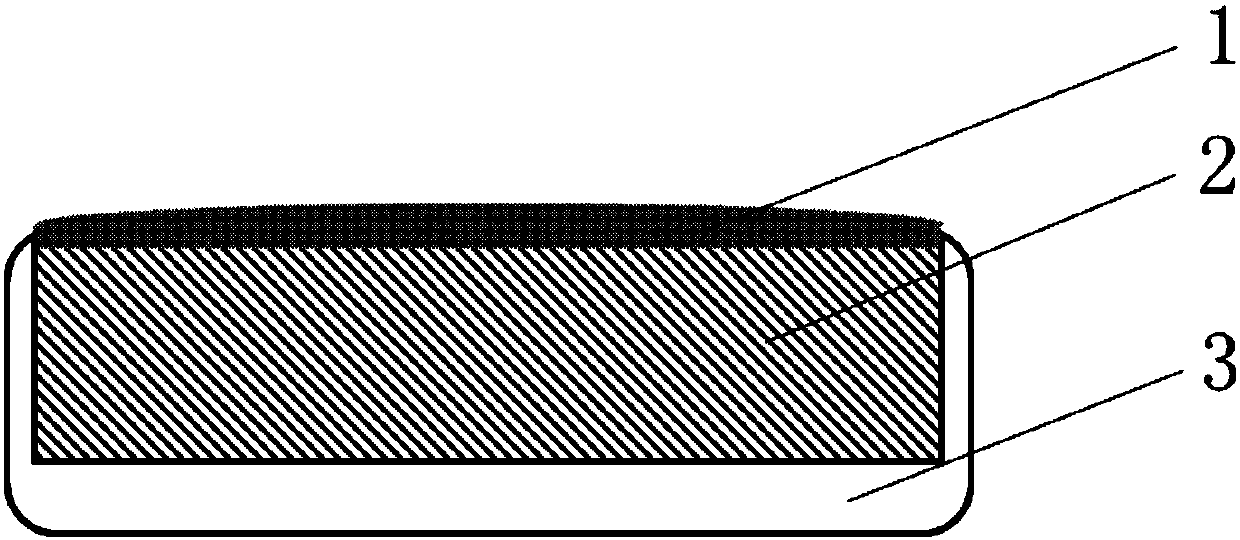

Novel high-performance repairable electric locomotive pantograph sliding plate and preparation method thereof

A technology for pantograph slides and composite coatings, which is applied in motor vehicles, electric vehicles, collectors, etc., and can solve the problems of irreparable pantograph slides, adhesive wear, and low mechanical strength of carbon slides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

