Red wine semi-finished product motion detection system for real-time image analysis

A real-time image and motion detection technology, which is applied in image analysis, image enhancement, image data processing, etc., can solve problems such as the lack of universal applicability of the system, the rigidity of the system architecture, and the impact on production speed. Easy to be damaged and aged, the effect of improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

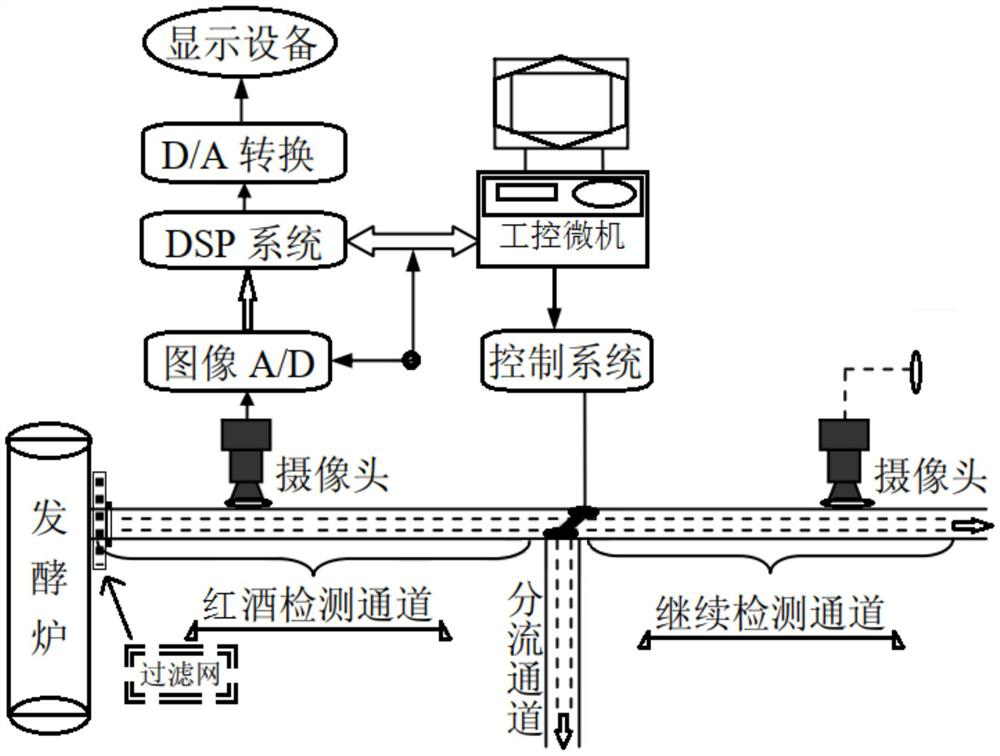

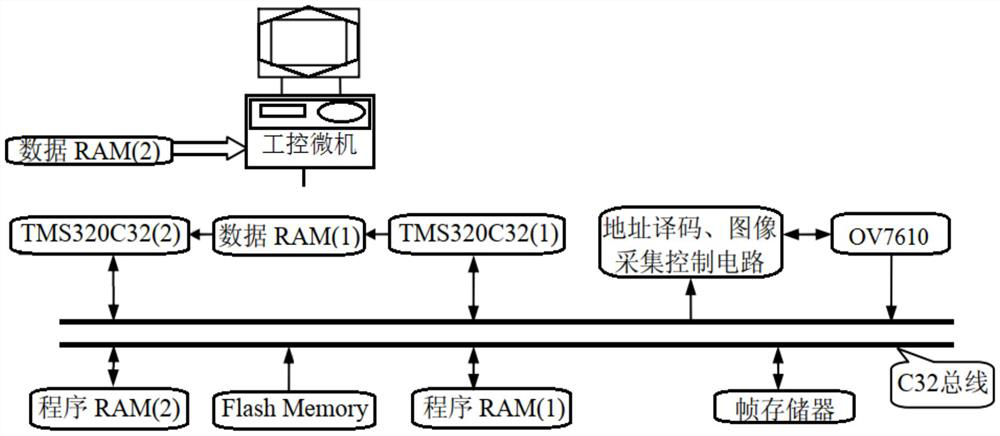

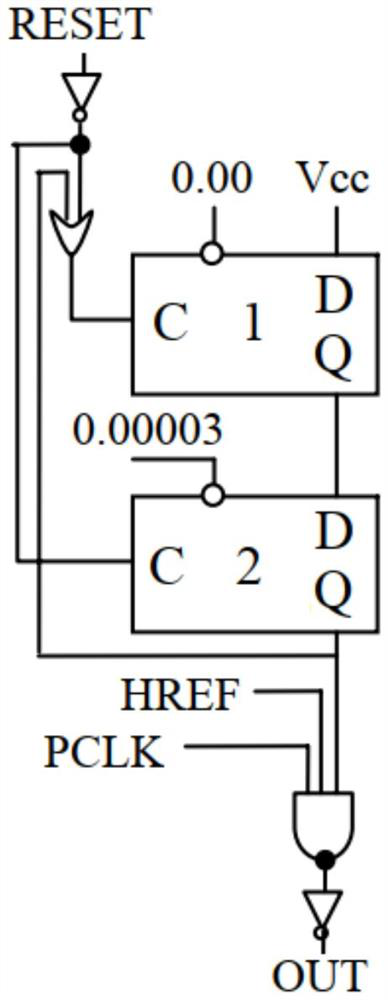

[0083] The technical scheme of the real-time image analysis red wine semi-finished product motion detection system provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

[0084] Based on real-time image analysis, processing and detection, the present invention proposes a red wine semi-finished product motion detection system, integrates morphological filtering, wavelet transform, and multi-scale edge detection, and proposes an edge detection wavelet function structure and algorithm to realize real-time wine semi-finished images based on DSP chips Analysis system, put forward the software programming and system debugging method of DSP system; realize real-time image analysis of semi-finished red wine based on motion detection method.

[0085] The present invention integrates morphological filtering, wavelet transform, and multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com