A processing equipment for metal powder recycling handicrafts

A processing equipment and metal powder technology, which is applied in the field of metal powder recycling handicraft processing equipment, can solve the problems of destroying the ecological balance of the soil, waste of resources, and no grass growing, and achieve the effect of improving the drying efficiency of hot air, large contact surface of hot air, and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

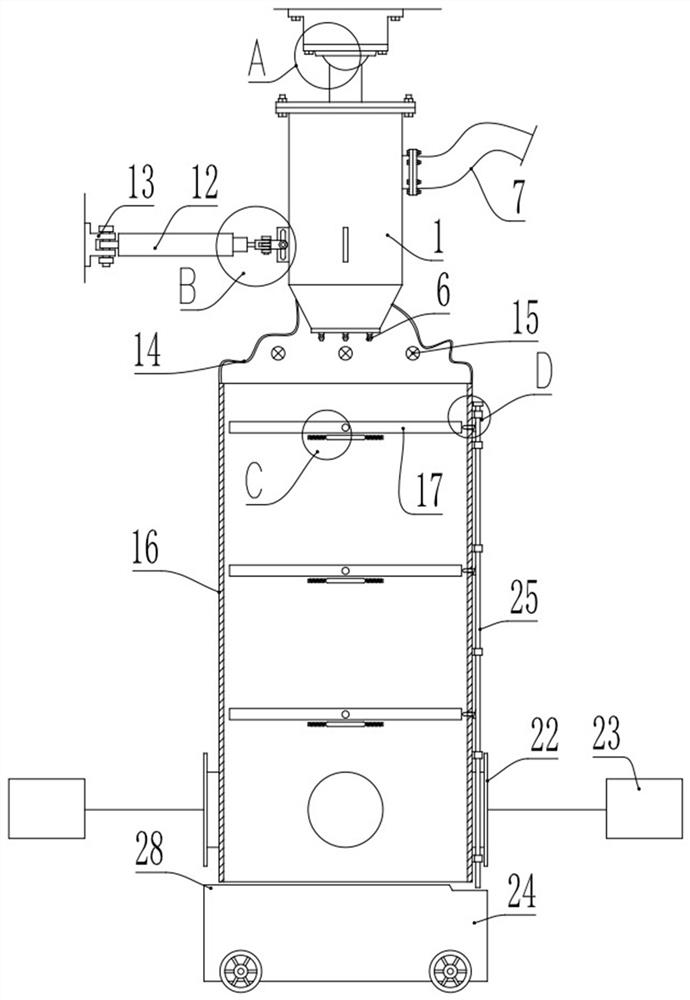

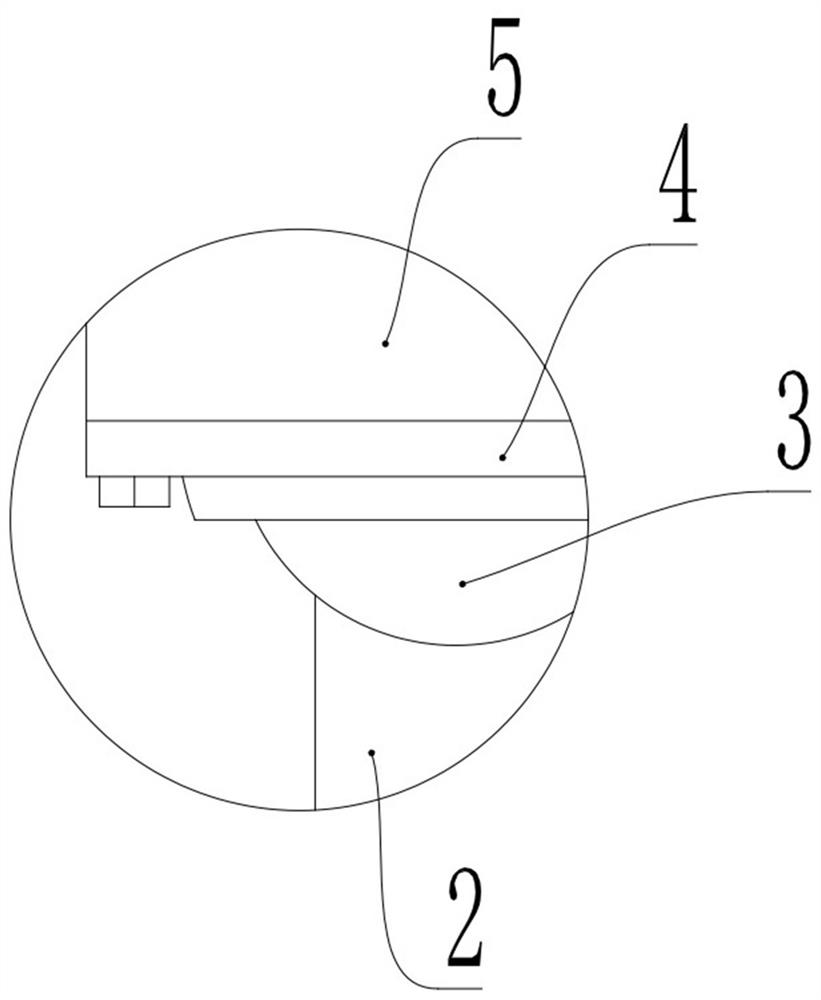

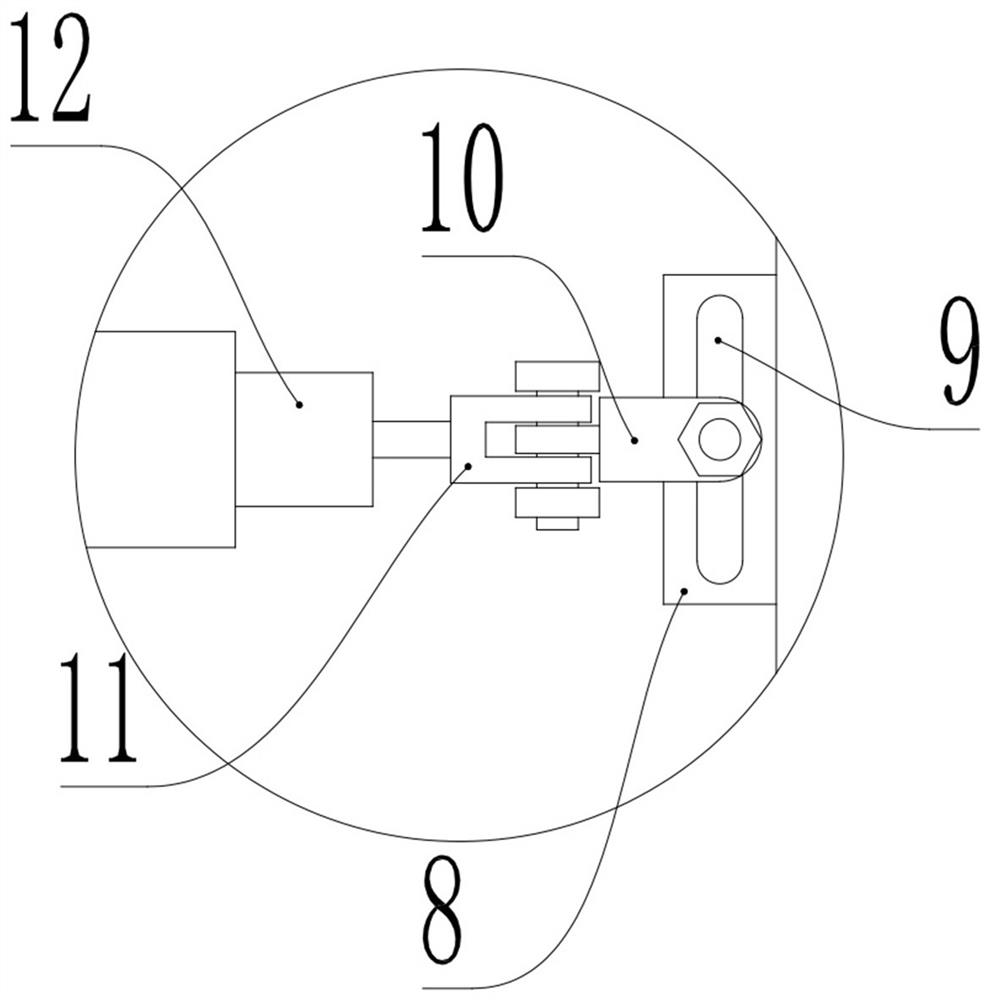

[0034] Please refer to Figure 1 to Figure 5 , figure 1 It is a structural schematic diagram of an embodiment of the present invention; figure 2 for figure 1 The enlarged schematic diagram at A; image 3 for figure 1 The enlarged schematic diagram at B; Figure 4 for figure 1 The enlarged schematic diagram at C; Figure 5 for figure 1 Enlarged schematic at D.

[0035] A kind of processing equipment for metal powder recycling handicrafts, including a distribution pipe 1, a frame, a swing assembly, a drying cylinder 16 and a hot air system 23, the distribution pipe 1 is used to spread the wet metal powder, and the frame is used to clean the entire processing equipment The swing assembly is used to swing the distribution pipe 1 back and forth, so that the metal powder is more evenly distributed. The drying cylinder 16 is the place where the metal powder is dried. The hot air system 23 provides hot air for the drying cylinder 16, thereby cooling the metal powder. The met...

Embodiment 2

[0050] Please refer to Figure 1 to Figure 5 , figure 1 It is a structural schematic diagram of an embodiment of the present invention; figure 2 for figure 1 The enlarged schematic diagram at A; image 3 for figure 1 The enlarged schematic diagram at B; Figure 4 for figure 1 The enlarged schematic diagram at C; Figure 5 for figure 1 Enlarged schematic at D.

