Discharging system for fluid preparation

A blanking and fluid technology, which is applied in the field of biopharmaceutical fluid equipment, can solve the problems that cannot meet the clean use requirements of biopharmaceuticals, cannot clean dead corners, etc., and achieve the effect of avoiding clogging and slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

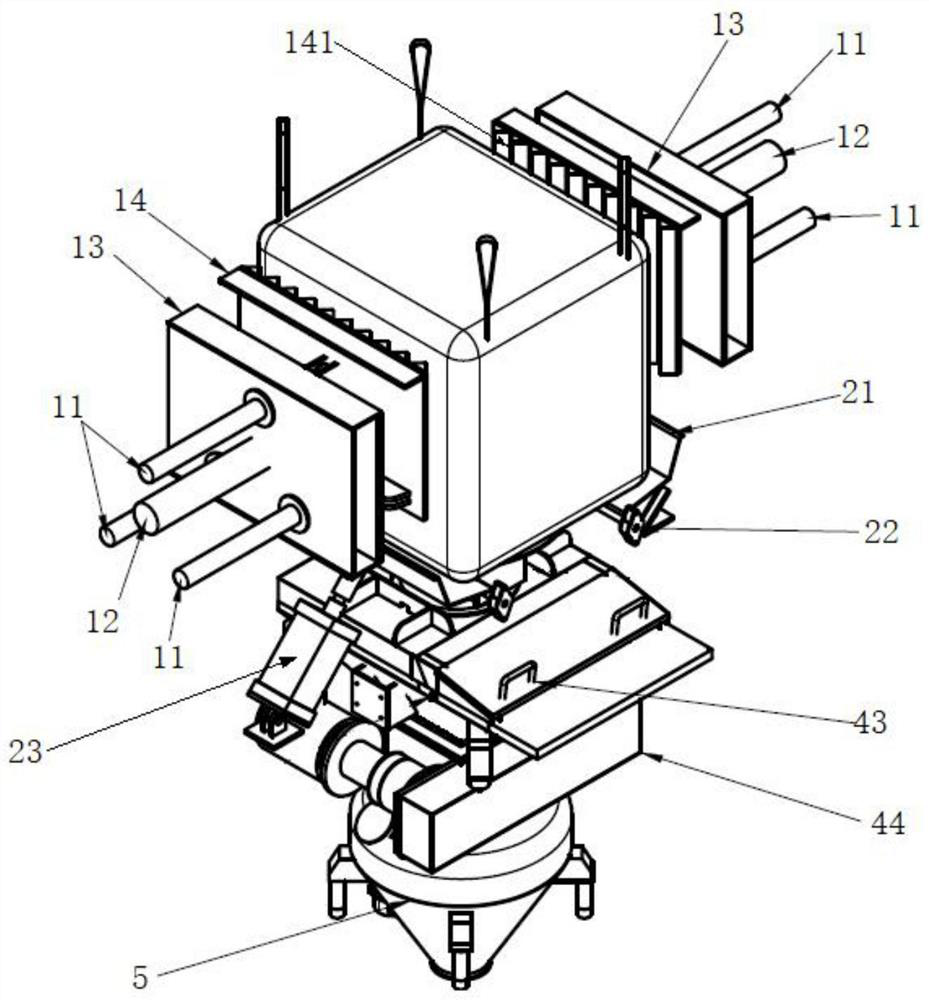

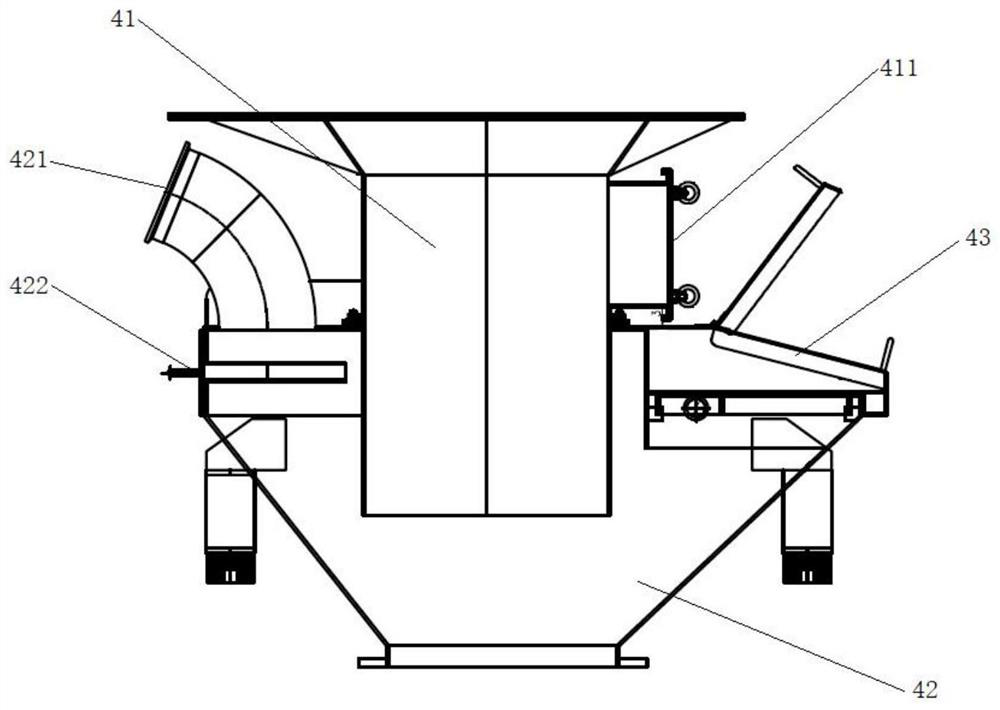

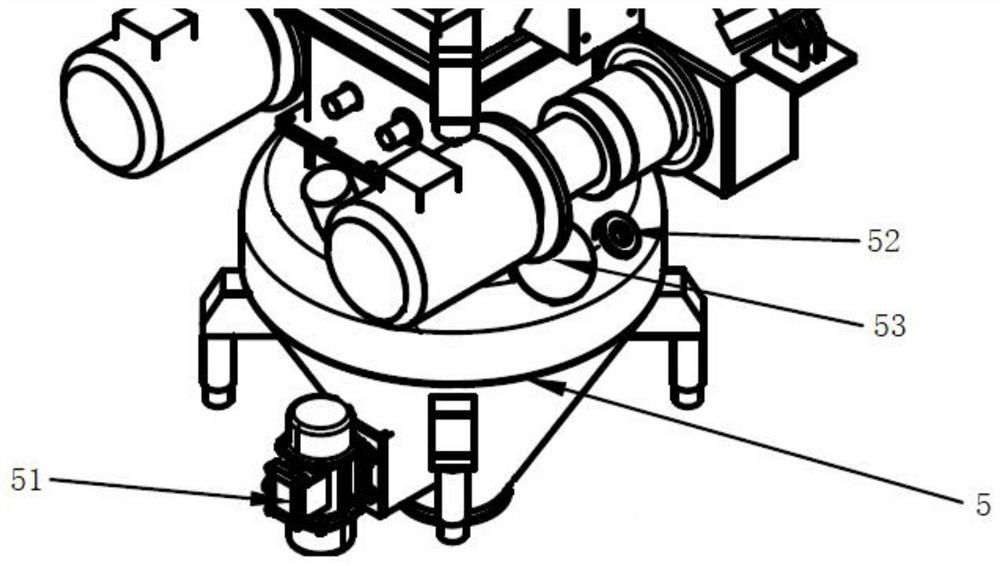

[0031] as attached Figure 1-3 : A blanking system for fluid preparation, comprising an extrusion system, a feeding system and a silo 5; the feed end of the extrusion system corresponds to the feed end of the aerial crane, and the extrusion system connects the feed end of the aerial crane The transported material bags are extruded, the discharge end of the extrusion system corresponds to the feed end of the feeding system, and the discharge end of the feeding system corresponds to the hopper 5; the inner wall of the hopper 5 is inverted conical Structural setting, the inclination angle of the inner wall of the silo 5 is the set angle of repose, and the inner wall of the silo 5 is polished; the extrusion system squeezes the material bag, crushes the agglomerated and hardened material, and the extrusion system The extrusion force is obtained through a large number of te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com