Composite-vision-based intelligent flat plate groove cutting system and method

An intelligent cutting and visual technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low cutting accuracy, failure to meet welding requirements, enlargement of workpiece size deviation, etc., to ensure stability and reliability, Guaranteed accuracy, guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

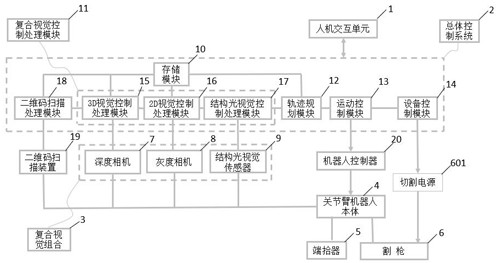

[0055] like figure 1 As shown, a compound vision-based intelligent cutting system for flat bevels designed by the present invention is characterized in that it includes a human-computer interaction unit 1, an overall control system 2, a compound vision combination 3 connected to the overall control system, and an articulated arm robot Body 4, end picker 5 and torch 6 connected with articulated arm robot body 4;

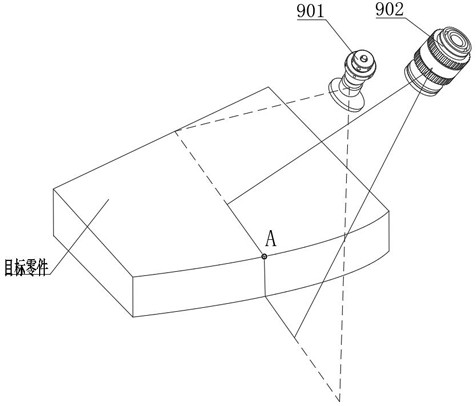

[0056] The composite vision combination 3 includes a depth camera 7, a gray scale camera 8 and a structured light vision sensor 9;

[0057] The overall control system 2 includes a storage module 10, a compound vision control processing module 11, a trajectory planning module 12, a motion control module 13 and an equipment control module 14;

[0058] The storage module 10 is used to store 3D model data and cutting process data of all parts to be cut; the storage module can also be set in the upper database.

[0059] The compound vision control processing module 11 in...

Embodiment 2

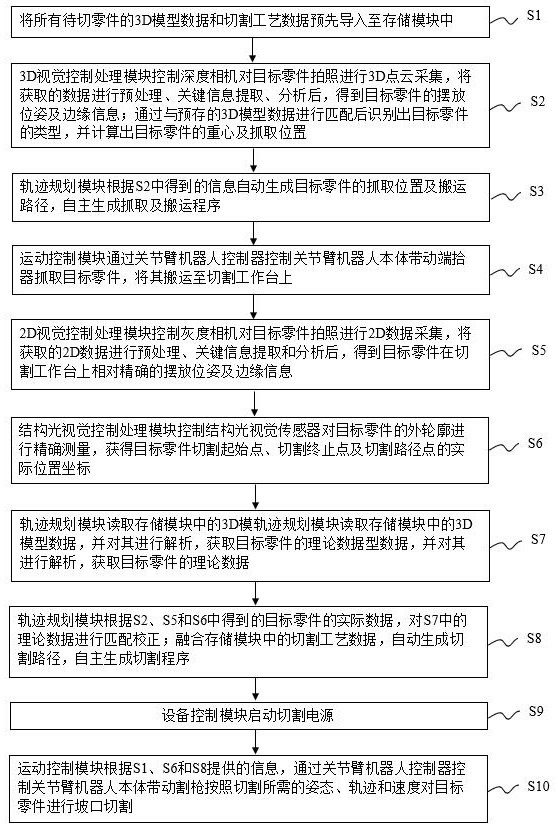

[0069] like figure 2 As shown, a compound vision-based intelligent cutting method for flat bevels includes the following steps:

[0070] S1, pre-importing the 3D model data and cutting process data of all parts to be cut into the storage module 10;

[0071] S2, the 3D vision control processing module 15 controls the depth camera 7 to take pictures of the target part to collect 3D point clouds, preprocess the acquired data, extract key information, and analyze to obtain the position and edge information of the target part; After matching with the pre-stored 3D model data, identify the type and position of the target part, and calculate the center of gravity and grasping position of the target part;

[0072] S3, the trajectory planning module 12 automatically generates the grasping position and the conveying path of the target part according to the information obtained in S2, and autonomously generates the grasping and conveying program;

[0073] S4, the motion control module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com