Alcohol production process

A production process, alcohol technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of affecting the processing efficiency of equipment, increasing the cost of alcohol production, and increasing the aging time of alcohol preparation, so as to reduce the volume, shorten the time consumption, and fine uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

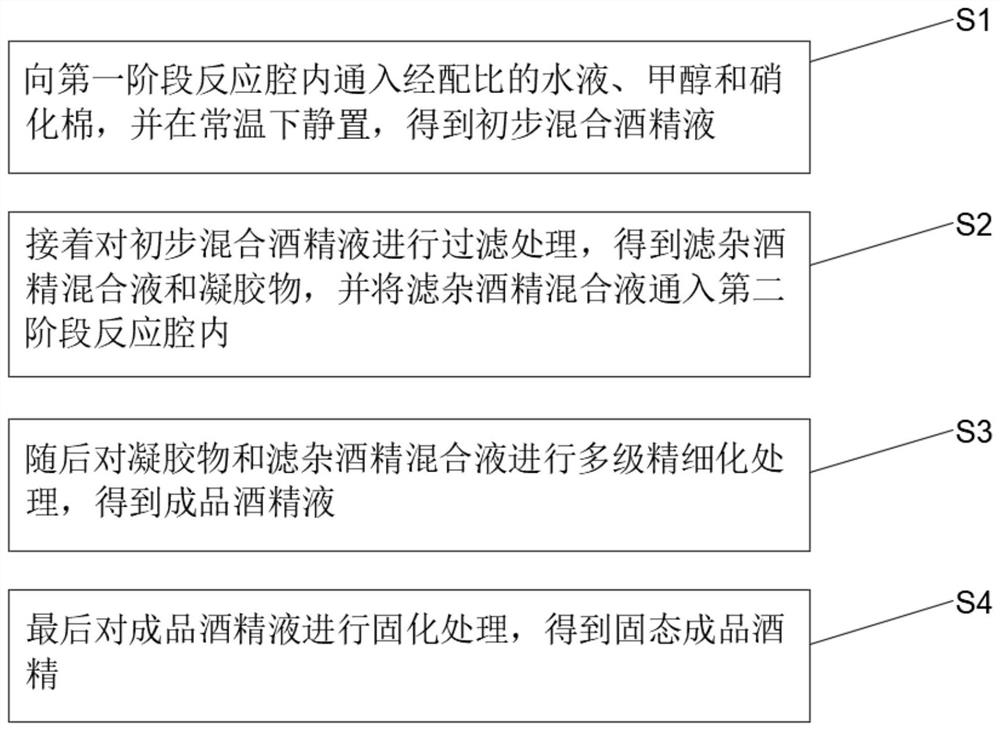

[0040] S1. Pass the proportioned water solution, methanol and nitrocellulose into the reaction chamber of the first stage, and let it stand at room temperature to obtain a preliminary mixed alcohol solution.

[0041] Industrial solid alcohol is mainly composed of an appropriate amount of water and a large amount of methanol, which is added with nitrocellulose, also known as nitrocellulose, which is mainly obtained by the esterification reaction of refined cotton with concentrated nitric acid and concentrated sulfuric acid. During the extraction process, it plays the role of increasing the viscosity of the alcohol liquid, solidifies the alcohol, and after adding the raw material ratio, let the raw materials stand at room temperature, so that the nitrocellulose can blend with the liquid at room temperature , to avoid excessive heating of nitrocellulose, increase the dissolution rate, and then destroy the mixing activity of nitrocellulose and methanol.

[0042] In addition, in th...

