Combined garbage treatment equipment

A garbage treatment equipment and combined technology, applied in chemical instruments and methods, solid separation, solid waste removal, etc., can solve the problems of heavy air pollution, inability to classify, and inability to fall to filter, etc., to achieve the effect of increasing the rate of drop filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

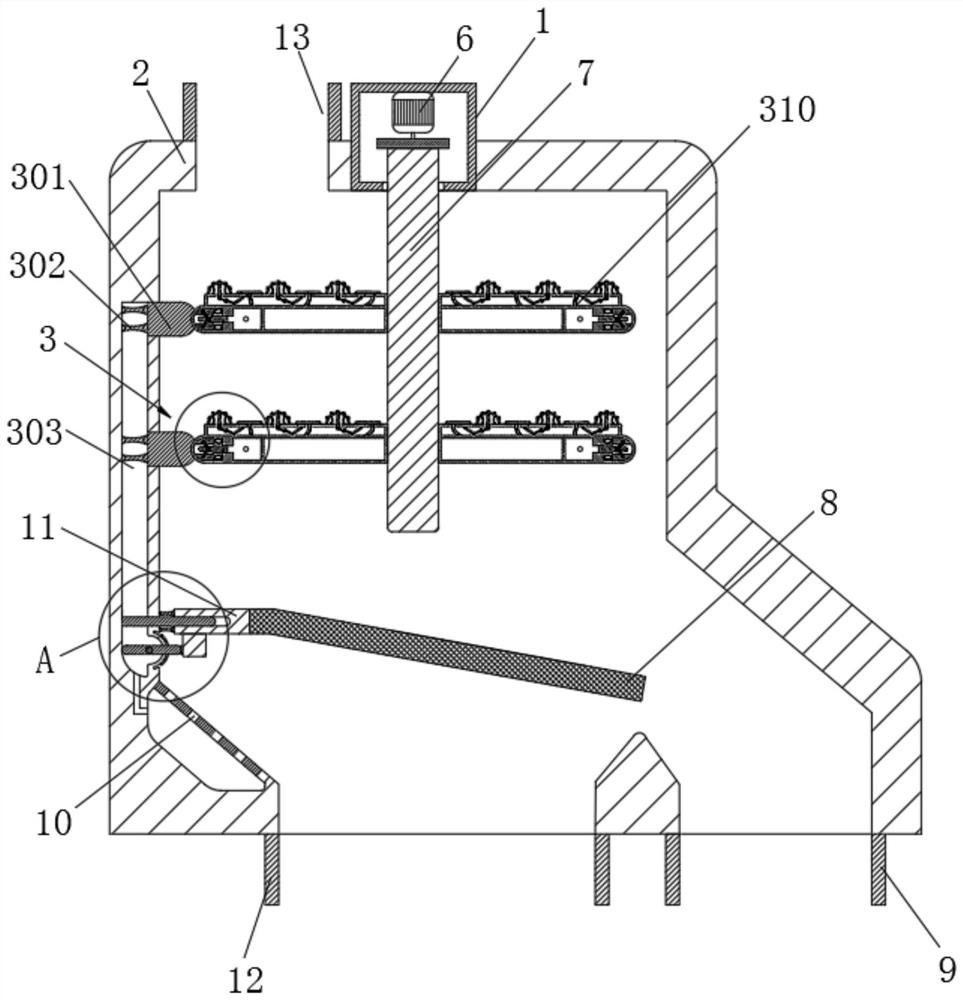

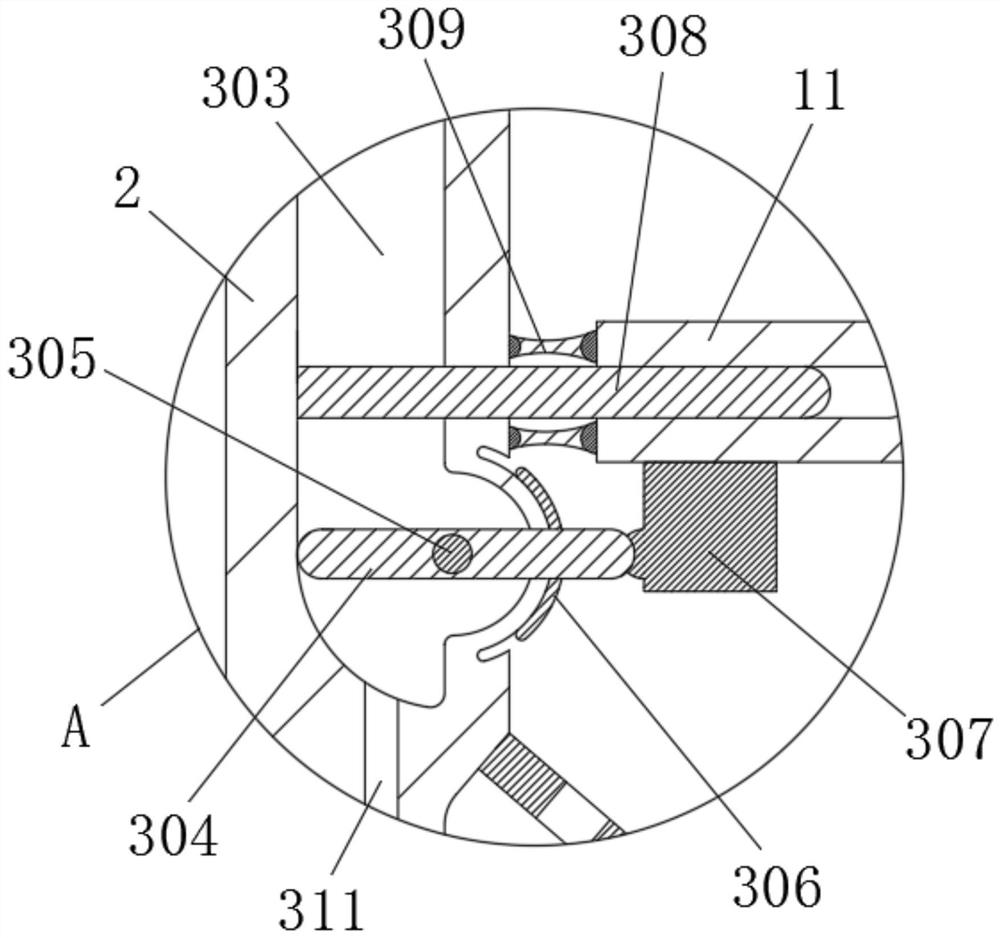

[0022] Such as Figure 1-5As shown, the present invention provides a technical solution: a combined garbage disposal device, including a box body 2, the inner wall of the box body 2 is provided with an insertion slot, the slide plate 306 is inserted into the inner wall of the box body 2 through the insertion slot, and the stirring rod There is a cap on the back of the inner wall of 310, the top of the box body 2 is fixedly connected with the protection box 1, the top of the box body 2 is fixedly connected with the inlet 13, the bottom of the box body 2 is fixedly connected with the small particle outlet 12 and the large particle outlet 9, and the bottom of the box body 2 is fixed Connected with a deflector swash plate 10, the surface of the deflector slant plate 10 is provided with a circular hole, the top of the inner wall of the protection box 1 is fixedly connected with a motor 6, and one end of the motor 6 is fixedly connected with a rotating rod A7 through a coupling, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com