Synthesis method of polymer emulsifier and application of polymer emulsifier in preparation of hydroxyl silicone oil emulsion

A kind of polymer emulsifier, technology of synthesis method, applied in the application field of preparing hydroxyl silicone oil emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

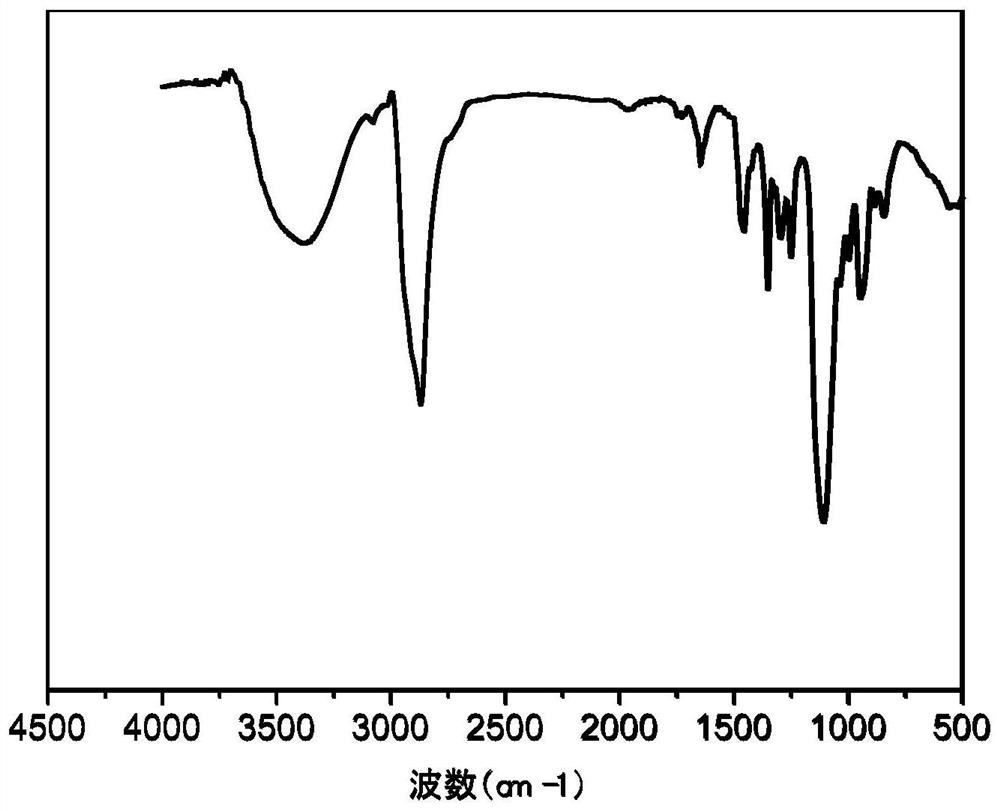

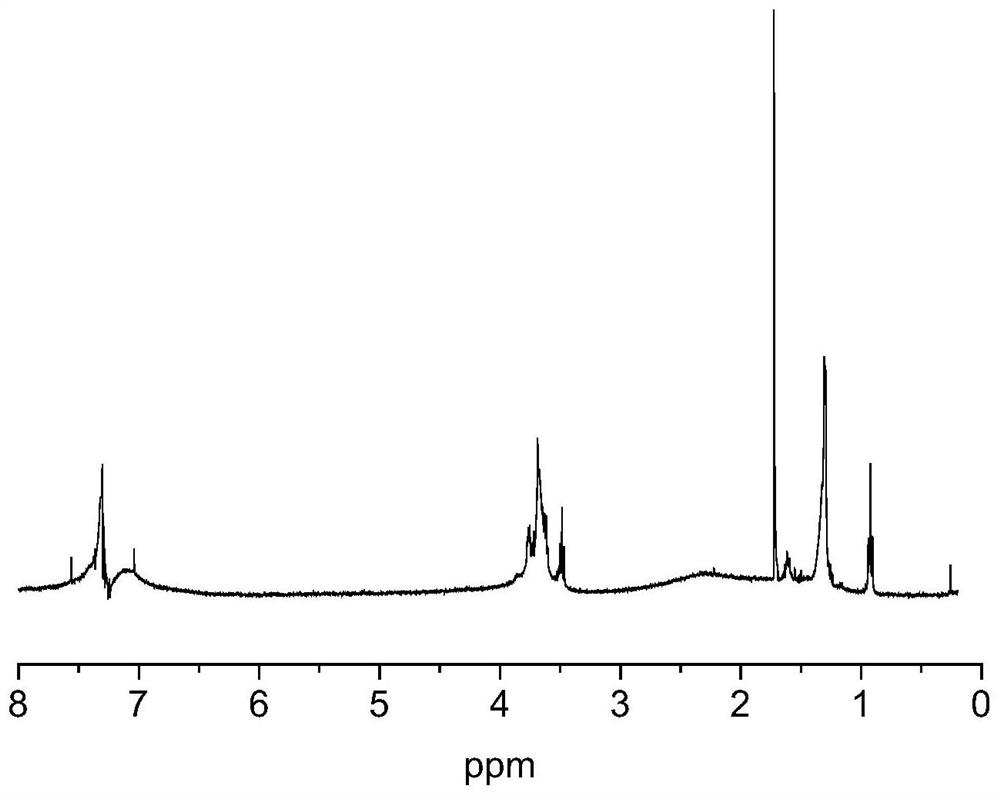

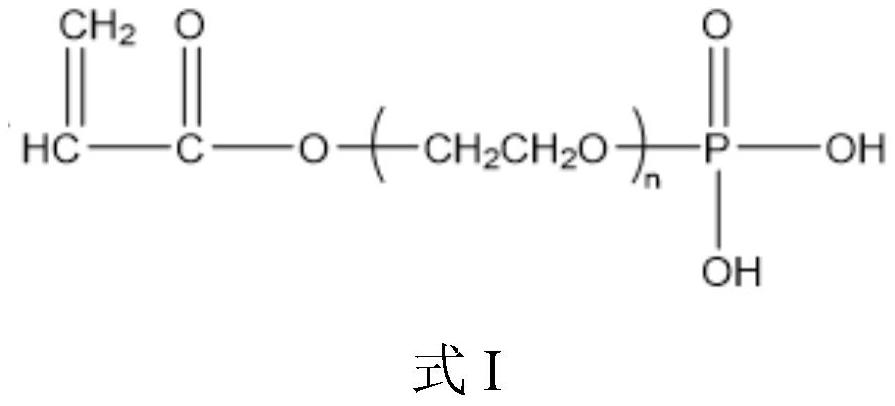

[0029] (1) Synthesis of methoxy polyethylene glycol methacrylate phosphorylated monomer:

[0030]

[0031] Among them, n=15.

[0032] Weigh methoxypolyethylene glycol methacrylate and the polymerization inhibitor hydroquinone and mix evenly, control the temperature at 30°C, add phosphorus pentoxide in batches, raise the temperature to 80°C, react for 5 hours, and the reaction ends Then add an appropriate amount of water and hydrolyze for 2 hours to obtain the methoxypolyethylene glycol methacrylate phosphorylated monomer with the structure of formula I.

[0033] Description: The molar ratio of methoxy polyethylene glycol methacrylate to phosphorus pentoxide is 1.7:1, the polymerization inhibitor is 1% of the total mass of methoxy polyethylene glycol methacrylate monomer, water and The molar ratio of phosphorus pentoxide is 1.78:1. The esterification temperature is 80°C, the esterification time is 5 hours, and the hydrolysis time is 2 hours.

[0034] (2) Synthesis of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com