated front windshield glass and the electrically heated triangular area side window glass are as follows: figure 1 As shown, the electrically heated front windshield glass and the electrically heated triangular area side window glass are composed of the upper sheet 1 of float glass for vehicles, the PVB2 covered with tungsten wires and the lower sheet 3 of float glass for vehicles.

[0030] Among them, the structure of the upper float glass 1 for vehicles and the lower float glass 3 for vehicles is similar in structure, and the rough glass is cut into large pieces, cut, edged, washed and dried, sprayed with powder, baked and bent to make a semi-finished laminated glass , after cleaning the powder, it can be placed on the lamination machine to prepare for lamination with PVB.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap