Fuel cell bipolar plate sealing material and preparation method and application thereof

A fuel cell and sealing material technology, applied in fuel cell components, sealing/supporting devices, final product manufacturing, etc., can solve problems such as slow vulcanization speed, difficult molding, and failure to meet low-cost requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

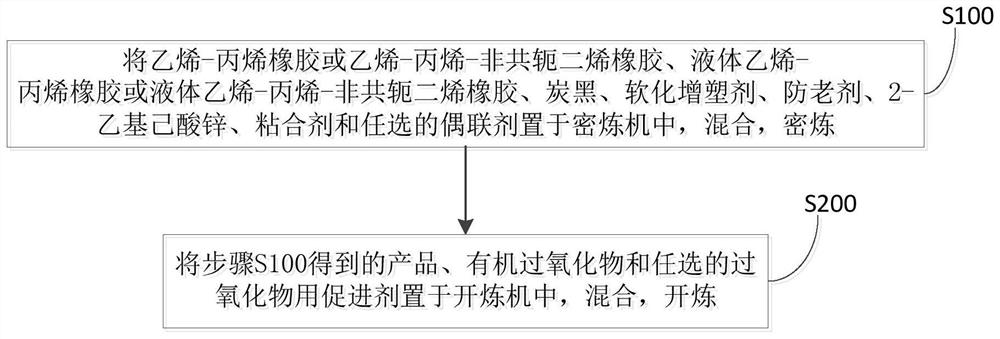

Method used

Image

Examples

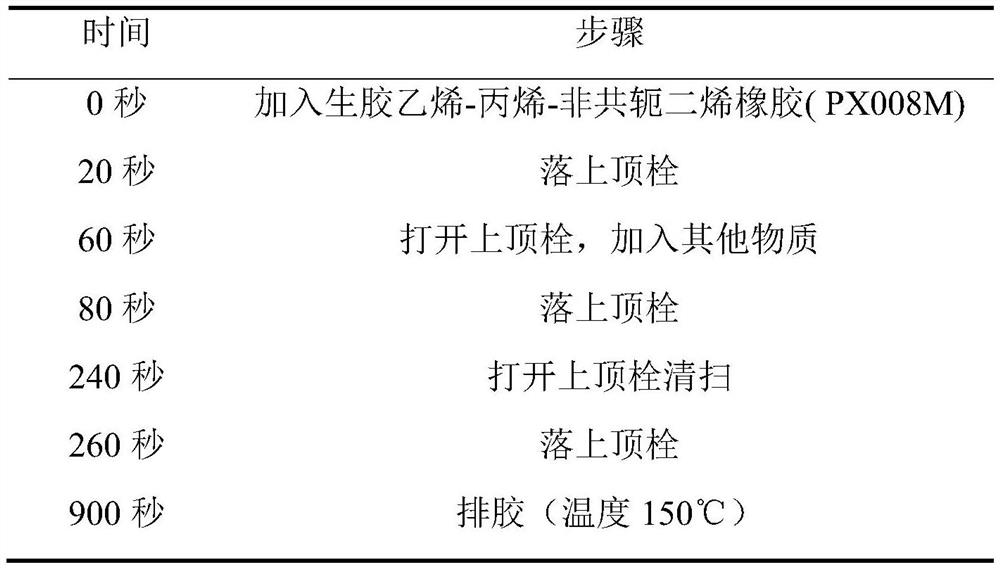

Embodiment 1

[0080] The materials used in this example are as follows:

[0081] Ethylene-propylene-non-conjugated diene rubber PX008M, Mitsui Chemicals;

[0082]Liquid ethylene-propylene-non-conjugated diene rubber TP-67, Lion Copolymer;

[0083] Zinc 2-ethylhexanoate ZEH-DL, Struktol;

[0084] Anti-aging agent TMQ, Sennics;

[0085] Carbon black SP5000, Cabot Chemical (Tianjin) Co., Ltd.;

[0086] Paraffin oil, Airyr Composites Co., Ltd.;

[0087] 2,4-Dichlorobenzoyl peroxide, AkzoNobel Peroxide Co., Ltd.;

[0088] Triallyl isocyanurate, Jiangsu Huaxing New Material Technology Co., Ltd.;

[0089] N,N'-m-phenylene bismaleimide, Jin Changsheng;

[0090] Vinyltrimethoxysilane, Shin-Etsu Chemical;

[0091] Resorcinol-formaldehyde condensate, ALLNEX (USA);

[0092] The composition of the fuel cell bipolar plate sealing material of this embodiment is shown in Table 1:

[0093] Table 1

[0094] Types of raw materials Recipe / Serving Ethylene-propylene-non-conjugated die...

Embodiment 2

[0103] The composition of the fuel cell bipolar plate sealing material in this embodiment is shown in Table 3:

[0104] table 3

[0105]

[0106]

[0107] The preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com