Cordierite-based glass ceramic combined silicon carbide ceramic material and preparation method thereof

A technology of silicon carbide ceramics and glass-ceramics, applied in the field of ceramic materials, can solve the problems of reducing liquid phase, unfavorable liquid phase sintering, and no silicon carbide, and can reduce the sintering temperature, which is beneficial to popularization and application and industrial technology, and improves the The effect of chemical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

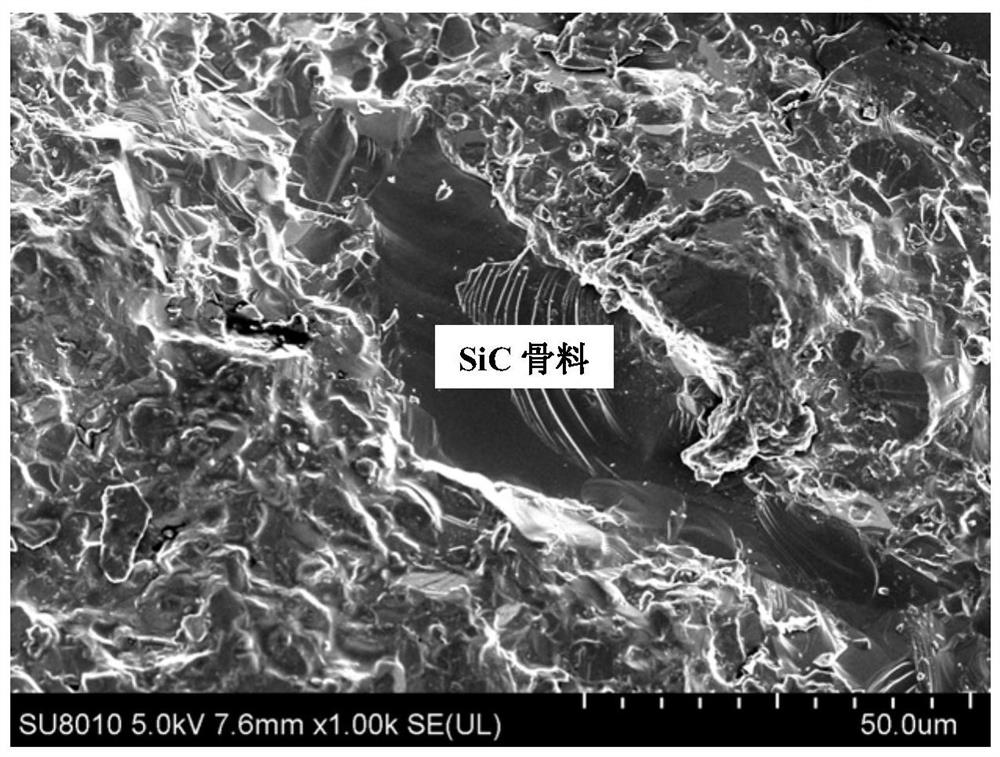

Image

Examples

Embodiment 1

[0023] 1. In this embodiment, a cordierite-based glass-ceramic bonded silicon carbide ceramic material includes a base material and a binder. The base material is composed of cordierite-based glass-ceramic powder (particle size 75 μm) 30 wt%, oxidation pretreated silicon carbide Aggregate 70wt% (made from silicon carbide aggregates oxidized at 1000°C for 2 hours, 30wt% with a particle size of 30 mesh, 10wt% with a particle size of 80 mesh, 10wt% with a particle size of 120 mesh, and 20wt% with a particle size of 325 mesh). Among them, the composition of cordierite-based glass-ceramic powder is MgO 17wt%, Al 2 o 3 22 wt%, SiO 2 60 wt%, Li 2 O 1 wt%. The binding agent is a PVA solution with a concentration of 5wt%, and its dosage is 8wt% of the base material.

[0024] 2. The preparation method of the cordierite-based glass-ceramic bonded silicon carbide ceramic material in this embodiment, the steps are as follows:

[0025] (1) After mixing according to the composition rati...

Embodiment 2

[0029] 1. In this embodiment, a cordierite-based glass-ceramic bonded silicon carbide ceramic material includes a base material and a binder. The base material is composed of cordierite-based glass-ceramic powder (particle size 35 μm) 20 wt%, oxidation pretreated silicon carbide Aggregate 80wt% (made from silicon carbide aggregates oxidized at 1100°C for 1 hour, 40wt% with a particle size of 30 mesh, 10wt% with a particle size of 50 mesh, 10wt% with a particle size of 200 mesh, and 20wt% with a particle size of 325 mesh). Among them, the composition of cordierite-based glass-ceramic powder is MgO 15wt%, Al 2 o 3 25 wt%, SiO 2 57 wt%, Li 2 O 3wt%. The binding agent is a PVA solution with a concentration of 5wt%, and its dosage is 12wt% of the base material.

[0030] 2. The preparation method of the cordierite-based glass-ceramic bonded silicon carbide ceramic material in this embodiment, the steps are as follows:

[0031] (1) After mixing according to the composition ratio...

Embodiment 3

[0035] 1. In this embodiment, a cordierite-based glass-ceramic bonded silicon carbide ceramic material includes a base material and a binder. The base material is composed of cordierite-based glass-ceramic powder (particle size 10 μm) 5 wt%, oxidation pretreated silicon carbide Aggregate 95wt% (made from silicon carbide aggregates oxidized at 1000°C for 2 hours, 35wt% with a particle size of 30 mesh, 10wt% with a particle size of 60 mesh, 10wt% with a particle size of 120 mesh, and 40wt% with a particle size of 325 mesh). Among them, the composition of cordierite-based glass-ceramic powder is MgO 18wt%, Al 2 o 3 25 wt%, SiO 2 56 wt%, Li 2 O 1 wt%. The binding agent is a PVA solution with a concentration of 5wt%, and its dosage is 10wt% of the base material.

[0036] 2. The preparation method of the cordierite-based glass-ceramic bonded silicon carbide ceramic material in this embodiment, the steps are as follows:

[0037] (1) After mixing according to the composition rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com