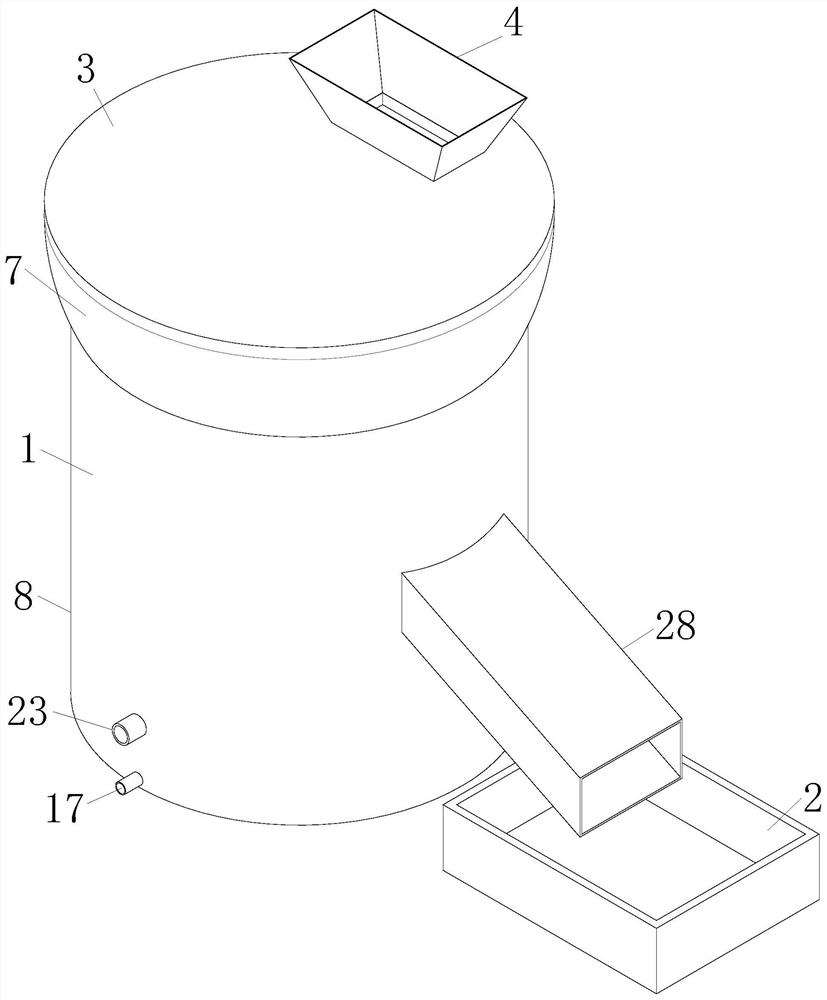

Polystyrene foam plastic reshaping granulation cleaning equipment

A foam and polystyrene technology, applied in the field of polystyrene foam remolding granule cleaning equipment, can solve problems such as waste of water resources, environmental damage, machine damage, etc., to avoid a large amount of waste, avoid secondary pollution, The effect of protecting water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

