Series filter bag type ultrasonic water mist laminating welding fume purification equipment

A purification equipment, ultrasonic technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., to achieve good air permeability and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

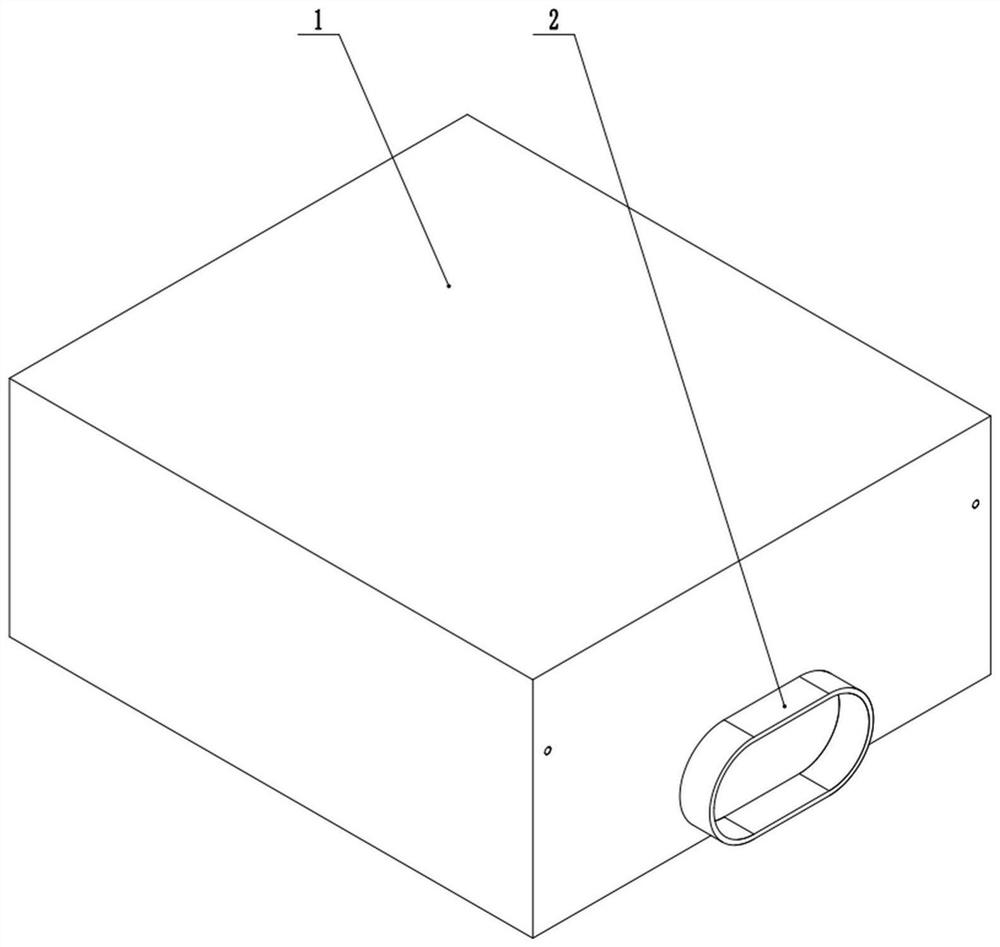

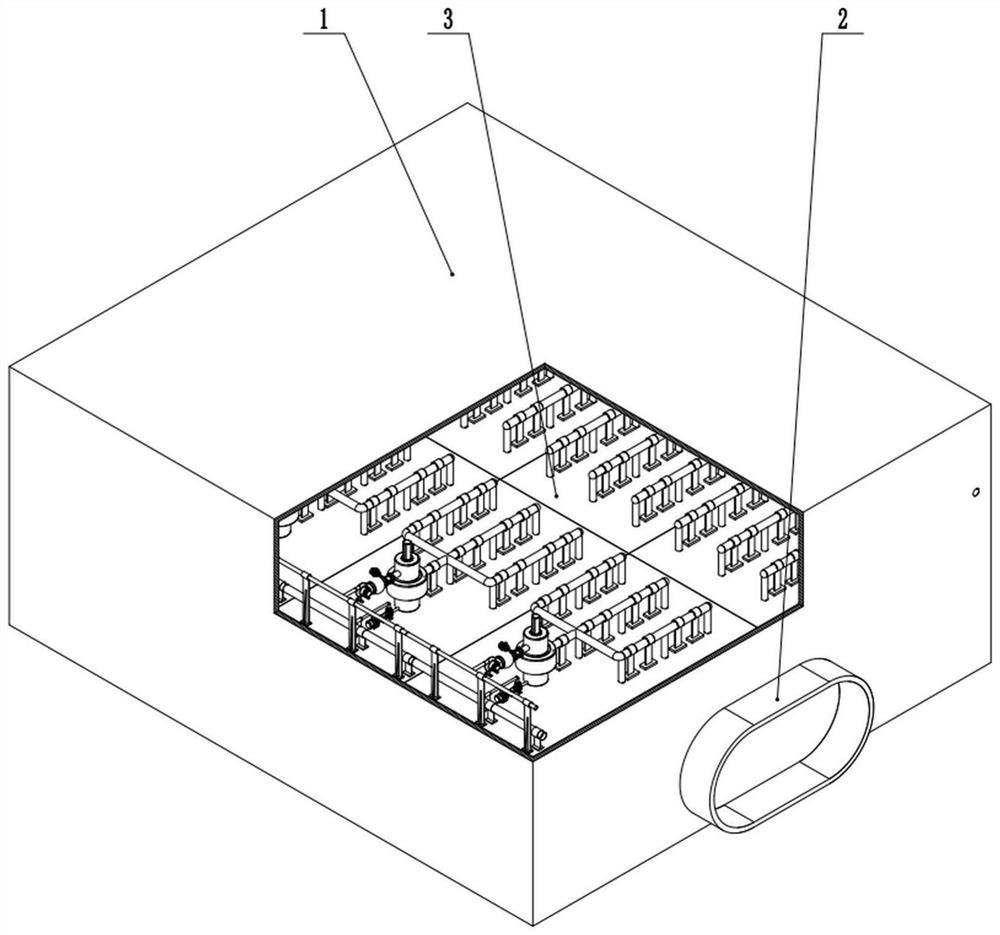

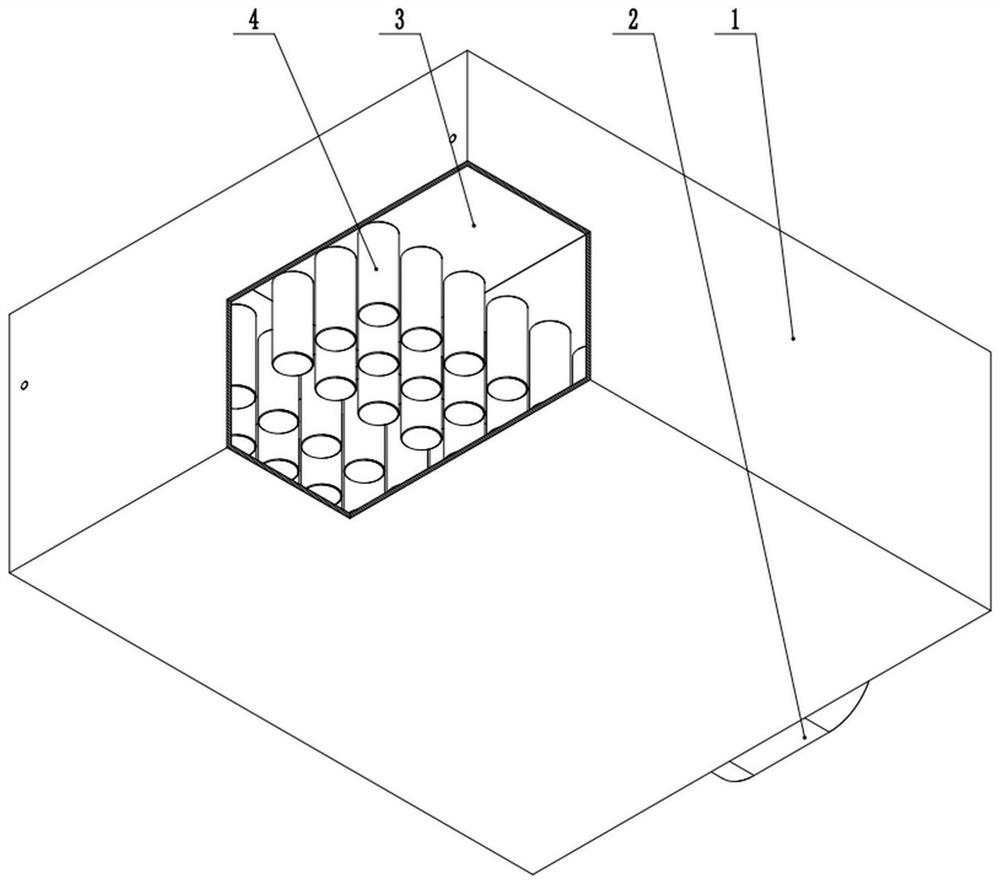

[0027] Such as Figure 1-8 As shown, the present invention provides a series filter bag type ultrasonic water mist film-coated welding fume purification equipment, which includes a housing 1, a plurality of groups of dust removal and purification components 3 are arranged in the housing 1, and an air inlet 2 is arranged at the lower part of the housing 1. The dust removal and purification components 3 each include a plurality of sets of cloth bags 4 at the bottom, and are characterized in that: an ultrasonic atomizer 5 is provided on the inner lower part of the housing 1; each of the dust removal and purification components 3 includes a pulse wind that can emit pulse wind The generator 8, a suction fan 9 for suction, also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com