Diaphragm type pressure tank

A pressure tank and diaphragm type technology, applied in the field of pressure vessels, can solve the problems of high connection strength, good sealing, affecting the normal operation and service life of water pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

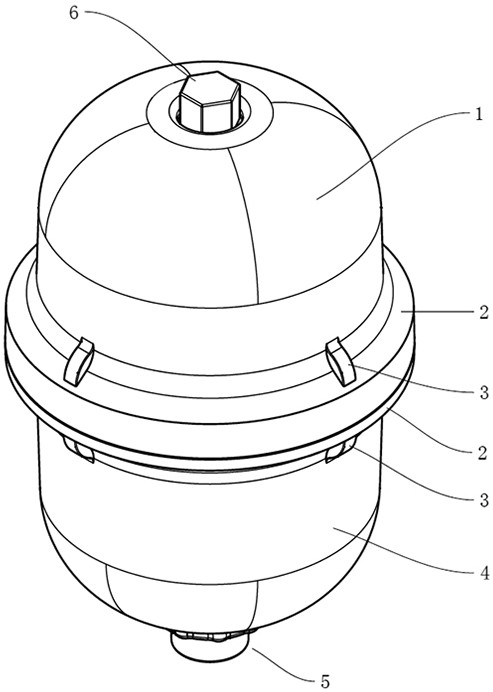

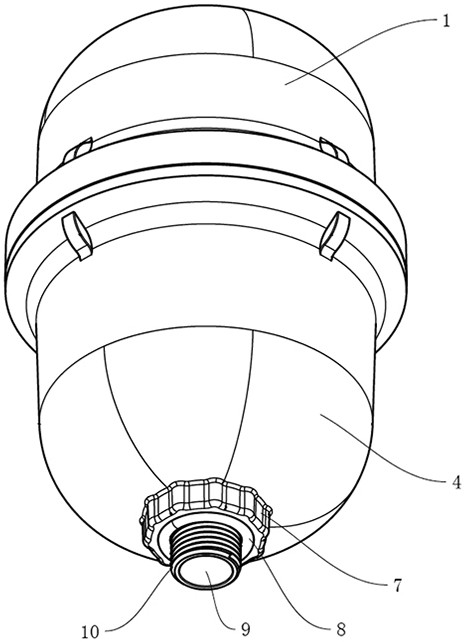

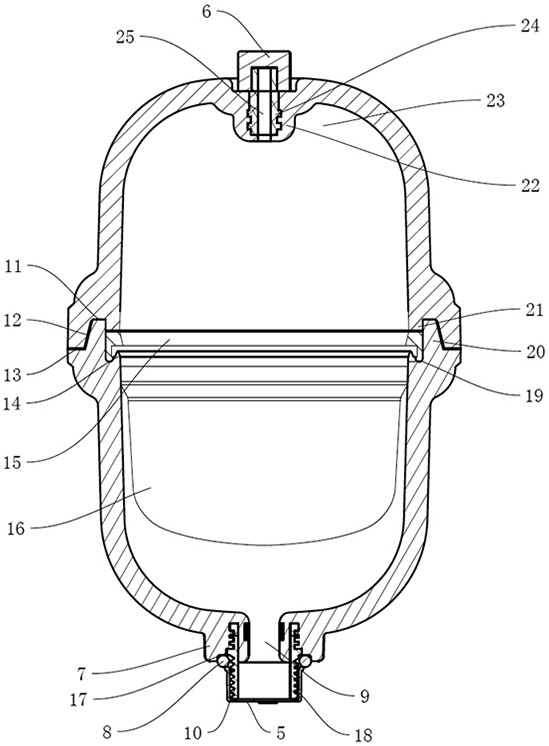

[0027] Such as figure 1 figure 2 image 3 As shown, a diaphragm-type pressure tank includes two half-tanks made of high-strength plastics, the two half-tanks are respectively a gas half-tank 1 and a water half-tank 4, and each half-tank has a docking port With an arc-shaped bottom, the butt joints of the two half-tanks face each other and are sealed and fixed by plastic welding. The bottom of the arc-shaped bottom is provided with a through hole, and a valve core 24 is arranged at the through hole of the air half-tank to form an air hole 25 and a water hole. The outer jacket is provided with a sealing cover. The through hole of the water half-tank is provided with a threaded connection column 10 to form a water hole 9, and a dust cover is placed outside the water hole. A bowl-shaped inner membrane 16 is arranged inside the pressure tank, and the bowl mouth of the inner membrane is turned outward to form an inner membrane connecting edge 30, and a pressure ring 15 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com