specific Embodiment 2

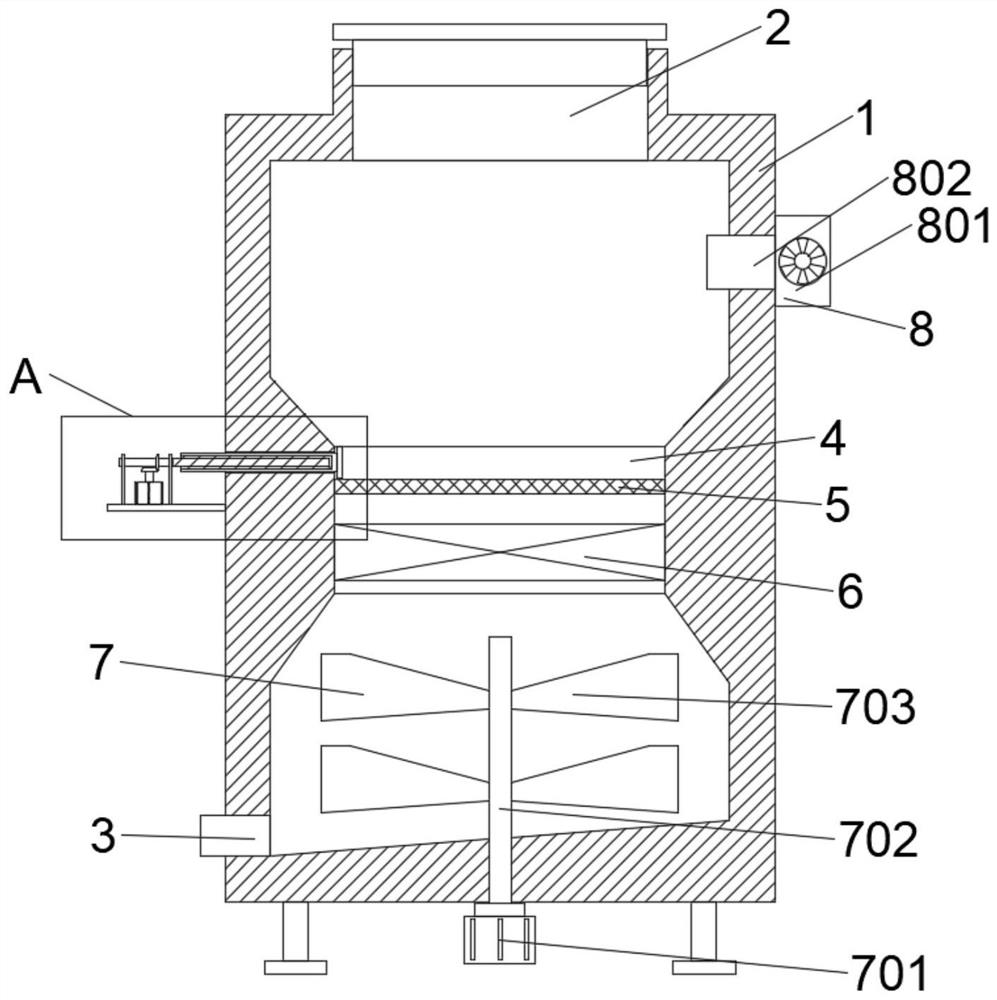

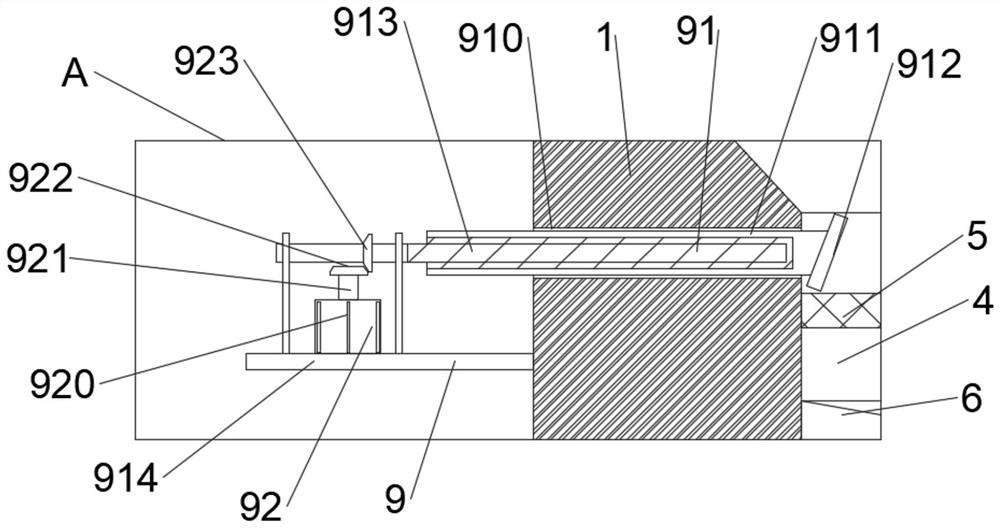

[0067] like Figure 2 to Figure 4 As shown, a kind of alcohol production process, comprises material reaction box 1 and is used for carrying out the gas transmission mechanism 8 that the gel is pressurized and crushed, and the inside of described material reaction box 1 is provided with first stage reaction chamber and second stage Reaction chamber, the reaction chamber of the first stage is located above the reaction chamber of the second stage, the air delivery mechanism 8 includes a booster pump 801 arranged on the outer surface of the material reaction box 1, and the outlet end of the booster pump 801 is connected with Air delivery pipe 802, the air delivery pipe 802 passes through the material reaction box 1 and extends into the first-stage reaction chamber. The top of the material reaction box 1 is provided with a feed pipe 2 communicating with the first-stage reaction chamber. The bottom end of the right side is provided with a liquid outlet pipe 3 communicating with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com