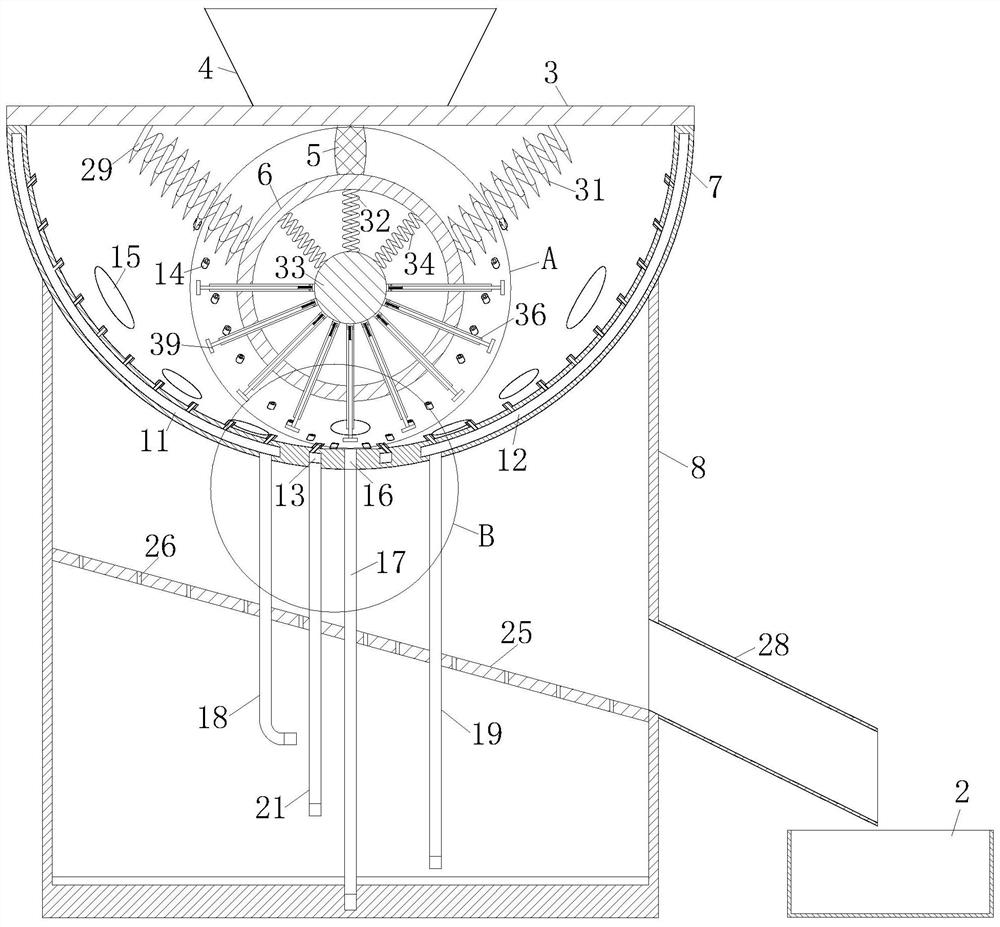

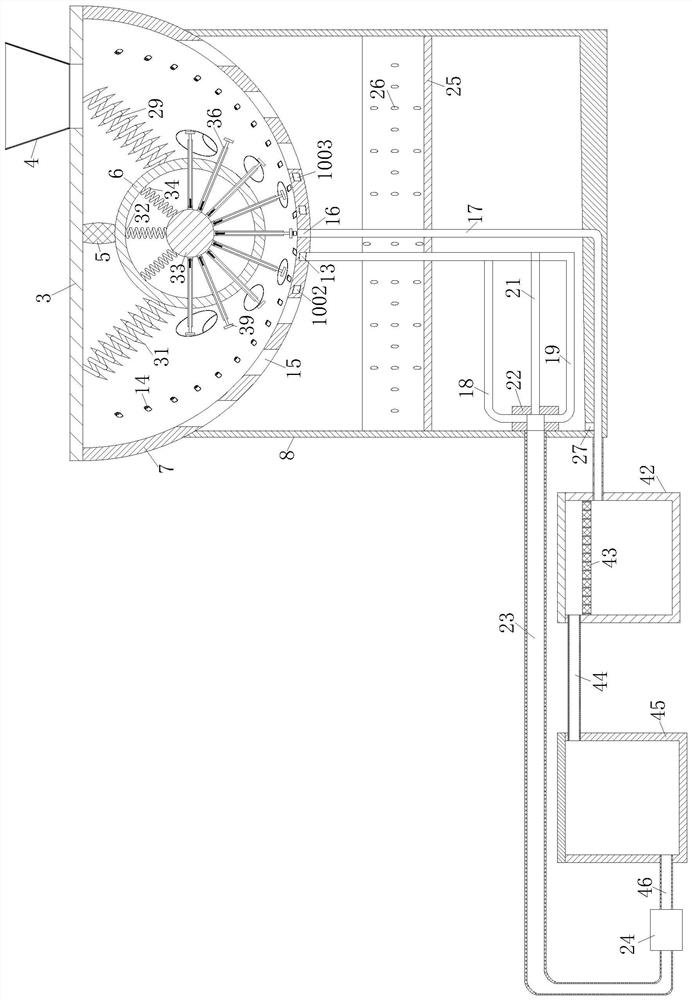

[0034] As an embodiment of the present invention, a plurality of first springs 29 are uniformly fixed on the upper end of the iron ball 6 .

[0035] During work, polystyrene foam fragments are put into the cleaning tank 7 through the feeding tank 4. At this time, the external water pump 24 is turned on, and the water flow enters the flow divider 22 through the fourth water inlet pipe 23, and the flow divider 22 controls the flow of water into the first flow divider. After the water inlet pipe 18, the water flows through the first water tank 11 and enters the high-pressure nozzle 14 on the left side of the cleaning tank 7. The high-pressure nozzle 14 impacts the polystyrene foam fragments on the left side of the cleaning tank 7, so that the polystyrene foam fragments and the water flow are continuous. The ground impacts the iron ball 6 and the extension rod 39, so that the iron ball 6 moves to the right side of the cleaning tank 7 and impacts the polystyrene foam fragments on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com