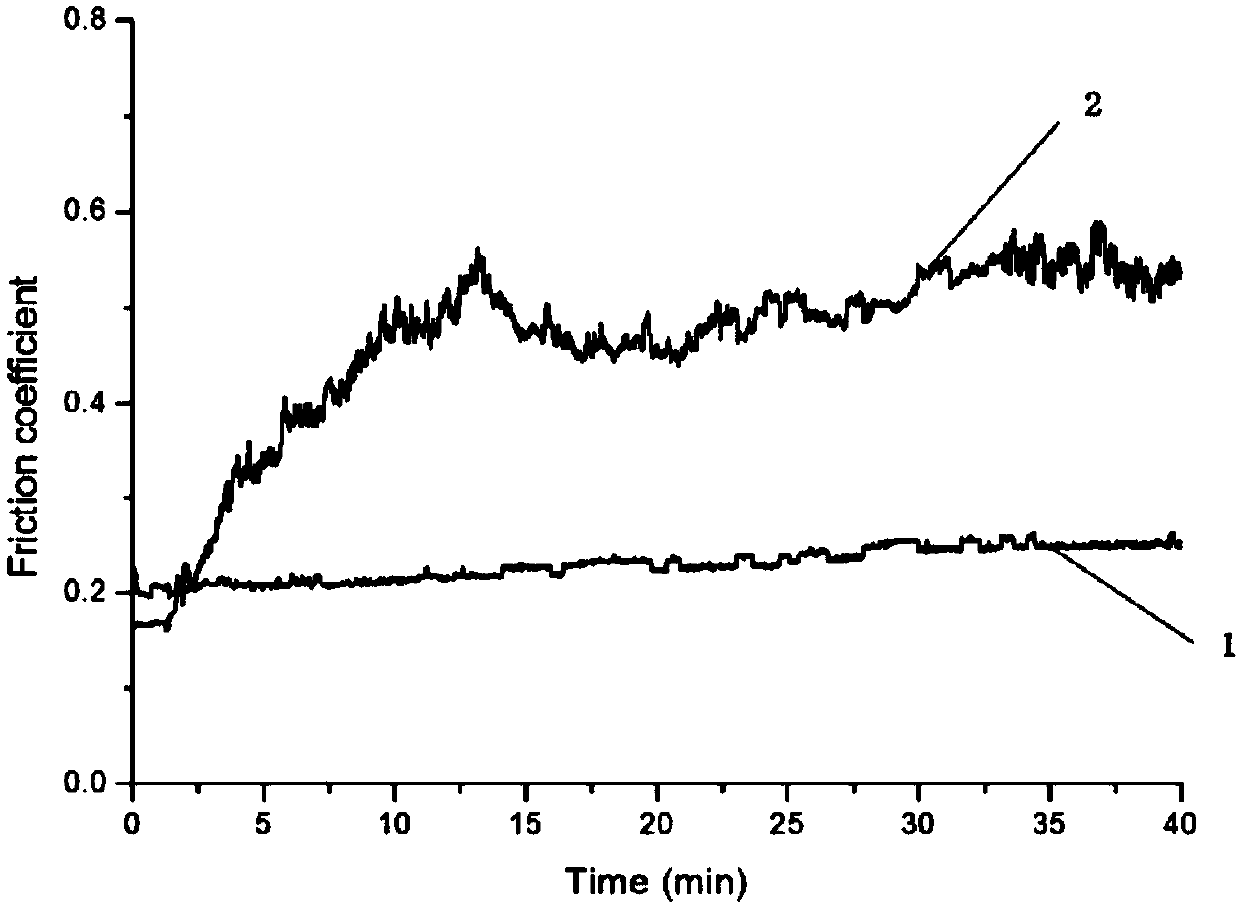

Examples

Embodiment 1

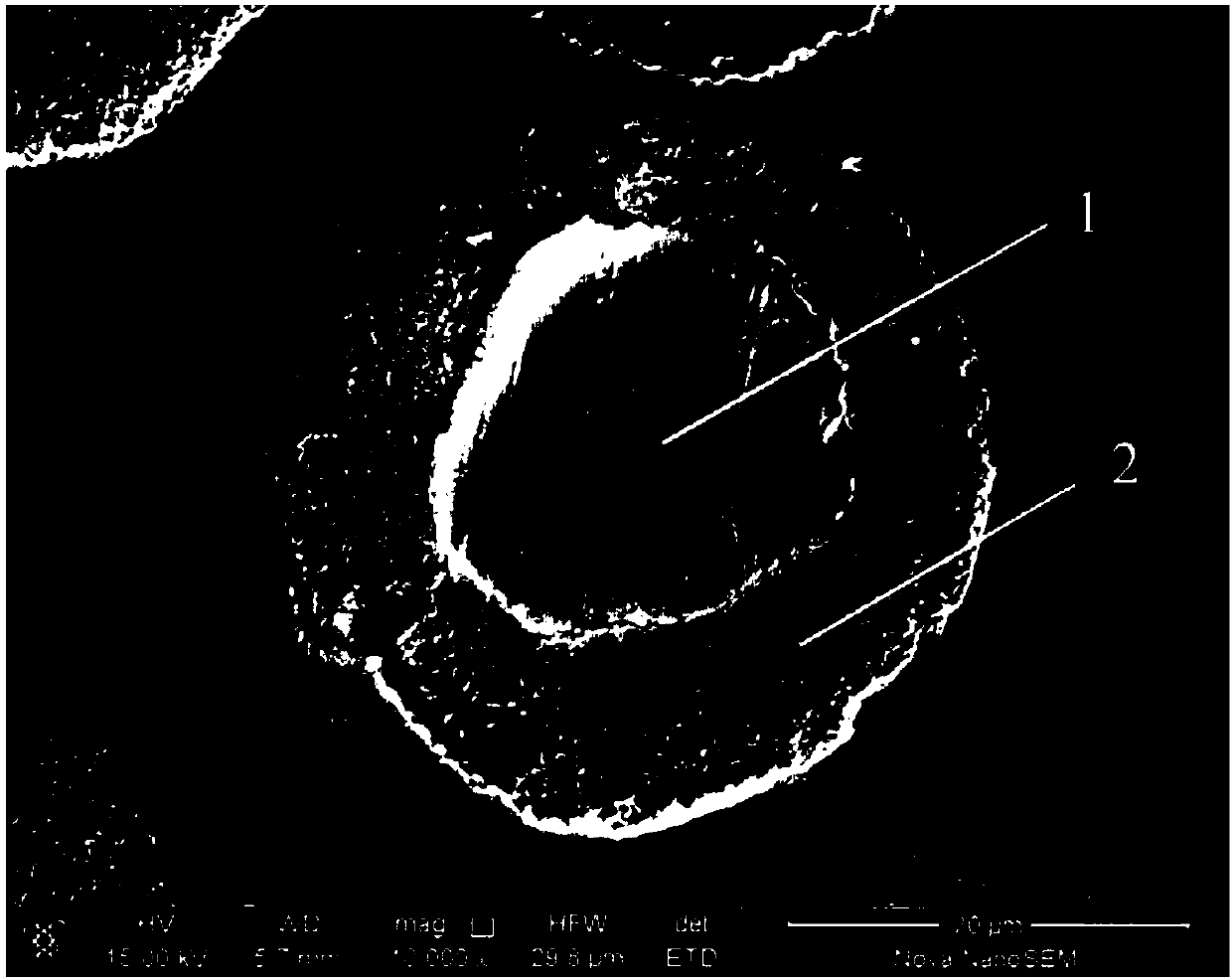

[0069] (1) Preparation of Cu-TiO by ultrasonic dispersion and spray drying 2 Composite powder

[0070] 1) In terms of mass percentage, take 20% of Cu powder with an average particle size of 15 μm and 80% of nano-TiO with an average particle size of 60 nm 2 The powder is doped and mixed to obtain a mixed powder;

[0071] 2) In terms of mass percentage, take 30% mixed powder, 68.5% deionized water and 1.5% binder PVA to mix and then stir to obtain mixed slurry;

[0072] 3) Place the mixed slurry obtained in step 2) in an ultrasonic reactor, and continuously ultrasonically disperse at a frequency of 45 Hz and a temperature of 50°C for 3 hours. During the ultrasonic dispersion, add 0.5% of the total weight of the slurry to the slurry % dispersant SND 6800;

[0073] 4) Use the LGZ-25 centrifugal spray dryer to spray and granulate the slurry obtained in step 3) by ultrasonic dispersion. The selected spray drying parameters are shown in Table 1. After spray granulation, Cu-TiO wit...

Embodiment 2

[0082] (1) Preparation of Cu-TiO by ultrasonic dispersion and spray drying 2 Composite powder

[0083] 1) In terms of mass percentage, 23% of Cu powder with an average particle size of 15 μm and 77% of nano-TiO with an average particle size of 60 nm 2 The powder is doped and mixed to obtain a mixed powder;

[0084] 2) In terms of mass percentage, take 33% mixed powder, 65% deionized water and 2% binder PVA, mix and stir respectively to obtain mixed slurry;

[0085] 3) Place the mixed slurry obtained in step 2) in an ultrasonic reactor, and continuously ultrasonically disperse for 3 hours at a frequency of 45Hz and a temperature of 50°C. During the ultrasonic dispersion process, add 0.8% of the total weight of the slurry to the slurry % dispersant SND 6800;

[0086] 4) Select LGZ-25 type centrifugal spray dryer to spray granulate the slurry obtained by ultrasonic dispersion in step 3), the selected spray drying parameters are as shown in Table 1 in Example 1, and obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com