Polymer dispersant for liquid disperse dye, and synthesis method and application of polymer dispersant

A technology of polymer dispersant and liquid disperse dye, which is used in dyeing, textile and paper making to achieve high grinding efficiency and good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

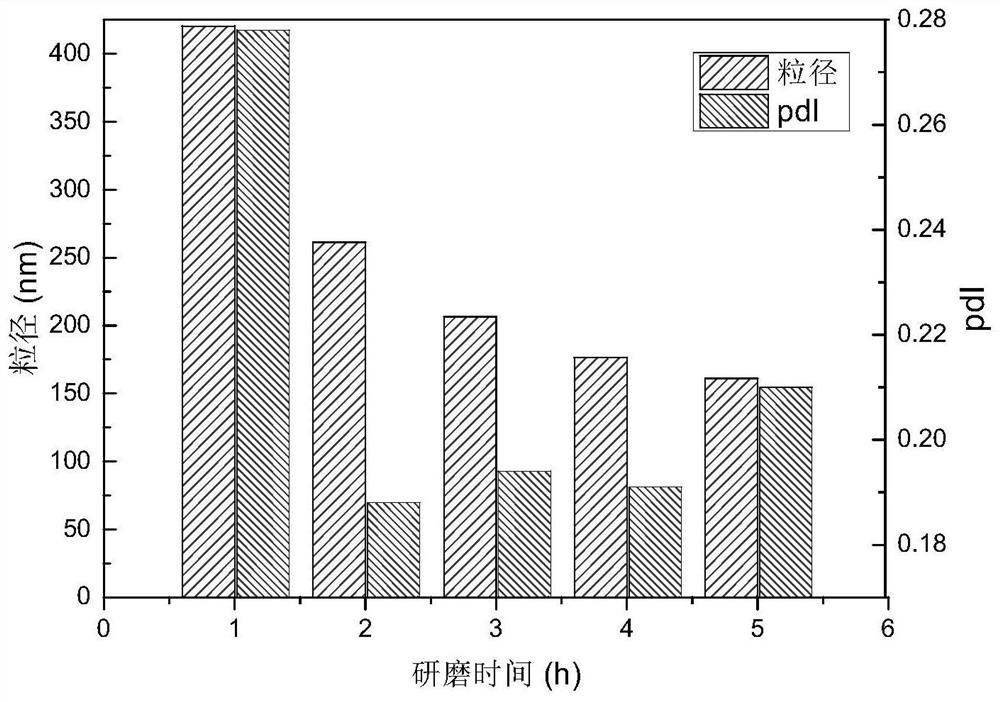

Examples

Embodiment 1

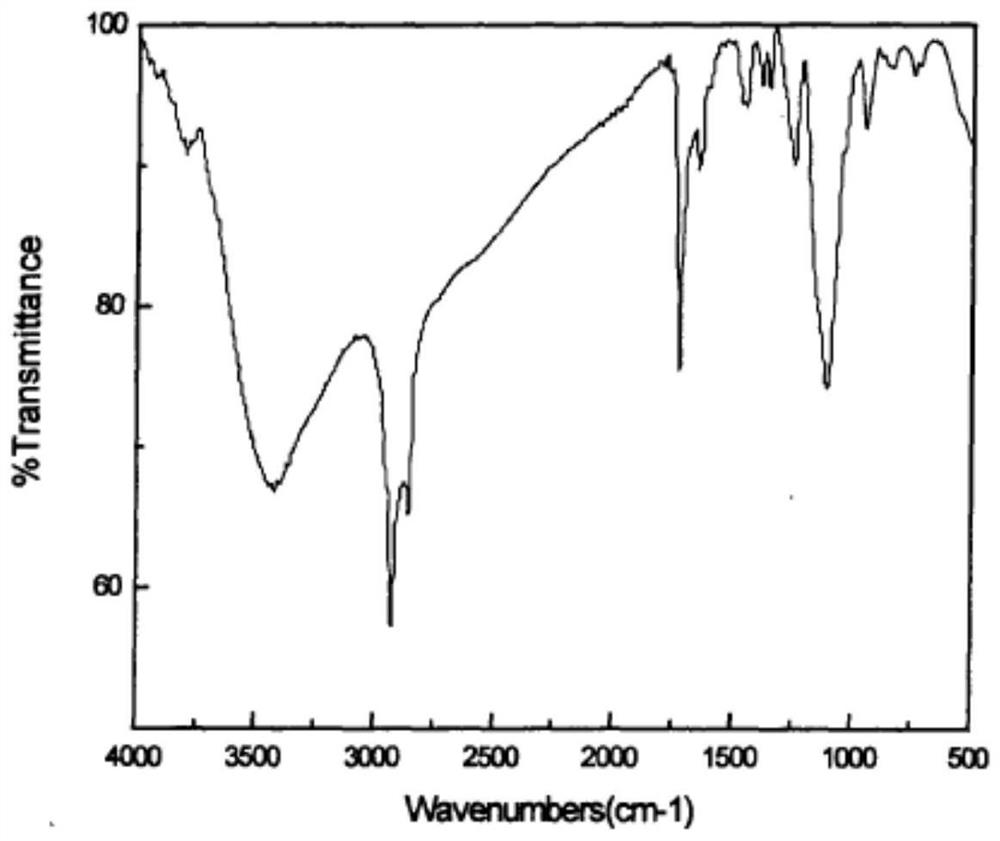

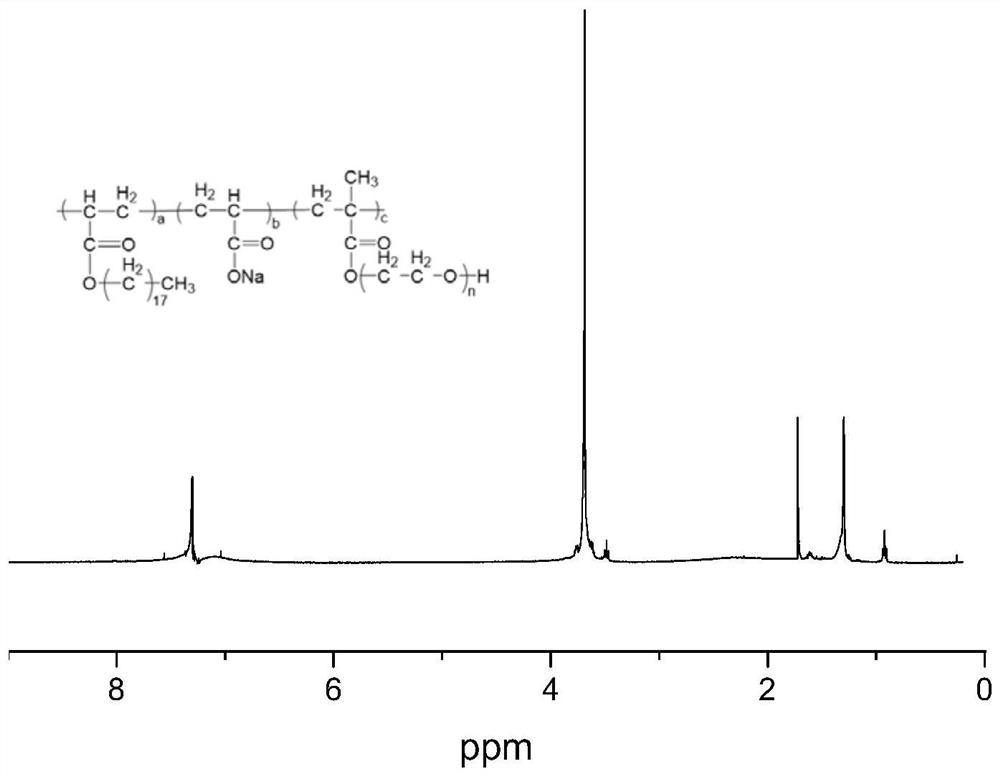

[0029] (1) Synthesis of polymer dispersant:

[0030]

[0031] Among them, n is 15.

[0032] Weigh three monomers of octadecyl methacrylate, acrylic acid, and methoxypolyethylene glycol methacrylate and dissolve them in isopropanol, mix them uniformly, add them to the reaction flask and stir at a certain stirring rate, Fill the reaction flask with nitrogen for 20 minutes to remove the oxygen in the reaction device; dissolve the initiator in acetone, and when the temperature rises to 60°C, add the initiator solution dropwise through a micro-injection pump and control the dropping time for 1 hour; After the reagent is added dropwise, keep it warm at 80°C for 7 hours; after the reaction, drop the temperature and add 30% sodium hydroxide solution dropwise to the reaction system to adjust the pH value of the system to 8.0; discharge through a rotary evaporator The solvent was distilled off, and the product was washed with ether and dried.

[0033] Description: The molar ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com