Preparation method of high-strength porous ceramic ocular prosthesis seat

A technology for porous ceramics and prosthetic eye sockets, which is applied in the preparation of porous ceramic spherical prosthetic eye sockets and the field of preparation of high-strength porous ceramic spherical prosthetic eye sockets, can solve the problems of complex preparation process, high density, and difficult product processing, etc. The process is simple, the development prospect is good, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

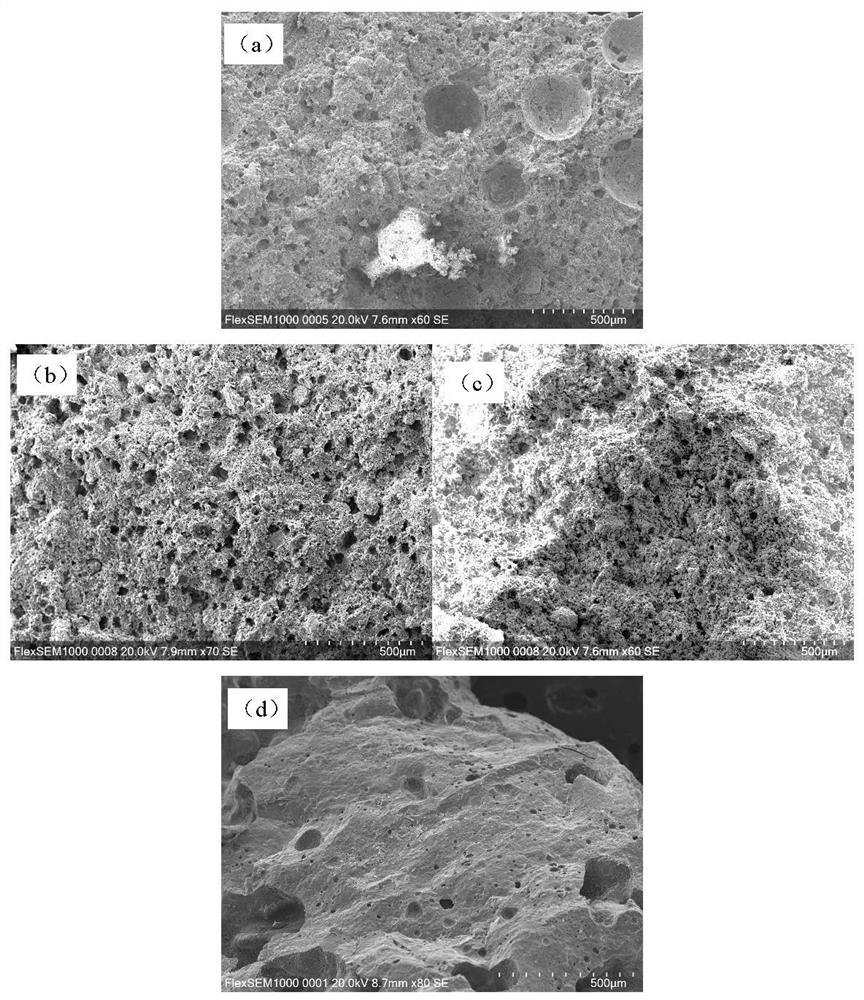

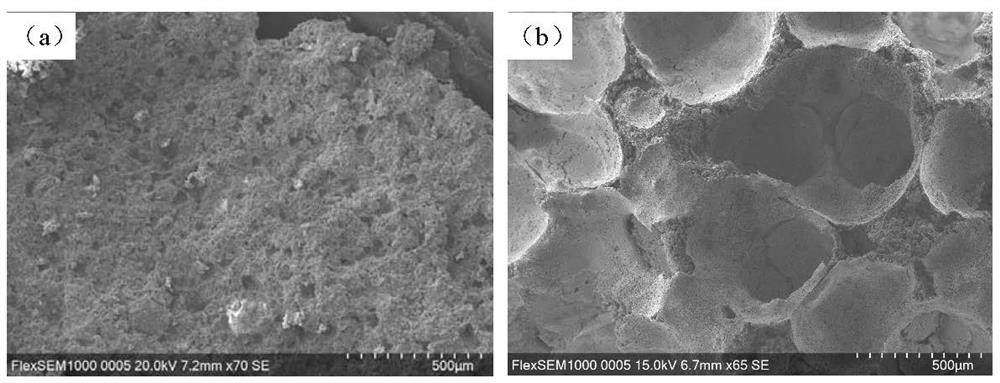

[0034] Stir 6gHA+4gCS bioceramic powder, 0.8g hydroxypropyl methylcellulose, 0.5g PMMA balls (size ~ 100μm), and 4.84g water to form a high-viscosity mixed ceramic slurry; pour the high-viscosity slurry into a rubber mold for molding , 6 hours after air drying, the green body (compressive strength of 4.8MPa) was obtained; the green body was first debonded at 600°C for 2 hours to remove the pore-forming agent, and then sintered at 1250°C for 2h to obtain a porous structure with a three-dimensional interconnected pore structure. Ceramic spherical prosthetic eye socket.

Embodiment 2

[0036] Stir 8gHA+2gCS bioceramic powder, 0.5g hydroxypropyl methylcellulose, 1gPMMA ball (size ~ 250μm), and 17.25g water to form a high-viscosity mixed ceramic slurry; pour the high-viscosity slurry into a rubber mold for molding, After 12 hours of air drying, the green body (compression strength of 1.3MPa) was obtained; the green body was first debonded at 600°C for 2 hours to remove the pore-forming agent, and then sintered at 1100°C for 2 hours to obtain a porous ceramic spherical shape with a three-dimensional interconnected pore structure. Prosthetic eye seat.

Embodiment 3

[0038] Stir 7gHA+3gCS bioceramic powder, 0.5g hydroxypropyl methylcellulose, 1gPMMA ball (size ~250μm), and 7.7g water to form a high-viscosity mixed ceramic slurry; pour the high-viscosity slurry into a rubber mold for molding, After air drying for 8 hours, the green body (compressive strength is 3.9MPa) was obtained; the green body was first debonded at 600°C for 2 hours to remove the pore-forming agent, and then sintered at 1250°C for 1 hour to obtain a porous ceramic with a three-dimensional interconnected pore structure Spherical prosthetic eye seat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com