Flat-mold hot extrusion process of nickel-based powder superalloy

A nickel-based superalloy and superalloy technology, applied in the field of powder metallurgy materials, can solve problems such as poor plasticity, and achieve the effects of reducing resistance, reducing surface quality deterioration, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

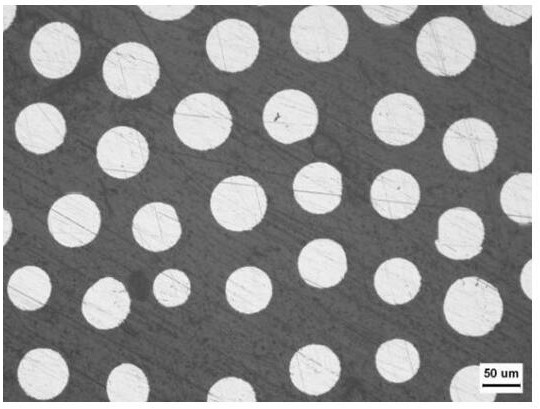

[0041] This example provides a flat-die hot extrusion process for nickel-based powder superalloy FGH4096. For the FGH4096 rod, the plasma rotating electrode method (PREP) is used to make powder, and the prepared powder is screened and electrostatically removed. Ensure that the powder particle size distribution range is 15~53μm, and the inclusion content is less than 3 pieces / 500g.

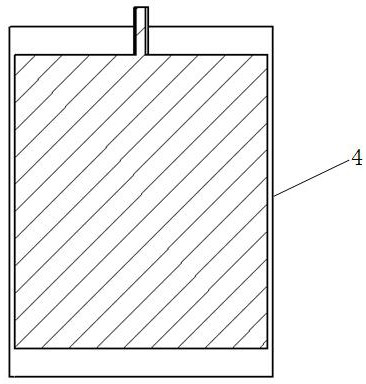

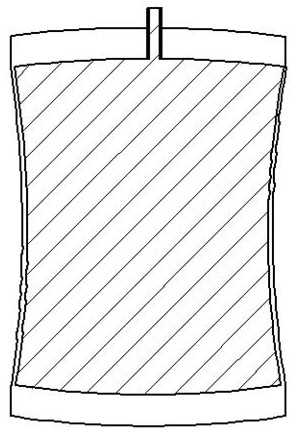

[0042] The prepared qualified powder is packed in a stainless steel sheath 4, and subjected to vacuum degassing and sealing welding treatment, wherein the stainless steel sheath 4 is metallurgically bonded 316 stainless steel.

[0043] Heat the stainless steel sheath 4 filled with powder to 1070° C. in a hot isostatic pressing furnace, keep it warm for 3 hours, and perform hot isostatic pressing to obtain a billet.

[0044] Apply antioxidant evenly to the surface of the billet (including the stainless steel sheath 4) obtained after hot isostatic pressing, then heat to 250°C, keep it warm for 3 hours,...

Embodiment 2

[0049] This example provides another flat-die hot extrusion process for nickel-based powder superalloy FGH4096. For FGH4096 rods, the plasma rotating electrode method (PREP) is used to make powder, and the prepared powder is screened and electrostatically removed. , to ensure that the powder particle size distribution range is 15~53μm, and the inclusion content is less than 3 / 500g.

[0050] The prepared qualified powder is packed in a stainless steel sheath 4, and subjected to vacuum degassing and sealing welding treatment, wherein the stainless steel sheath 4 is metallurgically bonded 316 stainless steel.

[0051] Heat the stainless steel sheath 4 filled with powder to 1100° C. in a hot isostatic pressing furnace, keep it warm for 4 hours, and obtain a billet after hot isostatic pressing.

[0052] Apply antioxidant evenly to the surface of the billet (including the stainless steel sheath 4) obtained after hot isostatic pressing, then heat to 220°C, keep it warm for 4 hours, a...

Embodiment 3

[0057] This example provides another flat-die hot extrusion process for nickel-based powder superalloy FGH4096. For FGH4096 rods, the plasma rotating electrode method (PREP) is used to make powder, and the prepared powder is screened and electrostatically removed. , to ensure that the powder particle size distribution range is 15~53μm, and the inclusion content is less than 3 / 500g.

[0058] The prepared qualified powder is packed in a stainless steel sheath 4, and subjected to vacuum degassing and sealing welding treatment, wherein the stainless steel sheath 4 is metallurgically bonded 316 stainless steel.

[0059] Heat the stainless steel sheath 4 filled with powder to 1130° C. in a hot isostatic pressing furnace, keep it warm for 2 hours, and perform hot isostatic pressing to obtain a billet.

[0060] Apply an antioxidant evenly to the surface of the billet (including the stainless steel sheath 4) obtained after hot isostatic pressing, then heat to 200°C, keep it warm for 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com