3D printing-based calcium phosphate ceramic high-throughput screening model and preparation method and application thereof

A calcium phosphate ceramic and 3D printing technology, applied in the field of biomedical engineering, can solve the problems of poor induction performance of calcium phosphate ceramics, and achieve the effect of shortening the evaluation period, high reliability and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This example discloses the preparation of calcium phosphate ceramic high flux screening model for different porosity structures and porosity, and investigates the effects of different pore geometries and porosity on calcium phosphate ceramic bone inducing properties. The method of preparing the calcium phosphate ceramic high flux screening model of the present invention, including the following steps:

[0055] (1) Model design:

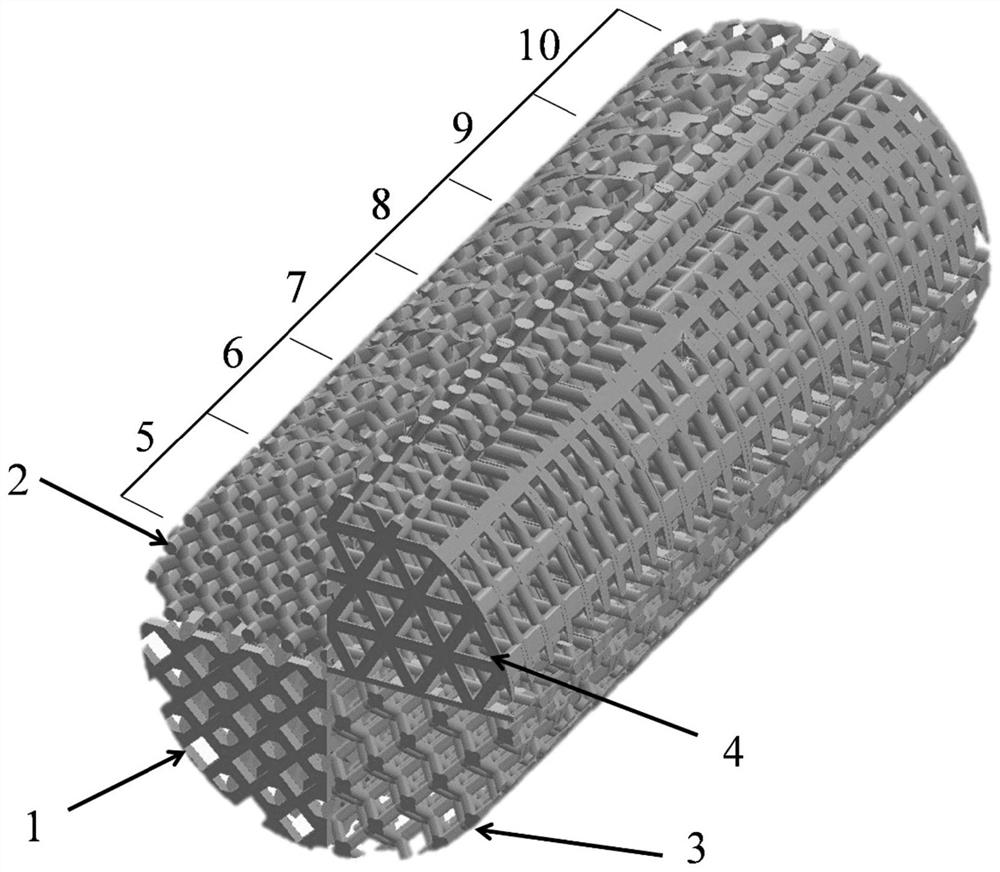

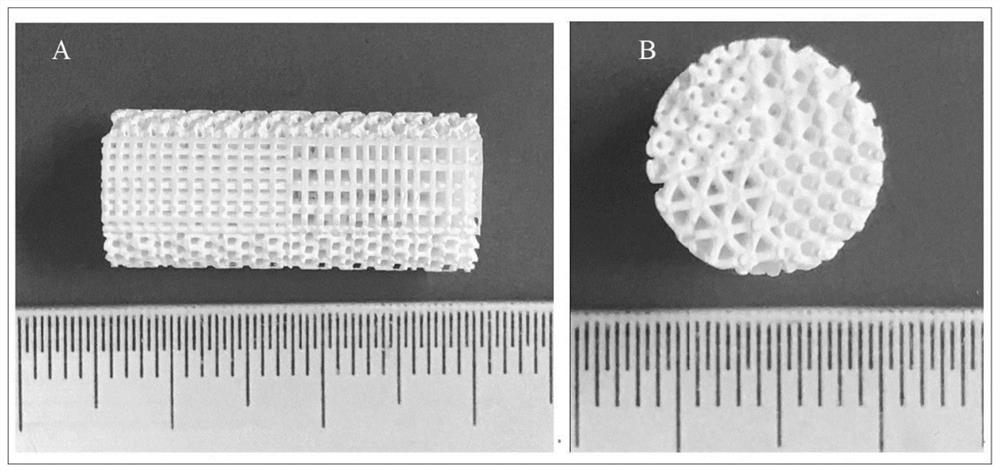

[0056] The calcium phosphate ceramic high flux screen is designed by computer model. The model of the present embodiment is made of the same material, considering shrinkage after sintering, and to ensure the screening experiment, the design model is 17mm, height 34mm. The model includes four types of porosity, each geometric structure comprising 6 porosity, the same vertical direction of different porosity of the same geometry, is sequentially distributed in the porosity size, such as attached figure 1 As shown in: 1 The screening unit of the colum...