[0051] This embodiment provides a metal powder recycling handicraft processing equipment, which is basically the same as the processing equipment in Embodiment 1, and the similarities will not be repeated. The difference is that the ball twist structure in this embodiment includes a cylinder seat 2, a sphere 3 With the ball seat 5, the top of the cloth pipe 1 is connected with the cylinder seat 2, and the cylinder seat 2 is connected with the spheroid 3, and the spheroid 3 is located in the hemispherical groove of the ball seat 5, and the ball seat 5 is provided with a ball cover 4 covering the spheroid 3, The...

Embodiment 3

[0055] Please refer to Figure 1 to Figure 5 , figure 1 It is a structural schematic diagram of an embodiment of the present invention; figure 2 for figure 1 The enlarged schematic diagram at A; image 3 for figure 1 The enlarged schematic diagram at B; Figure 4 for figure 1 The enlarged schematic diagram at C; Figure 5 for figure 1 Enlarged schematic at D.

[0056] This embodiment provides a kind of processing equipment for recycling metal powder handicrafts, which is basically the same as the processing equipment in Embodiment 1, and the similarities will not be repeated. Distributor 6.

[0057] In this embodiment, the discharge port of the distribution pipe 1 is connected to the upper opening of the drying cylinder 16, and a plurality of evenly distributed uniform distributors 6 are arranged at the discharge port of the distribution pipe 1. Usually, if the wet metal powder is in the Accumulation in the distribution pipe 1, its gravity will cause the metal powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com