Hydraulic accumulator inflation device based on oilfield petrochemical engineering and inflation method thereof

A technology of hydraulic accumulators and inflatable devices, which is applied to container filling methods, container discharge methods, pressure vessels, etc., can solve problems such as narrow application range, unfavorable use, and air pressure reduction, and achieve wide application range and good use effect , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

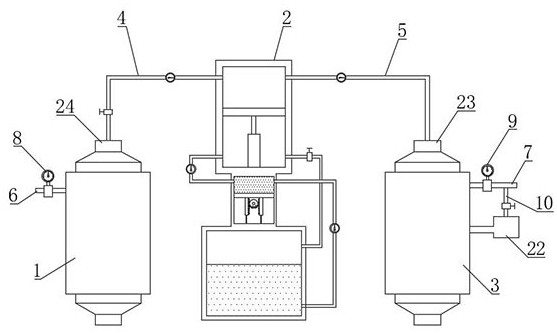

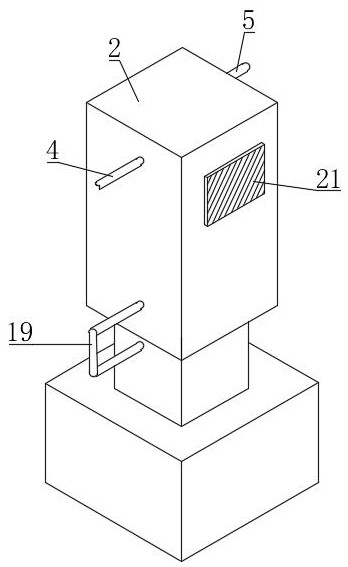

[0055] Such as Figure 1-6 As shown, the hydraulic accumulator charging device based on oil field petrochemical proposed by the present invention includes a nitrogen tank 1, an accumulator 3, a gas delivery pipe 4, an inflation pipe 5, a first connection assembly 23 and a second connection assembly 24, and the gas delivery pipe 4 is connected with the nitrogen tank 1 through the second connection assembly 24, the gas charging pipe 5 is connected with the accumulator 3 through the first connection assembly 23, the nitrogen tank 1 is equipped with a first air guide tube 6, and the first air guide tube 6 is equipped with a second An air pressure sensor 8, and the other end of the first air guide tube 6 is closed, the first air pressure sensor 8 detects the air pressure in the nitrogen tank 1, the second air guide tube 7 is installed on the accumulator 3, the second air guide tube 7 is equipped with a second air pressure sensor 9, and the other end of the second air guide tube 7 i...

Embodiment 2

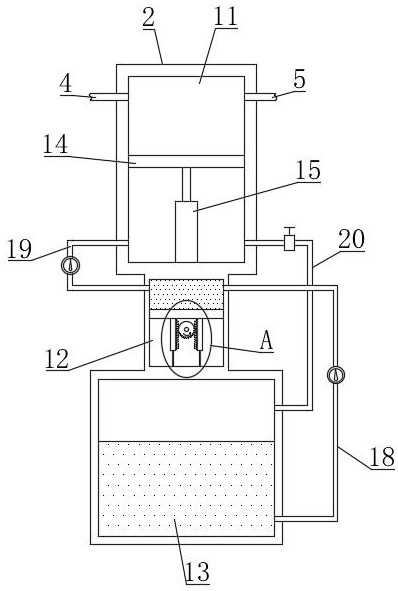

[0065] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that a guide pull-down assembly 15 is installed on the bottom of the first piston plate 14, and the guide pull-down assembly 15 includes a first connecting cylinder 1501, a second connecting cylinder 1502, a stop ring 1503, The vertical bar 1504 and the first spring 1505, the first connecting cylinder 1501 is vertically arranged and fixedly installed on the bottom of the first piston plate 14 by bolts, the opening of the first connecting cylinder 1501 is downward, the second connecting cylinder 1502 is vertically arranged and Installed on the bottom of the pressurized chamber 11 by bolts, the opening of the second connecting cylinder 1502 faces upward, and the first connecting cylinder 1501 is inserted downward into the second connecting cylinder 1502, and the vertical rod 1504 is vertically arranged on the second connecting cylinder 1502 insert into the first connecting cylinder 1501...

Embodiment 3

[0068] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that a pressure relief pipe 10 is vertically installed at the end of the second air guide pipe 7, and the other end of the pressure relief pipe 10 is connected with a slow release box 22, and the pressure relief A pressure relief valve is installed on the pipe 10. When the air pressure in the accumulator 3 is greater than a certain value, the pressure relief pipe 10 will discharge the gas inside the accumulator 3 to relieve pressure and prevent the internal air pressure of the accumulator 3 from Excessively high and explode, avoid to bring potential safety hazard; Sustained release box 22 comprises box body 2201, grid plate 2202, fixed rod 2203 and the 3rd spring 2204, and the top of box body 2201 is communicated with pressure relief pipe 10, and the top of box body 2201 The bottom is open, and the inner sides of the box body 2201 are equipped with fixed rods 2203 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com