Preparation method of diamond-metal high-temperature solid-state interface reaction sample

An interfacial reaction and sample preparation technology, applied in the preparation of test samples, chemical method analysis, sampling, etc., can solve problems such as environmental pollution and powder oxidation, and achieve the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

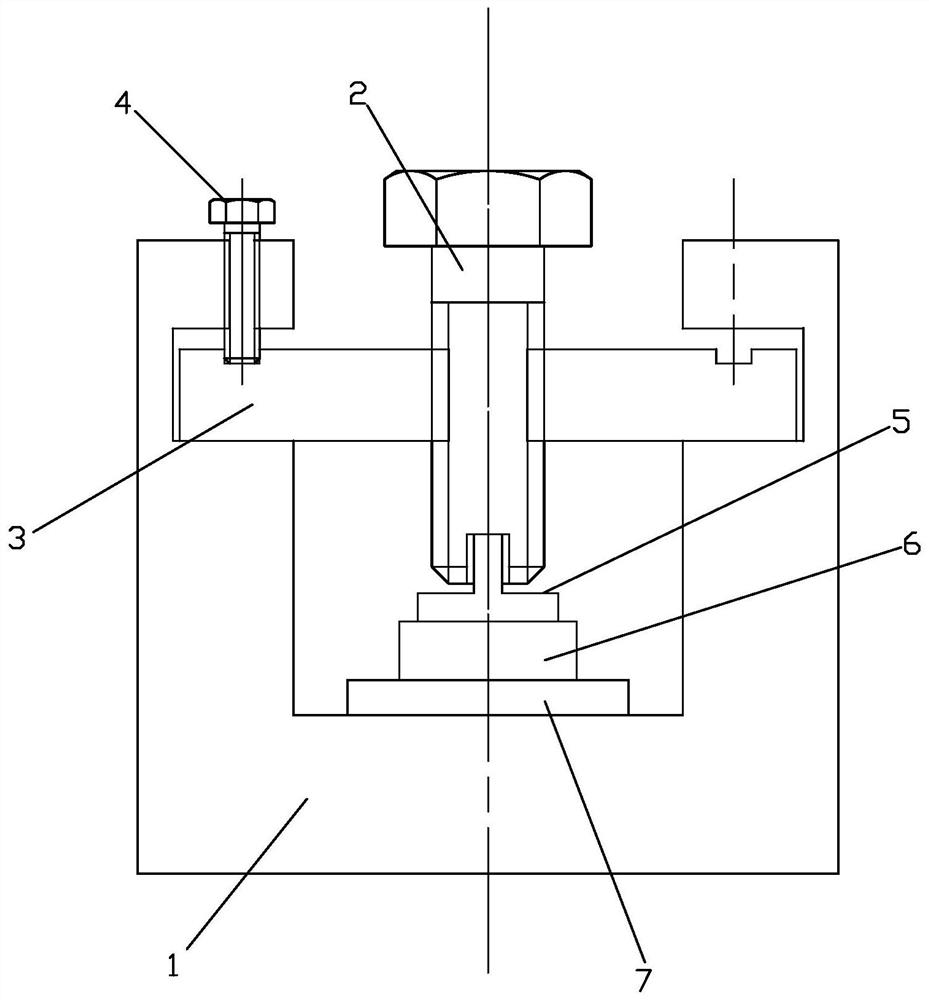

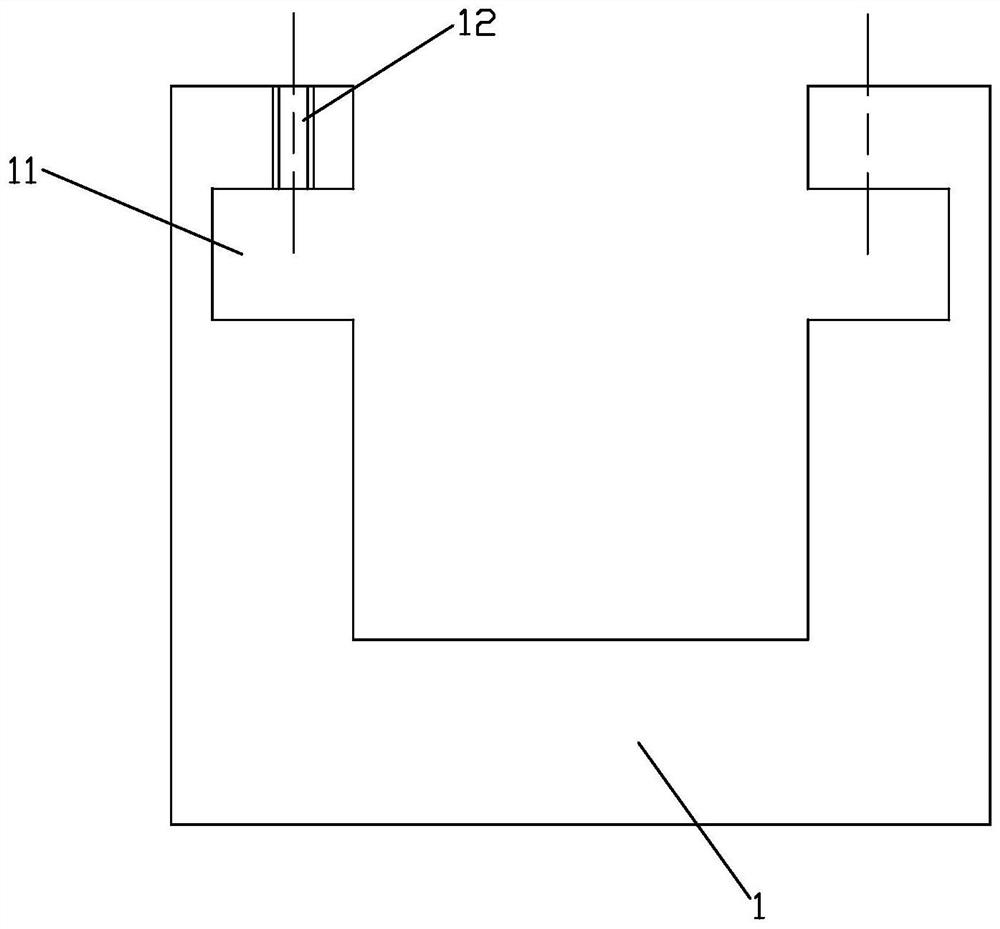

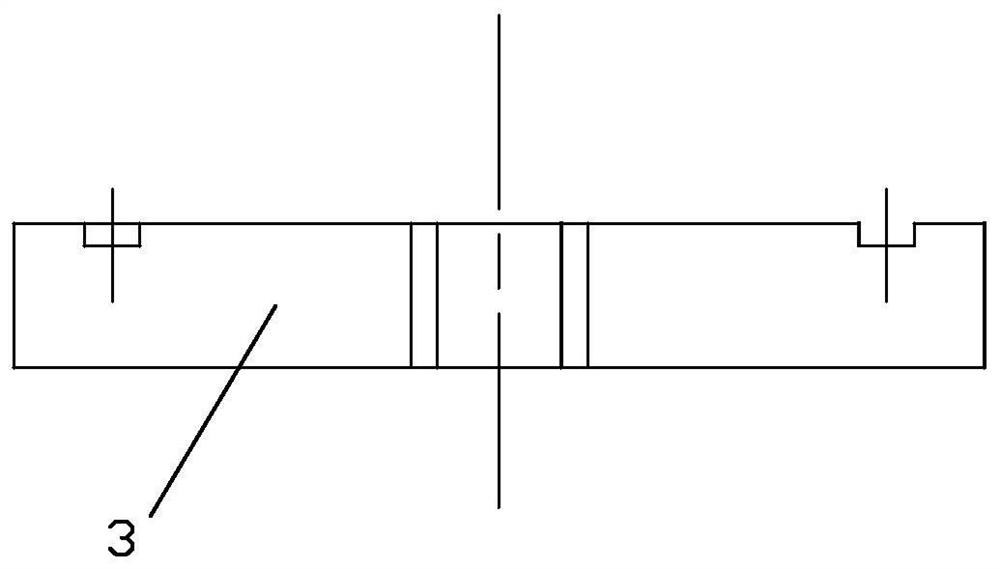

[0038] Please check Figure 1 to Figure 5 , The clamping device includes a stage 1, a sample fixing nail 2, a nail seat 3, a nail seat fixing nail 4 and a fixed pressure head 5.

[0039] The object stage 1 comprises a body and two columns fixed on the platform body at intervals horizontally, and the facing side walls of the two columns are concavely provided with loading grooves 11; the two ends of the nail base 3 are loaded into the device into the groove 11; the sample fixing nail 2 can be adjusted up and down through the nail seat 3, the lower end of the sample fixing nail 2 is connected to the fixed pressure head 5, the diamond 6 and the metal 7 are stacked up and down on the table body, and the sample fixing nail is rotated 2. The fixed indenter 5 is pressed against the diamond 6. On the one hand, it can adapt to different sample heights. On the other hand, it can adjust the pressing force to adapt to different hardness metals; The through groove 12 of the nail holder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com