Embodiment 2

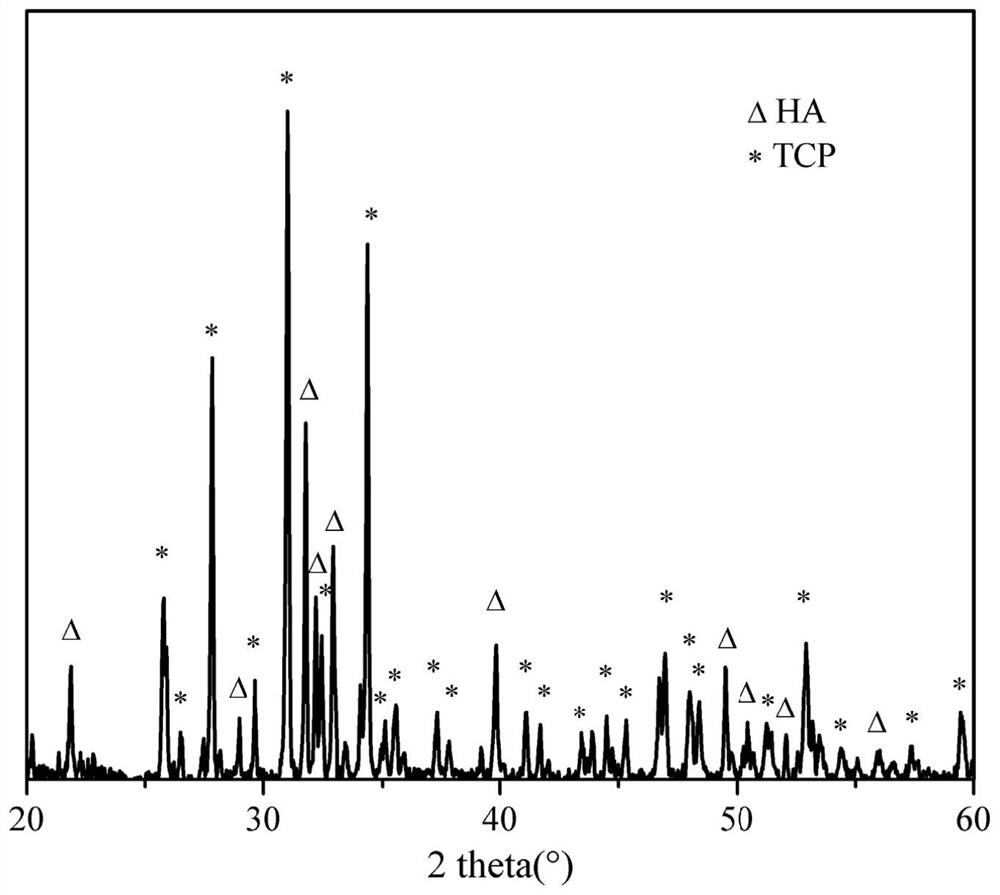

[0066] This example discloses the preparation of calcium phosphate ceramic high flux screening model for the preparation of different substances and pore geometries, and investigated the effects of different substance components and pore geometric structures on calcium phosphate ceramic induction performance. The method of preparing the calcium phosphate ceramic high flux screening model of the present invention, including the following steps:

[0067] This example discloses a method of preparing a 3D printing high-throughput phosphate ceramic screening model of the present invention, including the following steps:

[0068] (1) Model design:

[0069] The high flux model of calcium phosphate ceramic is designed by computer model design software, and the material parameters of each screening unit of the model are different. Considering the contraction after the material is sintered, the design model size is 17mm in diameter and a height of 34 mm. The model includes four kinds of ape...

Embodiment 3

[0079] This example discloses the preparation of different aperture geometries and porecalic acid calcium phosphate ceramic high flux screening models, and investigated different pore geometries and aperture parameters on the induction performance of calcium phosphate ceramic bone. The method of preparing the calcium phosphate ceramic high flux screening model of the present invention, including the following steps:

[0080] (1) Model design:

[0081] The calcium phosphate ceramic high flux screen is designed by computer model. The model of the present embodiment is made of the same material, considering shrinkage after sintering, and to ensure the screening experiment, the design model is 17mm, height 34mm. This model includes four types of geometries, each of which includes 6 different aperture sizes. The same longitudinal distribution of different aperture sizes of the same hole geometry. The four kinds of hole geometry are respectively pair of frame holes, diamond structures, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com