Catalyst for catalyzing hydroxyaldehyde hydrogenation to prepare polyol and preparation and application methods of catalyst

An application method and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as environmental hazards, and achieve the effects of less Cu content, good stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 2.18g (9mmol, containing Cu 0.58g) Cu(NO 3 ) 2 ·3H 2 O and 5.35g (18mmol) Zn(NO 3 ) 2 ·6H 2 O, and the two were dissolved in 30mL deionized water;

[0043] (2) Weigh trimesic acid (H 3 BTC) (5mmol, 1.1g), and it was dissolved in 30mL absolute ethanol;

[0044] (3) Weigh 6g of 40-60 mesh shaped SiO 2 ;

[0045] (4) Mix the solutions obtained in steps (1) and (2) to obtain a suspension, and form SiO 2 added to the suspension;

[0046] (5) Transfer the mixture obtained in step (4) to a polytetrafluoroethylene-lined crystallization kettle, and react at 150° C. for 6 hours;

[0047] (6) The reaction mixture was taken out from the crystallization kettle, centrifuged, and the obtained solid was washed with deionized water, and then dried at 80° C. for 12 hours;

[0048] (7) the solid that step (6) obtains is put into tube furnace, under N 2 In the atmosphere, calcination at 400°C for 5 hours to obtain shaped SiO 2 Supported CuZn@C catalyst, denoted as Cu...

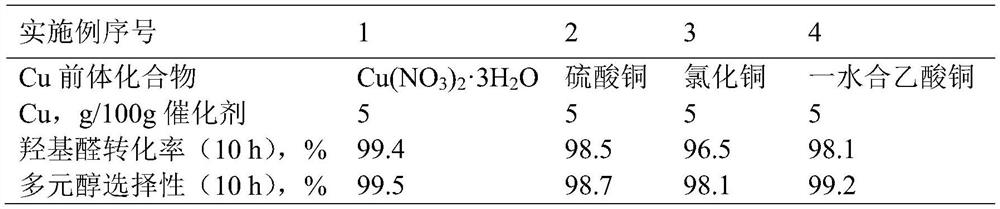

Embodiment 2-4

[0050] The same as the preparation method of Example 1, just change the Cu-containing precursor compound and the consumption in step (1) to be 1.44g copper sulfate, 1.21g cupric chloride and 1.80g copper acetate monohydrate, respectively, to obtain Example 2- 4 CuZn@C / SiO 2 catalyst.

[0051] CuZn@C / SiO prepared in embodiment 1-4 2 The catalyst is used in the reaction of hydrogenation of hydroxyaldehyde to polyols: 20ml of catalyst is loaded in a stainless steel tubular reactor with an inner diameter of 20mm, the reaction raw material is ethylbenzene solution of hydroxyaldehyde, the concentration of hydroxyaldehyde is 10wt%, and the reaction conditions are as follows: Hydrogen ketone moles Ratio 10:1, liquid hourly space velocity 0.4g (hydroxy aldehyde) g (catalyst) -1 h -1 , The reaction temperature is 80°C, and the reaction pressure is 2.5MPa. Under these conditions, the hydrogenation reaction of hydroxy aldehydes is carried out to obtain polyols.

[0052] Analysis of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com